A kind of treatment method of oil sludge sand

A treatment method and technology of oily sludge sand, applied in sludge treatment, water/sludge/sewage treatment, treatment of hydrocarbon oil, etc., can solve the problem of oil content not meeting national standards, etc., and achieve comprehensive recycling, short cycle, The effect of accelerating the rate of catalytic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

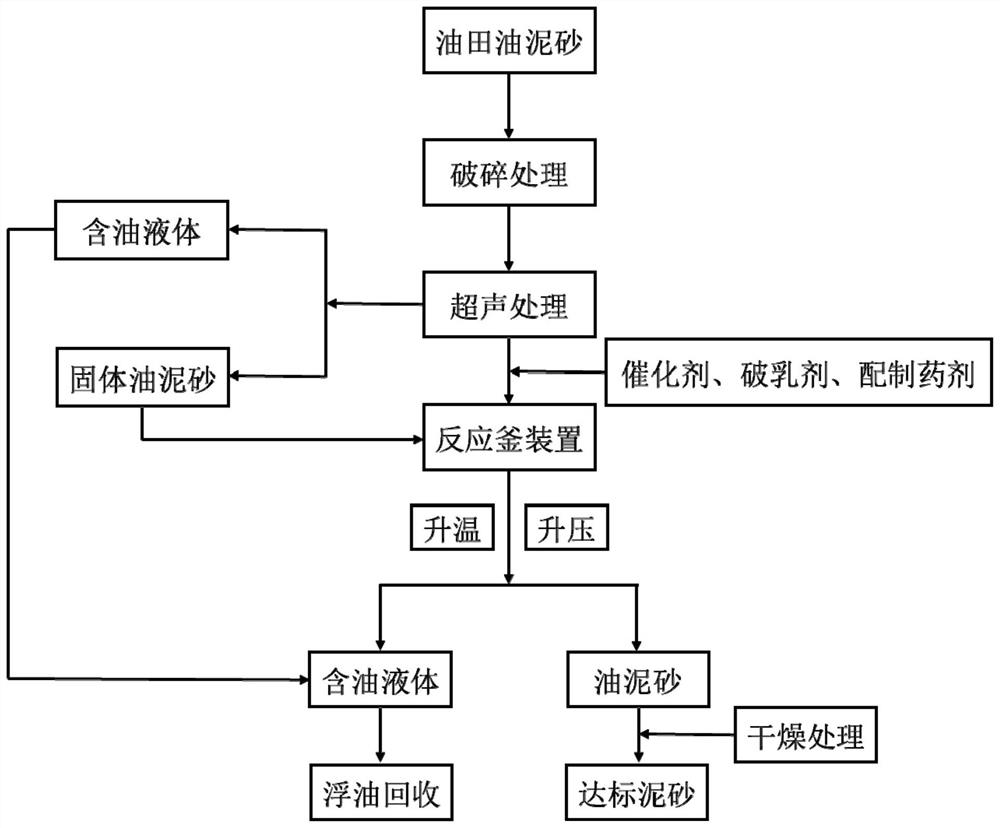

[0040] The present embodiment provides a kind of processing method of oil sludge sand, and concrete steps are as follows:

[0041] (1) Weigh 500g of oil sludge sand (raw material provided by COSL) for crushing treatment. After crushing, sieve the oil sludge sand with an aperture range of 0.075-2mm into a clean beaker, add 1L of clean water and put it into an ultrasonic instrument. Ultrasonic treatment, the ultrasonic frequency is 20kHz, the ultrasonic temperature is 50°C, and the ultrasonic time is 30min. The ultrasonic cavitation is used to remove the oil on the surface of the oil sludge and sand, and the oily liquid in the upper layer is recycled.

[0042] (2) Put the ultrasonically treated solid oil sludge into the reaction kettle, add 250g of deoiling catalyst and 250g of demulsification catalyst, wherein, in the deoiling catalyst, secondary alkyl sulfonate SAS, fatty acid methyl ester sulfonate sodium MES, fatty acid Methyl Ethoxylate FMEE, Sodium Dodecylbenzene Sulfonate...

Embodiment 2

[0050] The present embodiment provides a kind of processing method of oil sludge sand, and concrete steps are as follows:

[0051] (1) Weigh 50g of oil sludge sand (raw material provided by COSL) for crushing treatment, and then sieve the oil sludge sand with an aperture range of 0.075-2mm into a clean beaker, add 100ml of water and put it into an ultrasonic instrument for further processing Ultrasonic treatment, the ultrasonic frequency is 20kHz, the ultrasonic temperature is 20°C, and the ultrasonic time is 10min. The ultrasonic cavitation is used to remove the oil on the surface of the oil sludge and sand, and the oily liquid in the upper layer is recycled.

[0052] (2) Put the ultrasonically treated solid oil sludge into the reaction kettle, add 5g of deoiling catalyst and 5g of demulsification catalyst, wherein, in the deoiling catalyst, secondary alkyl sulfonate SAS, fatty acid methyl ester sulfonate sodium MES, fatty acid Methyl Ethoxylate FMEE, Sodium Dodecylbenzene Su...

Embodiment 3

[0056] The present embodiment provides a kind of processing method of oil sludge sand, and concrete steps are as follows:

[0057] (1) Weigh 1000g of oil sludge sand (raw material provided by COSL) for crushing treatment, and then sieve the oil sludge sand with an aperture range of 0.075-2mm into a clean beaker, add 2L of clean water and put it into an ultrasonic instrument for Ultrasonic treatment, the ultrasonic frequency is 40kHz, the ultrasonic temperature is 80°C, and the ultrasonic time is 120min. The ultrasonic cavitation is used to remove the oil on the surface of the oil sludge and sand, and the oily liquid in the upper layer is recycled.

[0058] (2) Put the ultrasonically treated solid oil sludge into the reactor, add 500g of deoiling catalyst and 500g of demulsification catalyst, wherein, in the deoiling catalyst, secondary alkyl sulfonate SAS, fatty acid methyl ester sulfonate sodium MES, fatty acid Methyl Ethoxylate FMEE, Sodium Dodecylbenzene Sulfonate LAS, Sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com