Porous LLZO ceramic powder inhibitor for thermal battery electrolyte and preparation method of porous LLZO ceramic powder inhibitor

A technology of ceramic powder and electrolyte, applied in the direction of non-flowing electrolyte, chemical instruments and methods, delayed action cells, etc., can solve the problems affecting the power performance of thermal batteries, less salt consumption, and limited porosity of LLZO, etc., to achieve improvement The effect of instantaneous power output performance, easy operation, extended service life and storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

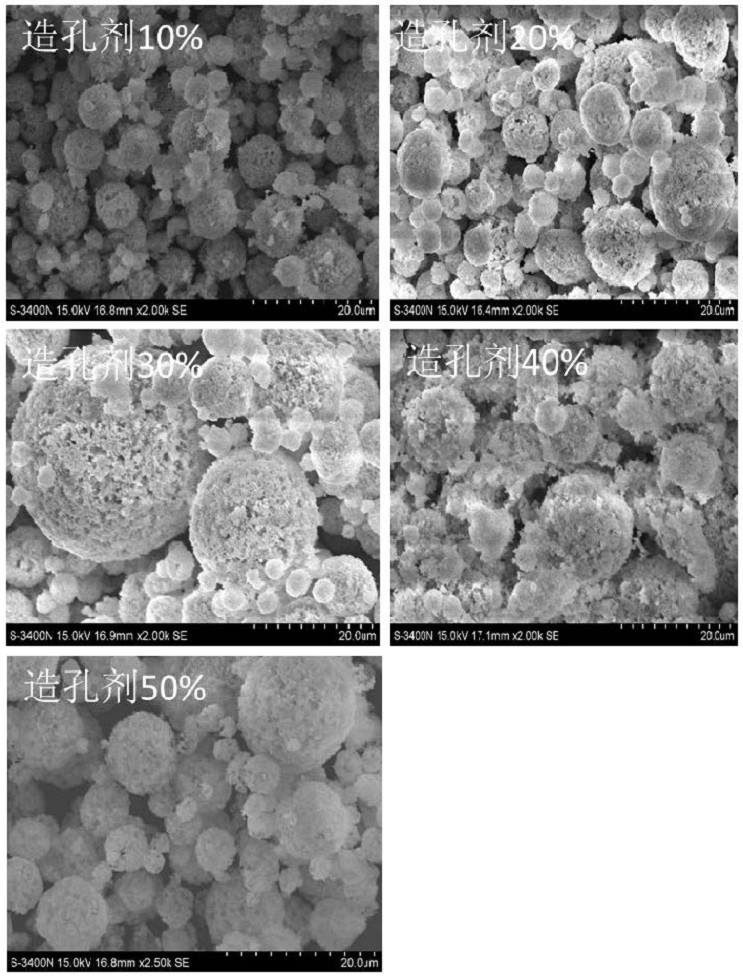

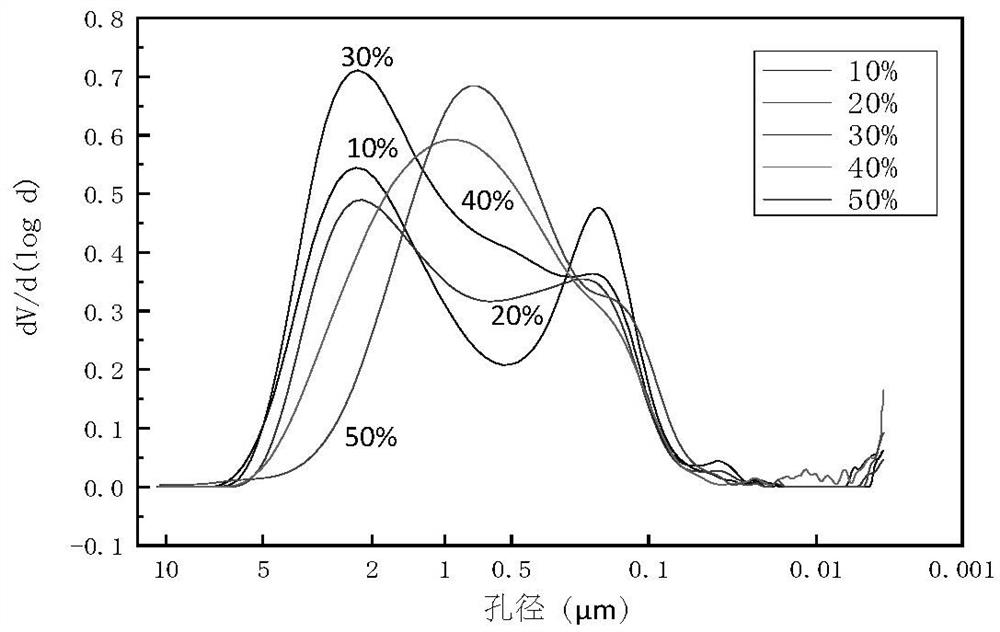

[0049]Mix LLZO ceramic powder and anhydrous isopropanol solvent at a mass ratio of 1:10, grind for 3 hours at a speed of 1800r / min with a high-speed ball mill, dry in a blast oven at 70°C, and pass through a 80-mesh sieve to fine chemical backup. The above-mentioned refined ceramic powder, polyethylene glycol, lithium hydroxide, and water are configured into a slurry with a solid content of 20%, and the pH of the slurry is adjusted to 11. Toner pore builder, stir well. A spray device with a nozzle diameter of 1mm was used to inject samples, the feed flow rate was controlled at 0.5mL / min, the inlet temperature was 200°C, and the outlet temperature was 82°C. The sprayed powder was collected and calcined at 600° C. for 3 hours in an air atmosphere, and the powder was taken out and placed in an air atmosphere with a temperature of 25° C. and a humidity of 30% for 6 hours as a powder after surface treatment. Prepare an alcohol solution of aluminum triethoxide with a concentration...

Embodiment 2

