Low-cobalt high-power ternary positive electrode material and preparation method thereof

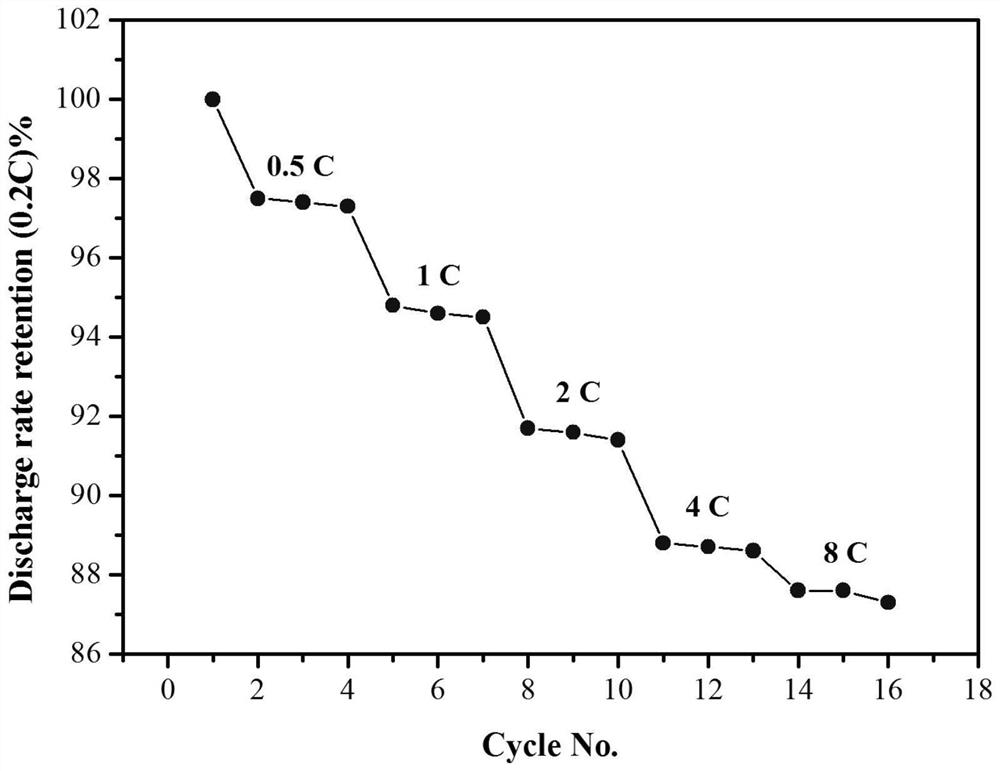

A positive electrode material and high-power technology, applied in chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of high raw material prices, large negative impact on power performance, high cobalt content, etc., to reduce cobalt content and enhance the interface Stability, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

