An On-Line Voltage Drop Monitoring Circuit for Junction Temperature Monitoring

A technology for conducting voltage drop and monitoring circuits. It is applied in the direction of measuring electricity, measuring electrical variables, and measuring devices. It can solve problems such as high cost and main circuit interference, and achieve the effects of optimizing measurement errors, reducing costs, and suppressing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

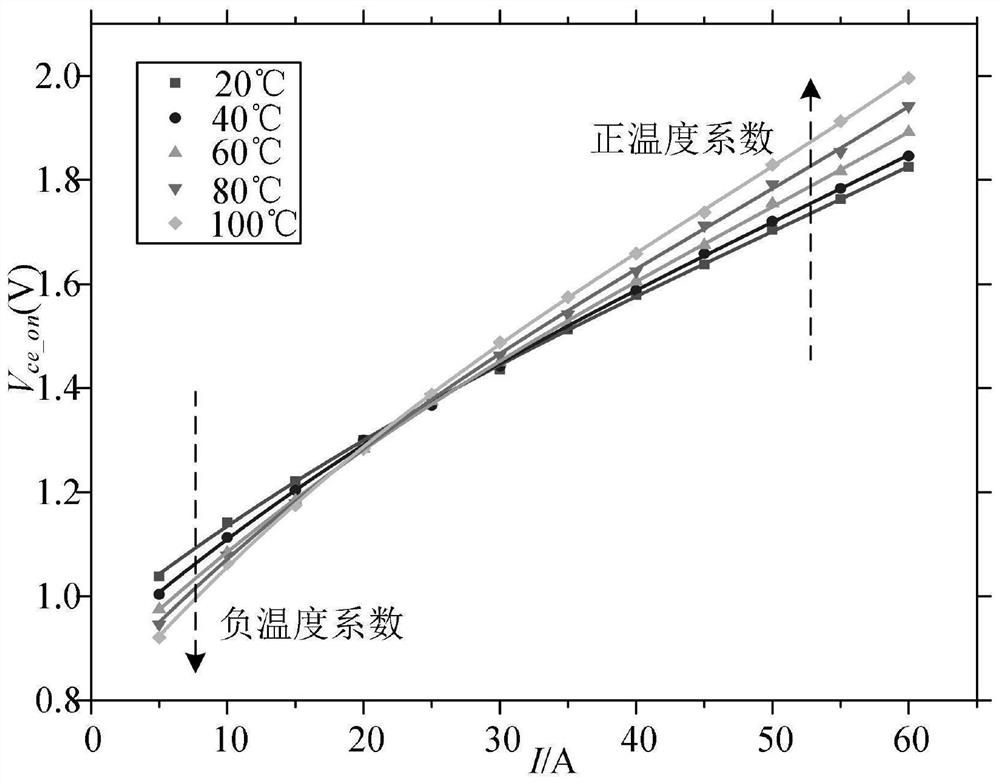

[0035] Carry out double-pulse test verification and offline correction operation for the IGBT module used in the traction rectifier. First, the on-line voltage drop monitoring circuit is connected in parallel on both sides of the collector and emitter of the upper and lower bridge arm IGBT modules, and then the IGBT modules are fixed in On constant temperature boards with different temperatures, after the junction temperature is stable, perform a double-pulse test. When the current passing through the upper bridge arm IGBT increases, record the conduction voltage drop of the upper tube through different currents at the junction temperature at this moment. The on-voltage drop and collector current data at the junction temperature are fitted, and the relationship between the junction temperature, on-voltage drop and current of the top-tube IGBT is shown in image 3 shown. When the upper tube IGBT is turned off, the clamping circuit in its conduction voltage drop measurement circui...

