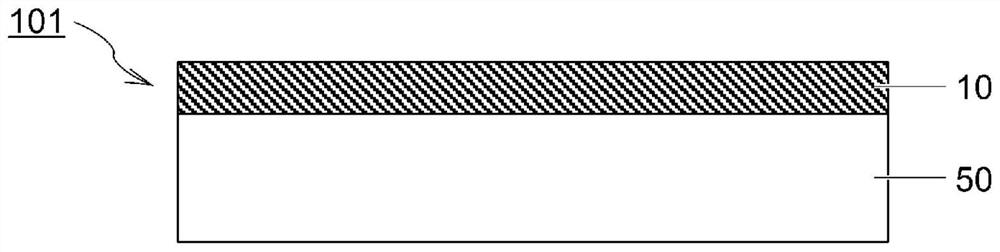

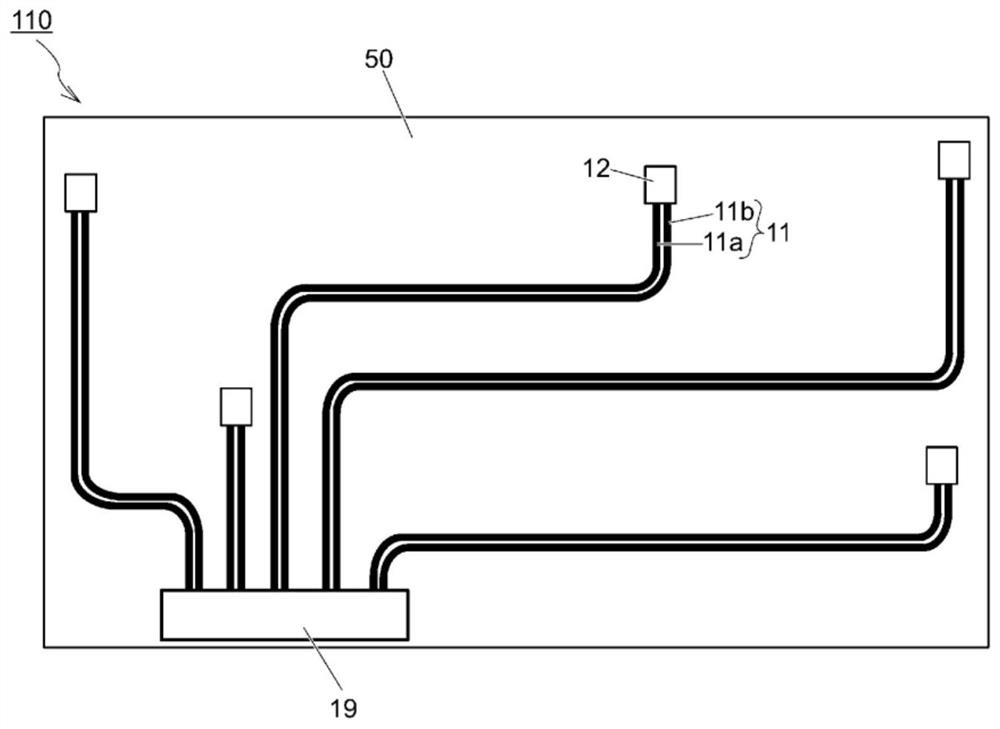

Temperature sensor film, electrically conductive film, and method for producing same

A technology of temperature sensor and conductive film, which is applied to thermometers, thermometers and instruments using electric/magnetic elements that are directly sensitive to heat, can solve the problems of complicated manufacturing process and rising cost, and achieve high temperature measurement accuracy and stability Excellent, high temperature coefficient of resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to the following examples.

[0088] [Evaluation method]

[0089]

[0090] Using a quadrupole secondary ion mass spectrometer ("PHI ADEPT-1010" manufactured by ULVAC-PHI. INC.), the primary ion species: Cs + , Acceleration energy: 2.0keV, grating area: 300μm×300μm, detection area: 100μm×100μm, through secondary ion mass spectrometry

[0091] (SIMS), and the concentration distribution (depth profile) in the depth direction from the surface of the conductive thin film (surface of the nickel layer) was measured. Set the Ni concentration to 1×10 19 atm / cm 3The above region was defined as a Ni layer, and the concentration of carbon atoms in the center in the thickness direction was defined as the carbon content of the nickel layer.

[0092]

[0093] The surface resistance was measured by the four-probe method using a resistivity mete...

Embodiment 1

[0116] Except having changed the board|substrate temperature into 0 degreeC, it carried out similarly to the comparative example 1, and produced the electroconductive thin film.

Embodiment 2

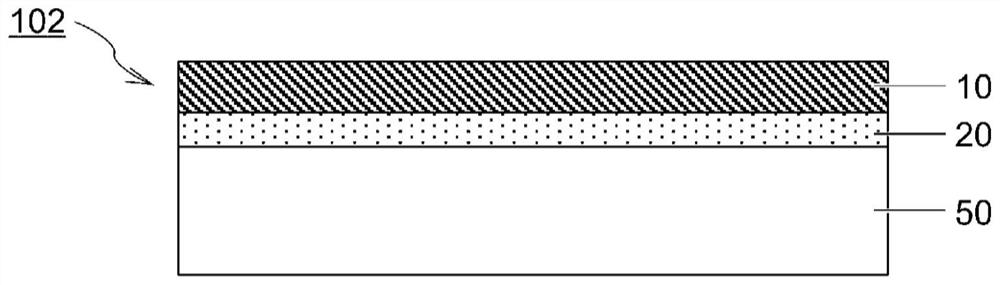

[0118] On the PET film, a silicon layer with a thickness of 5nm and a silicon oxide layer with a thickness of 10nm are sputtered into films successively as the base layer, and a Ni layer is formed on it under the same conditions as Comparative Example 1, and the PET film with Si layer (5nm), SiO 2 layer (10nm), Ni layer (70nm) conductive thin film. Si layer and SiO 2 A B-doped Si target was used for layer formation. For the Si layer, argon gas is introduced as the sputtering gas, at a substrate temperature of 150°C, a pressure of 0.3Pa, and a power density of 1.0W / cm 2 Film formation was performed by DC sputtering under certain conditions. For SiO 2 layer, in addition to argon as the sputtering gas, oxygen (O 2 / Ar=1.0), at a substrate temperature of 150°C, a pressure of 0.3Pa, and a power density of 1.8W / cm 2 Film formation was performed by DC sputtering under certain conditions. The magnetic flux density on the surface of the Si target was 100 mT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| temperature coefficient of resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com