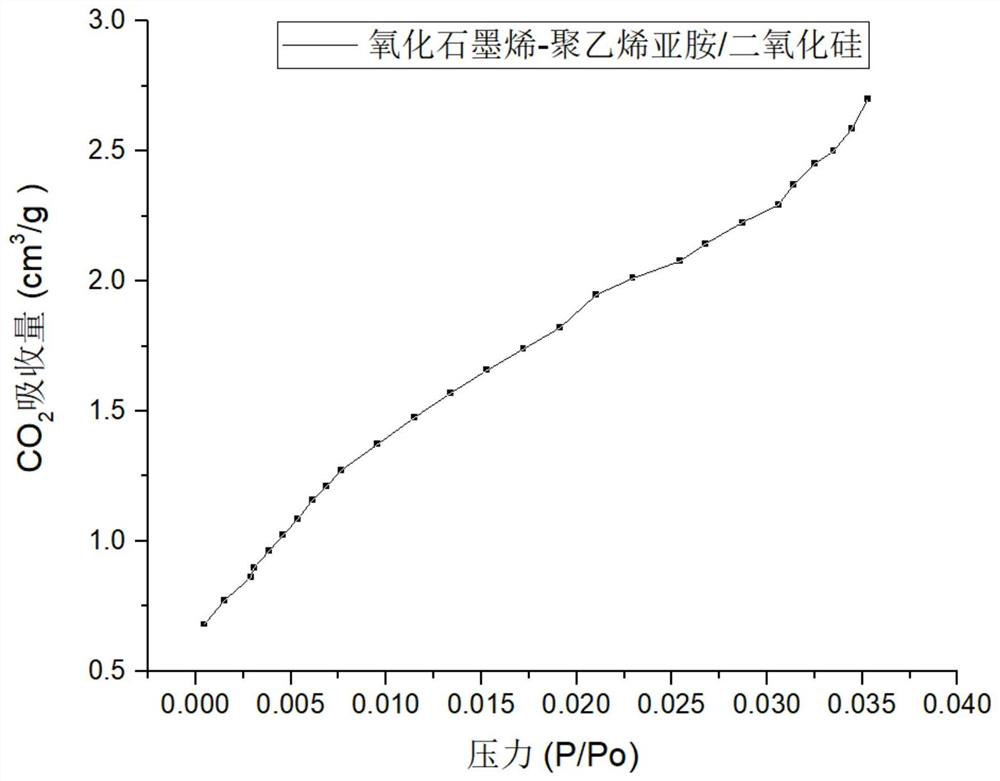

Preparation method of graphene oxide-polyethyleneimine/silicon dioxide composite aerogel

A technology of polyethyleneimine and composite airgel, which is applied in the fields of alkali metal oxides/hydroxides, chemical instruments and methods, and separation methods, and can solve the problems of difficulty in maintaining a complete structure, low carbon dioxide adsorption capacity, and poor mechanical properties and other issues, to achieve the effects of easy access, improved adsorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

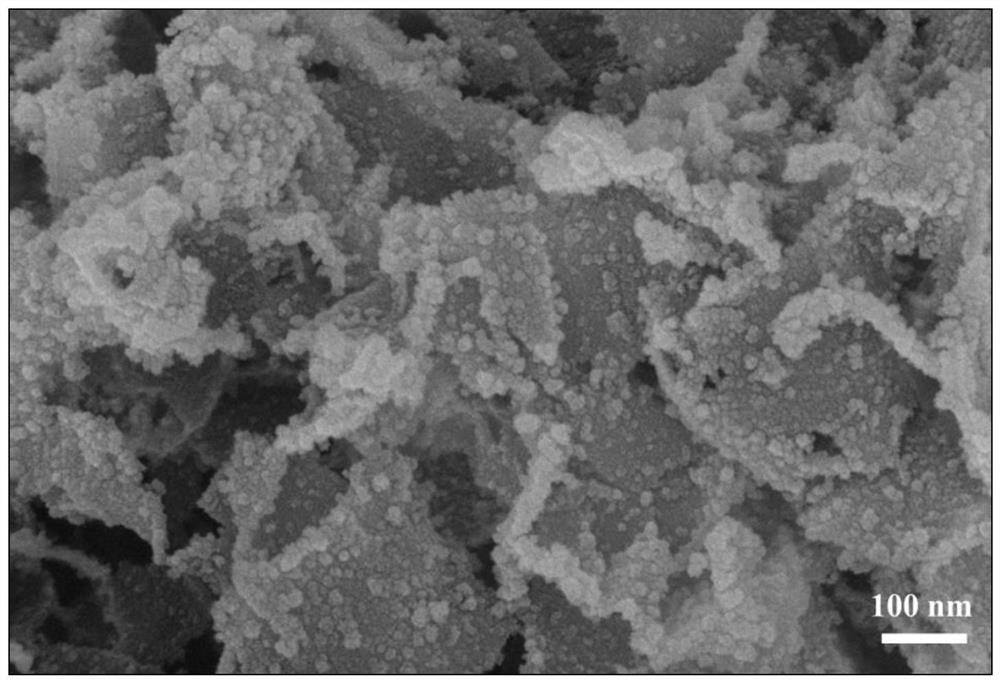

[0029] This embodiment includes the following steps:

