Terahertz modulator based on graphene/boron nitride heterostructure and preparation method thereof

A heterostructure, boron nitride technology, applied in the field of terahertz wave applications, can solve the problems of influence, small optical modulation depth, low efficiency, etc., achieve strong modulation capability, improve optical modulation depth and speed, and increase carriers. The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

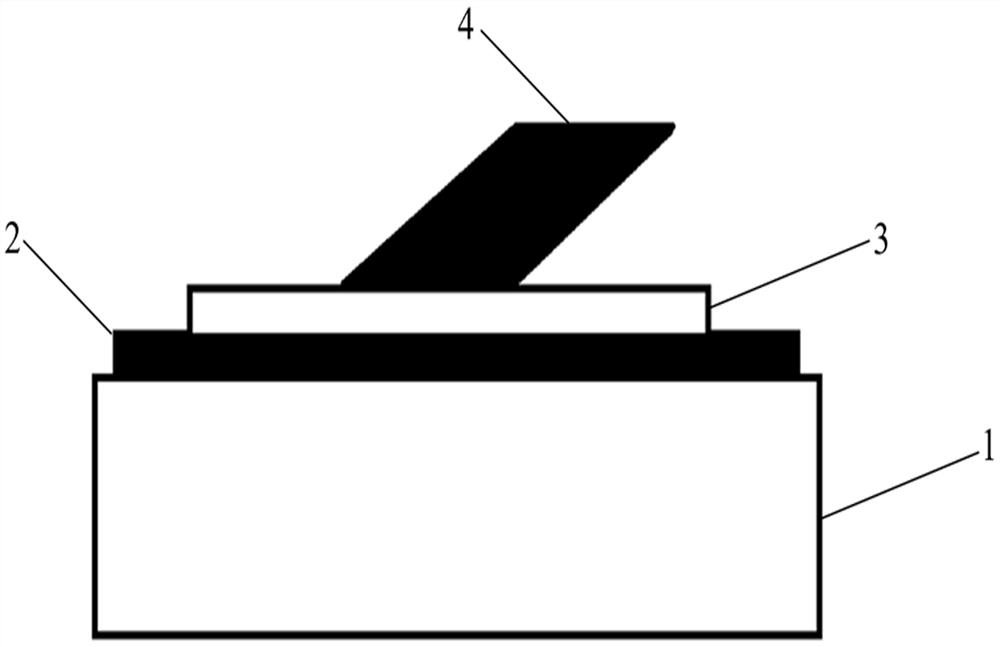

[0019] An embodiment of the present invention provides an optically controlled terahertz wave modulator based on a graphene / boron nitride heterostructure, figure 1 A schematic structural diagram of an optically controlled terahertz wave modulator based on a graphene / boron nitride heterostructure according to an embodiment of the present invention is shown, including a p-type silicon substrate 1, a boron nitride thin film 2, Graphene film 3 and infrared laser beam 4;

[0020] During the modulation process, the terahertz wave is incident vertically from one side of the graphene film 3, and the detector is received on the other side of the P-type silicon substrate 1; during optical modulation, the infrared laser beam 4 is incident at a certain angle (45° angle) to the graphene film side to achieve optical modulation. Due to its large band gap and small thickness, the introduction of boron nitride film will further effectively separate the photogenerated electrons and holes, prev...

Embodiment approach

[0024] As a specific implementation manner, the resistivity of the P-type silicon substrate 1 is 10-30 Ω•cm, and the thickness of the P-type silicon substrate is 400-600 μm.

[0025] As a specific implementation manner, the resistivity of the graphene film 3 is 100-3000Ω·cm.

