Grape essence

A technology of grape flavor and flavor base, which can be used in food ingredients as taste improvers, food ingredients as odor improvers, dairy products, etc., can solve the problems of flavor differences, the loss of grape differential production process, and reducing the advantages of individualization. , to achieve the effect of high aroma quality and enhanced juice sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

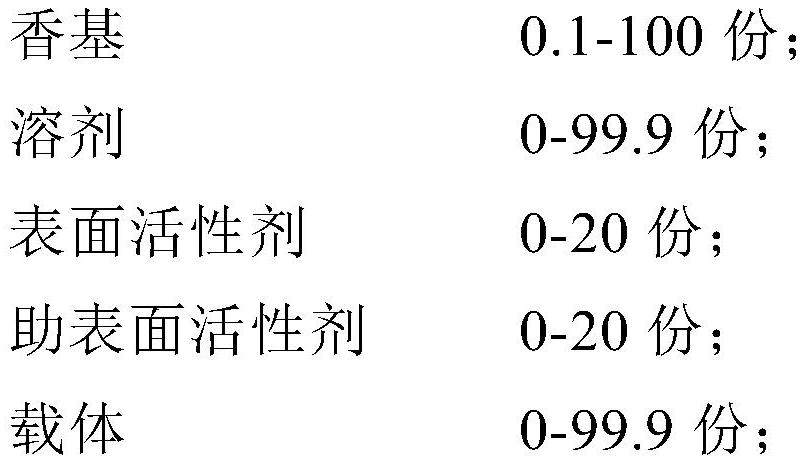

[0021] The raw materials were weighed as shown in Table 1:

[0022] Table 1

[0023]

[0024]

[0025] Stir the raw materials evenly to obtain 16.0 kg of fragrance base, add 84.0 kg of edible alcohol to the fragrance base, stir until completely dissolved and evenly, and obtain 100 kg of liquid grape essence.

[0026] Comparative example 1-1 changes the consumption of methyl anthranilate in embodiment 1 to 0.9kg, the consumption of ethyl acetoacetate is changed from 0.6kg, correspondingly changes the weight of alcohol, makes the weight sum of composition still be 100kg. The rest are equal to Example 1.

[0027] Comparative example 1-2 changes the consumption of methyl anthranilate in embodiment 1 into 0.6kg, changes N-methyl methyl anthranilate into 0.6kg, changes the weight of alcohol accordingly, makes the weight of composition and still 100kg. The rest are equal to Example 1.

[0028] Comparative example 1-3 changes the consumption of ethyl maltol into 3.5kg among ...

Embodiment 2

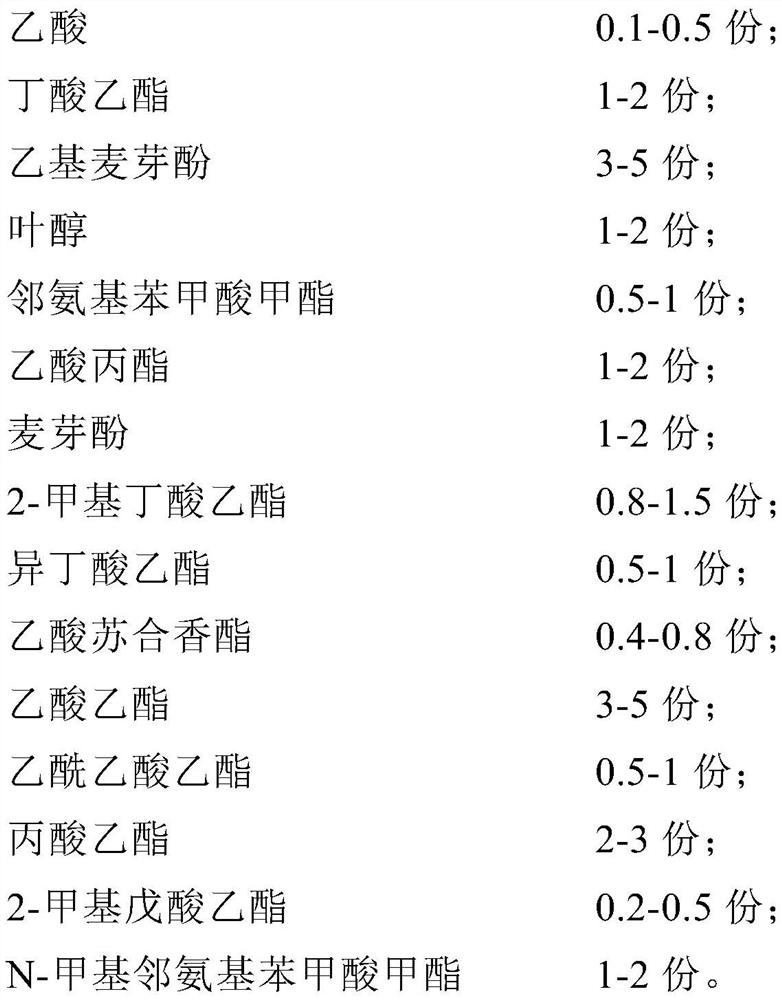

[0038] The raw materials are weighed as shown in Table 3:

[0039] table 3

[0040] Acetic acid 0.1kg ethyl butyrate 1kg ethyl maltol 3kg Leaf alcohol 1kg Methyl anthranilate 0.5kg Propyl acetate 1kg maltol 1kg Ethyl 2-methylbutyrate 0.8kg ethyl isobutyrate 1kg styroyl acetate 0.4kg ethyl acetate 3kg ethyl acetoacetate 1kg ethyl propionate 2kg Ethyl 2-methylpentanoate 0.2kg Methyl N-methylanthranilate 1kg

[0041] Stir the raw materials evenly to obtain 17.0kg of fragrance base, then add 10kg of silicon dioxide to the fragrance base and mix evenly, and finally add 73kg of maltodextrin and mix until uniform to obtain 100kg of powdered grape essence.

[0042] In Comparative Example 2-1, in Example 2, maltodextrin was replaced by cornstarch, and the rest was the same as Example 2.

[0043] Comparative Example 2-2 In Example 2, the amount of silicon dioxide was change...

Embodiment 3

[0052] The raw materials are weighed as shown in Table 5:

[0053] table 5

[0054]

[0055]

[0056] Stir the raw materials evenly to obtain 24.0kg of fragrance base, then add 1kg of glycerol monostearate and 0.5kg of sucrose ester to the fragrance base and stir until completely dissolved, then slowly add to 74.5kg of 20% gum arabic aqueous solution , after 10 minutes of high shear, homogenize to obtain 100kg of emulsified grape essence.

[0057] In Comparative Example 3-1, the amount of glyceryl monostearate in Example 3 was changed to 0.9 kg, and the weight of the aqueous solution was changed accordingly, so that the sum of the weights of the ingredients was still 100 kg. The rest are equal to Example 3.

[0058]In Comparative Example 3-2, in Example 3, glyceryl monostearate was replaced by lecithin, and 0.5kg glycerol rosin was added, and the weight of the aqueous solution was changed accordingly, so that the sum of the weights of the ingredients was still 100kg. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com