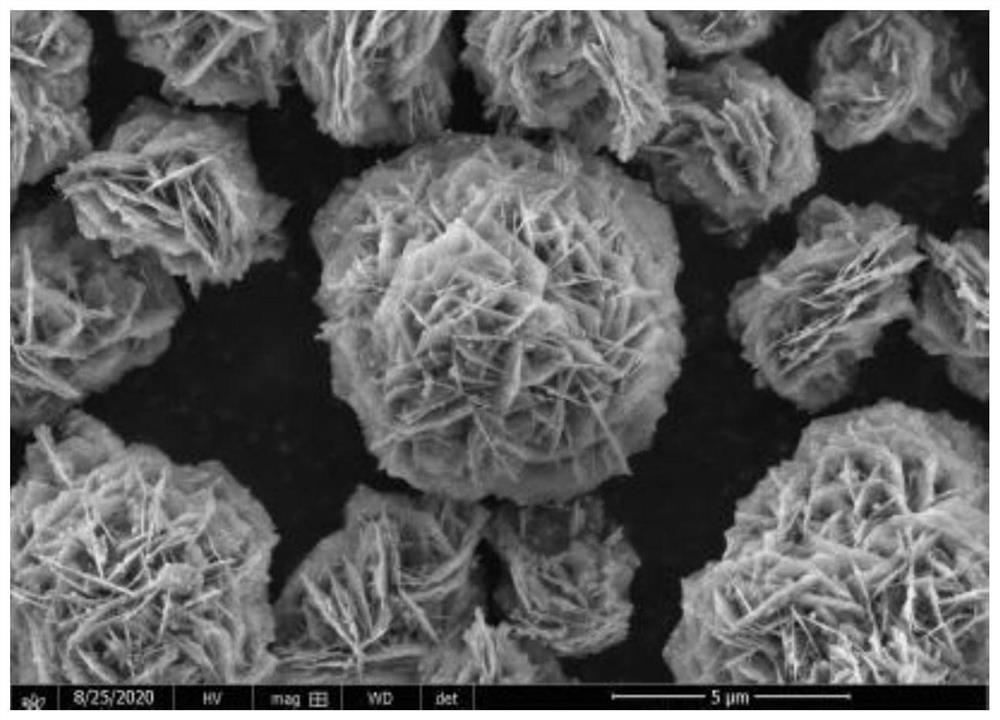

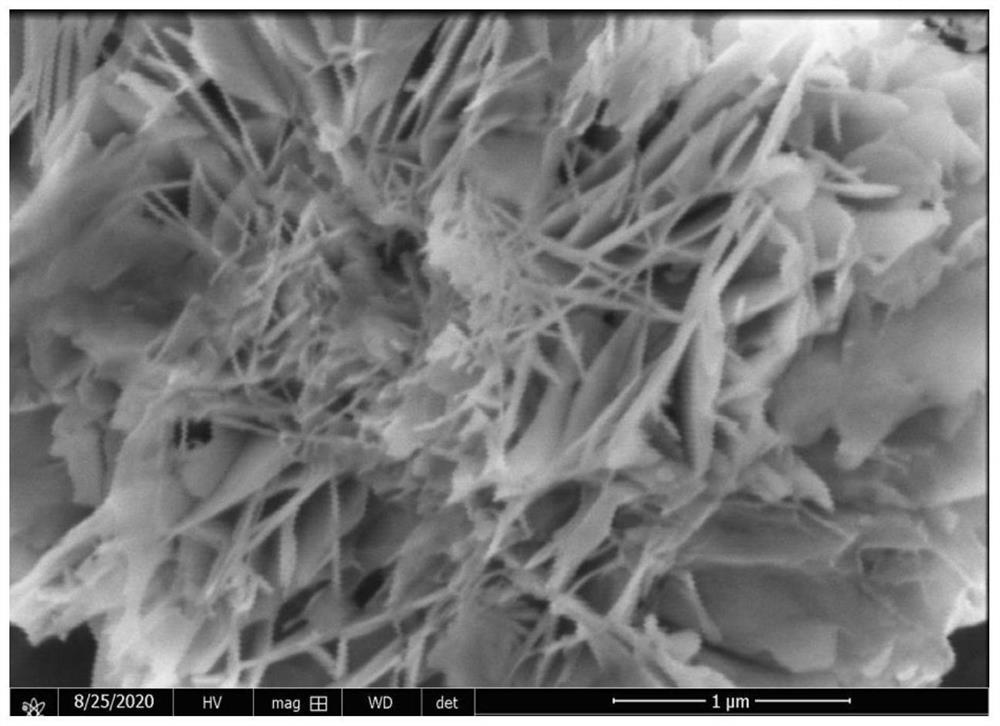

[0023] The preparation method of low-cobalt high-power type ternary cathode material comprises the following steps:

[0024] (1) The molar ratio of preparing nickel ion and manganese ion is (1~99):(1~99) nickel and manganese mixed binary solution, the concentration sum of nickel ion and manganese ion in nickel and manganese mixed binary solution 0.5mol / L~2.5mol / L; prepare 0.5mol / L~2.5mol / L cobalt solution; industrial liquid alkali with a concentration of 20%~32% as the first precipitant solution; prepare 0.5mol / L~2mol / L of ammonium bicarbonate or sodium carbonate solution as the second precipitant solution; prepare ammonia water with a concentration of 10% to 20% as the complexing agent solution.

[0025] (2) Feed nitrogen into the reaction kettle with the bottom liquid as a protective gas, and start stirring the reaction kettle; the flow rate of nitrogen gas is 0.5m 3 / h~3m 3 / h; the amount of bottom liquid added is 1 / 2~4 / 5 of the volume of the reactor; the bottom liquid i...

Embodiment 1

[0030] Prepare a mixed binary solution of nickel and manganese with a molar ratio of nickel ions and manganese ions of 63:37. The sum of the concentrations of nickel ions and manganese ions in the mixed binary solution of nickel and manganese is 0.5mol / L; prepare 0.5mol / L the cobalt solution; the concentration is 20% industrial liquid alkali as the first precipitant solution; the preparation of 0.5mol / L ammonium bicarbonate is as the second precipitant solution; the preparation concentration is 10% ammonia water as the complexing agent solution.

[0031] Feed nitrogen into the reaction kettle with bottom liquid as a protective gas, start stirring the reaction kettle, the stirring speed is 500rpm; the flow rate of nitrogen gas is 3m 3 / h; the amount of bottom liquid added is 1 / 2 of the volume of the reactor; the bottom liquid includes ammonia water and industrial liquid caustic soda, the ammonia concentration in the bottom liquid is 10g / L, the pH of the bottom liquid is 12.2 to ...

Embodiment 2

[0036] Prepare a mixed binary solution of nickel and manganese with a molar ratio of nickel ions and manganese ions of 87:13. The sum of the concentrations of nickel ions and manganese ions in the mixed binary solution of nickel and manganese is 1.5mol / L; prepare 1.5mol / L the cobalt solution; the concentration is 32% of the industrial liquid alkali as the first precipitant solution; the preparation of 1.5mol / L ammonium bicarbonate as the second precipitant solution; the preparation concentration of 15% ammonia as the complexing agent solution.

[0037] Introduce nitrogen into the reaction kettle with bottom liquid as protective gas, start stirring the reaction kettle, the stirring speed is 600rpm; the flow rate of nitrogen gas is 1.5m 3 / h; the addition of the bottom liquid is 2 / 3 of the volume of the reactor; the bottom liquid includes ammonia water and industrial liquid alkali, the ammonia concentration in the bottom liquid is 5g / L, the pH of the bottom liquid is 12.0-12.2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com