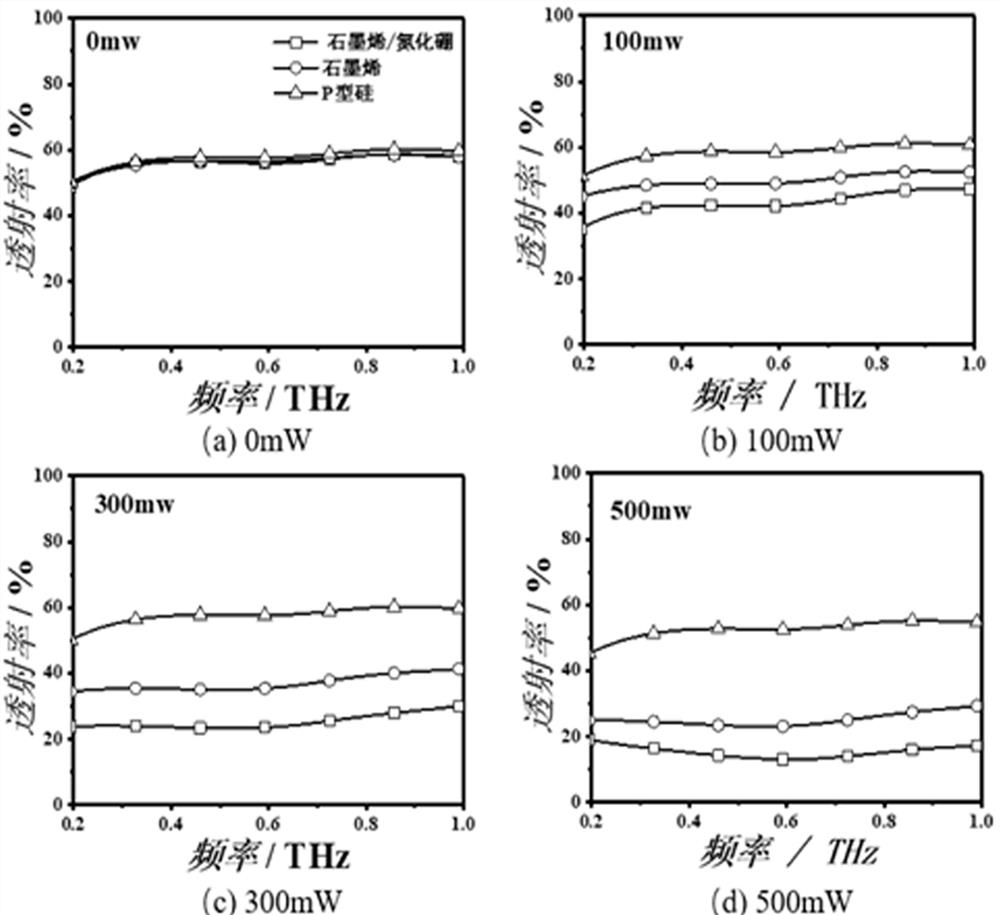

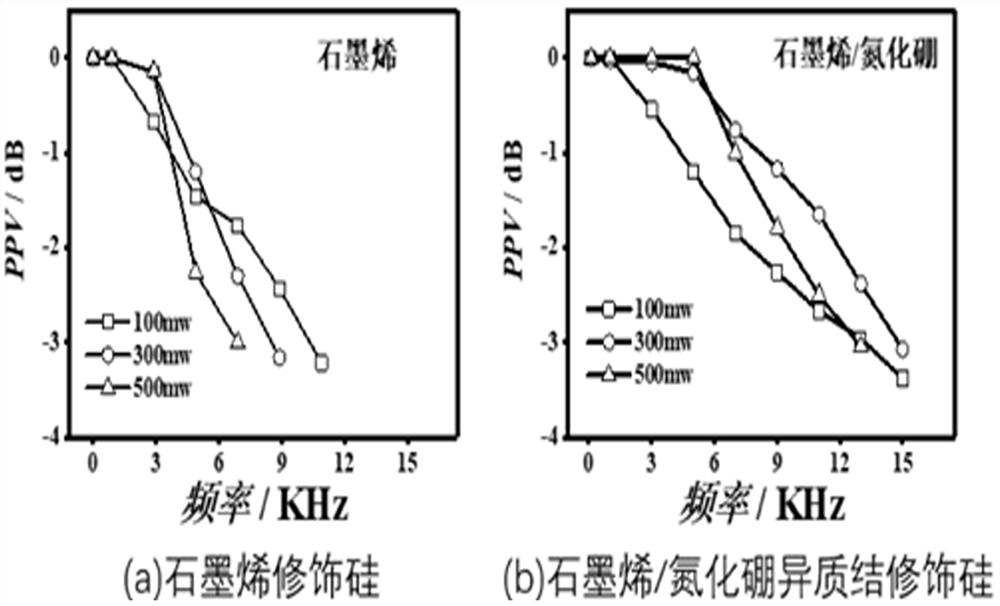

[0026] A terahertz modulator based on a graphene / boron nitride heterostructure provided by the present invention, the terahertz wave modulator includes a p-type silicon substrate, a boron nitride film, and a graphene film arranged in sequence from bottom to top As well as infrared laser beams, compared with conventional graphene film-modified terahertz modulators, boron nitride films can greatly increase the carrier mobility of graphene films, graphene / boron nitride heterostructures and single-layer graphite Compared with the graphene-modified silicon structure, the carrier mobility of the graphene-modified silicon is much higher. Under the irradiation of the same power laser, the internal carrier mobili...

Embodiment 2

[0028] An embodiment of the present invention provides a method for preparing an optically controlled terahertz wave modulator based on a graphene / boron nitride heterostructure. The terahertz wave modulator is prepared by the following steps:

[0029] Step 1. Cut the single-oxide layer p-type silicon wafer (100) with a front oxide layer thickness of 100nm and a resistivity between 10-30 Ω·cm into square pieces of 10mm×10mm, and use acetone, alcohol, and deionized The water is cleaned in ultrasonic, and dried with nitrogen gas to obtain a clean silicon wafer;

[0030] Step 2, transfer boron nitride film:

[0031] Cut the copper substrate with boron nitride film obtained by CVD into a size of 9mm×9mm, spin-coat a layer of PMMA on the side where the boron nitride film grows, and then put 1mol / L FeCl 3 The copper substrate was corroded in the solution. After standing for 3 hours, a layer of transparent film (PMMA) floating on the surface of the solution was observed, which proved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com