Method for growing gradient doped Yb: YAG single crystal

A gradient doping and single crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of affecting crystal quality, uneven heating, high local heating, etc., to avoid fluid vibration, avoid crystal defects, The effect of reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

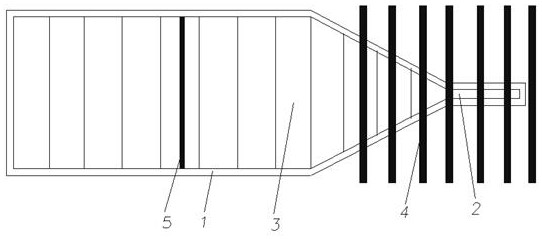

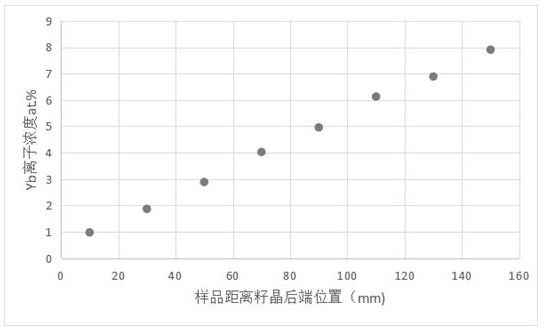

[0044] Prepare 200g of 1%, 2%, 3%, 4%, 5%, 6%, 7%, and 8% Yb:YAG raw materials respectively, mix them separately, and then sinter at 1500°C for 1 hour. The raw materials are put into the boat-shaped molybdenum crucible (160*100*40mm) from front to back according to the concentration gradually increasing, and the pure YAG seed crystal is put into the crucible head. Put the crucible and raw materials into the split movable heater in the single crystal furnace. The connection between the seed crystal and the raw material is located in the middle of the heater. Seal the heater and start drawing a high vacuum.

[0045] Wait until the vacuum reaches 2*10 -3 At Pa, turn on the heating power supply, and the heater starts to heat up. The heater consists of five groups of heating units, the middle group of heating units heats up to 24kW, the adjacent two groups of heating units heat up to 22kW, and the outermost two groups of heating units heat up to 21kW. After 3 hours of heating, ...

Embodiment 2

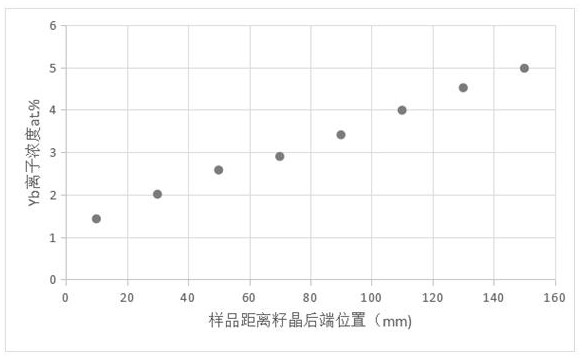

[0048] Prepare 200g each of 1.5%, 2%, 2.5%, 3%, 3.5%, 4%, 4.5%, and 5% Yb:YAG raw materials, mix them separately and sinter at 1500°C for 1 hour, and sinter the raw materials with different concentrations Put them into a boat-shaped molybdenum crucible (160*100*40mm) from front to back according to the concentration gradually increasing, and put pure YAG seed crystals into the crucible head. Put the crucible and raw materials into the split movable heater in the single crystal furnace. The connection between the seed crystal and the raw material is located in the middle of the heater. Seal the heater and start drawing a high vacuum.

[0049] Wait until the vacuum reaches 5*10 -3 At Pa, turn on the heating power supply, and the heater starts to heat up. The heater consists of five groups of heating units, the middle group of heating units heats up to 23.9kW, the adjacent two groups of heating units heat up to 21.8kW, and the outermost two groups of heating units heat up to 2...

Embodiment 3

[0052] Prepare 150g each of 2%, 4%, 6%, 8%, 10%, 12%, 14%, 16%, 18%, and 20% Yb:YAG raw materials respectively, mix them separately and sinter at 1500°C for 1 hour, Put the sintered raw materials with different concentrations into the boat-shaped molybdenum crucible (180*90*35mm) from front to back according to the concentration gradually increasing, and put the pure YAG seed crystal into the crucible head. Put the crucible and raw materials into the split movable heater in the single crystal furnace. The connection between the seed crystal and the raw material is located in the middle of the heater. Seal the heater and start drawing a high vacuum.

[0053] Wait until the vacuum reaches 1*10 -3 At Pa, turn on the heating power supply, and the heater starts to heat up. The heater is composed of 9 groups of heating units. The target power of the heating units from the middle to both sides is 23.6kW, 23.2kW, 23.1kW, 23kW, and 23kW. When the temperature rises for 0.6 hours, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com