[0052] Mix LLZO ceramic powder and anhydrous isopropanol solvent at a mass ratio of 1:10, grind for 3 hours with a high-speed ball mill at a speed of 1800r / min, dry in a blast oven at 70°C, and pass through a 80-mesh sieve Refine spare. The above-mentioned refined ceramic powder, polyethylene glycol, lithium hydroxide, and water are configured into a slurry with a solid content of 20%, adjust the pH of the slurry to 11, and then add carbon with a mass fraction of 20% and a diameter of 500nm. Powder pore builder, mix well. A spray device with a nozzle diameter of 1 mm was used for sample injection, the feed flow rate was controlled at 0.5 mL / min, the inlet temperature was 200 °C, and the outlet temperature was 82 °C. The sprayed powder was collected and calcined at 600° C. for 3 hours in an air atmosphere, and the powder was taken out and placed in an air atmosphere with a temperature of 25° C. and a humidity of 30% for 6 hours as a powder after surface treatment. Configure a...

Embodiment 3

[0054] Mix LLZO ceramic powder and anhydrous isopropanol solvent at a mass ratio of 1:10, grind for 3 hours with a high-speed ball mill at a speed of 1800r / min, dry in a blast oven at 70°C, and pass through a 80-mesh sieve Refine spare. The above refined ceramic powder, polyethylene glycol, lithium hydroxide, and water are configured into a slurry with a solid content of 20%, adjust the pH of the slurry to 11, and then add carbon powder with a mass fraction of 30% and a diameter of 500nm Pore-forming agent, stir well. A spray device with a nozzle diameter of 1 mm was used for sample injection, the feed flow rate was controlled at 0.5 mL / min, the inlet temperature was 200 °C, and the outlet temperature was 82 °C. The sprayed powder was collected and calcined at 600° C. for 3 hours in an air atmosphere, and the powder was taken out and placed in an air atmosphere with a temperature of 25° C. and a humidity of 30% for 6 hours as a powder after surface treatment. Configure an al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com