[0030] Step 1. Peel off the graphene oxide aqueous solution with a concentration of 2 mg / mL in an ultrasonic water bath for 1 h to obtain a uniformly dispersed graphene oxide dispersion, and then adjust the pH value to 8.0 with a sodium hydroxide aqueous solution with a concentration of 4 mg / mL;

[0031] Step 2. Mix the graphene oxide dispersion after adjusting the pH value in step 1 with the polyethyleneimine aqueous solution with a concentration of 10 mg / mL according to a volume ratio of 1:1 to prepare a graphene oxide-polyethyleneimine mixed solution , and immerse and condense for 24 hours at a low temperature of 0°C;

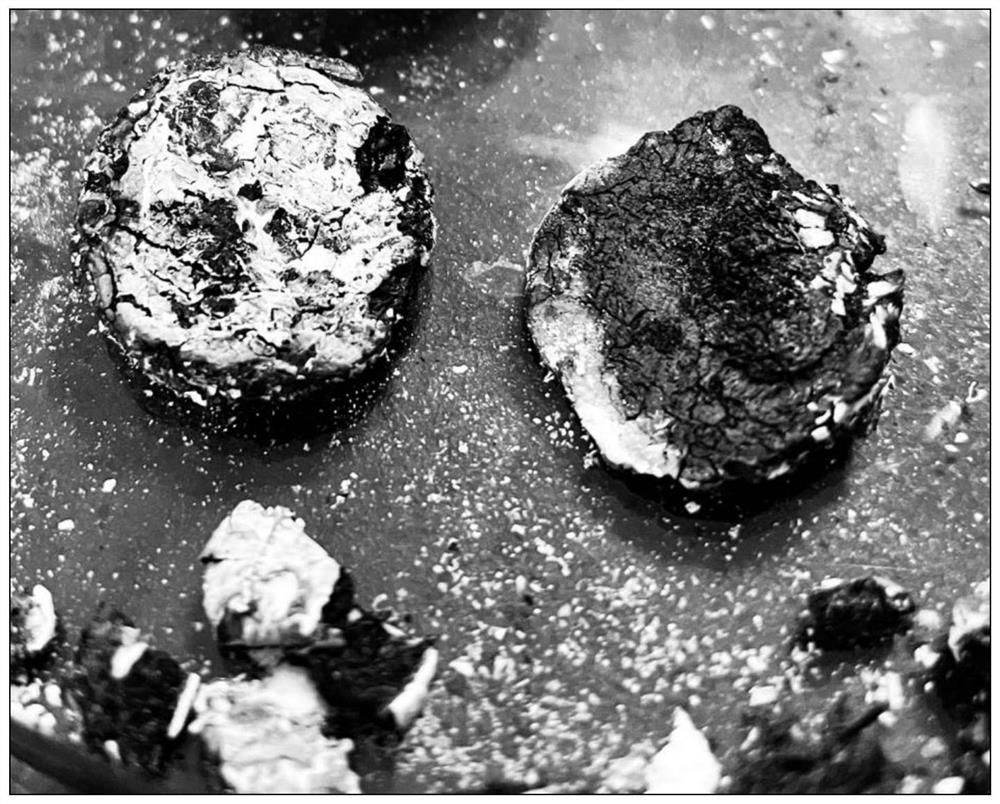

[0032] Step 3: Pour the graphene oxide-polyethyleneimine mixture that has been soaked and condensed in step 2 into the mold, cover it with a plastic wrap and make small holes in the plastic wrap, keep it warm at 20°C for 24 hours, and then Remove the membrane and soak in deionized water for 1 hour to ob...

Embodiment 2

[0039] The difference between this embodiment and Example 1 is that: the graphene oxide aqueous solution with a concentration of 5 mg / mL is selected in step one; the polyethyleneimine aqueous solution with a concentration of 20 mg / mL is selected in step two; Keep the temperature and keep it for 18 hours; in step 4, prepare the silicon dioxide precursor solution with the silicon water ratio of 1:5 between the precursor and water, control the silicon content at 1.2mol / L, and put the hydrogel at a low temperature of 0°C Soak and coagulate for 18 hours under the same conditions.

Embodiment 3

[0041] The difference between this embodiment and Example 1 is that in step 1, the graphene oxide aqueous solution with a concentration of 10 mg / mL is selected; in step 2, a polyethyleneimine aqueous solution with a concentration of 30 mg / mL is selected; Keep the temperature and keep it for 12 hours; in step 4, the precursor and water are prepared according to the silicon-water ratio of 1:7 to prepare the silicon dioxide precursor solution, and the silicon content is controlled at 1.6mol / L. Soak and coagulate for 12 hours under the same conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com