Embodiment 2

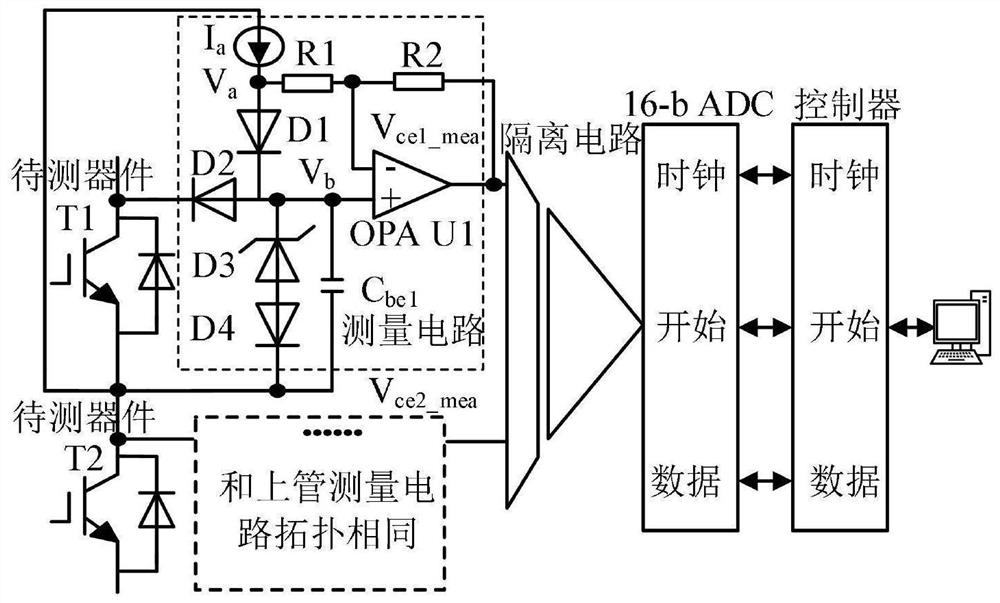

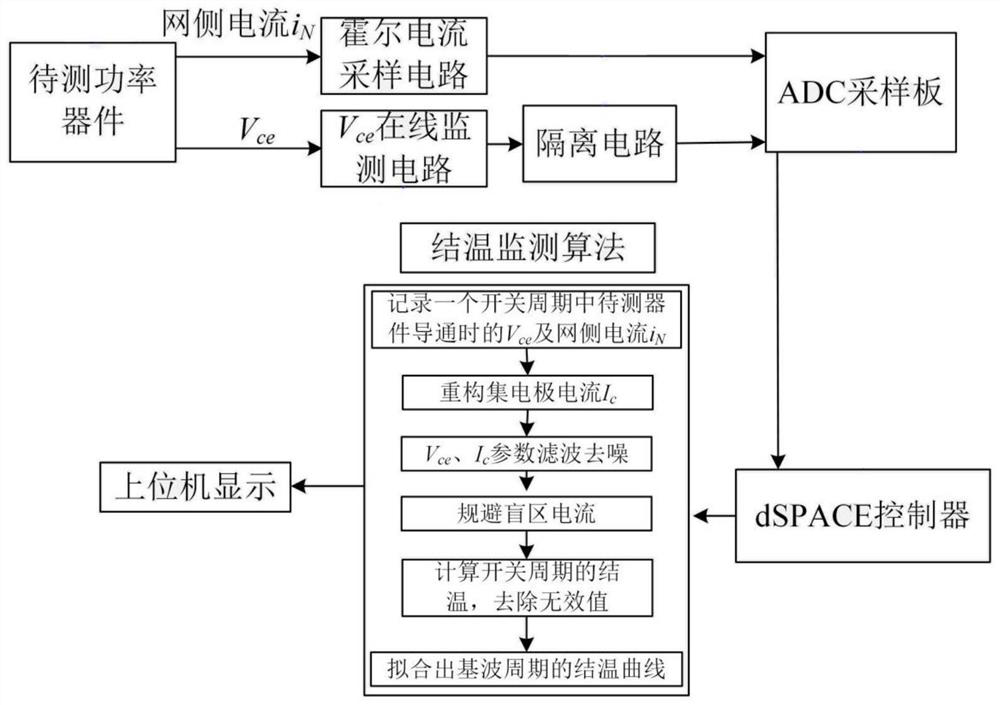

[0040] Example 2: To monitor the junction temperature of the IGBT chip in the traction rectifier, the on-line voltage drop monitoring circuit of the present invention is connected in parallel to the collector and emitter ends of the upper and lower bridge arm IGBT modules respectively. Then connect the on-line monitoring circuit of the upper and lower bridge arms to the isolation circuit, then connect the isolation circuit to the 16-bit ADC converter, and then transmit it to the DSP controller. When the output value of the measurement circuit is greater than 0V and less than the clamping voltage When the output value is less than 0V, it is the on-voltage drop value of the reverse diode chip. The grid-side current of the traction rectifier is collected by the current sampling circuit, passed through the 16-bit ADC converter, and then transmitted to the DSP controller. After processing the current signal, the current waveform passing through the IGBT chip is obtained. The juncti...

Embodiment 3

[0042] Example 3: The junction temperature monitoring was performed on the IGBT chip in the accelerated aging test platform, and the on-line voltage drop monitoring circuit of the present invention was connected in parallel to both ends of the collector and the emitter of the IGBT module to be tested. Then set V ce The output of the online monitoring circuit is passed to the controller, and the junction temperature is calculated through the offline corrected junction temperature relationship. Figure 7 The junction temperature monitoring results of this paper's measurement circuit and infrared thermometer in the accelerated aging test bench are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com