Micromotor carrier and preparation method and application thereof

A micro-motor and carrier technology, applied in the field of micro-motors, can solve problems such as weak ability to cross cell and tissue barriers, and achieve the effect of improving delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a kind of unloaded micromotor carrier (microtablet form), and its preparation method comprises the following steps:

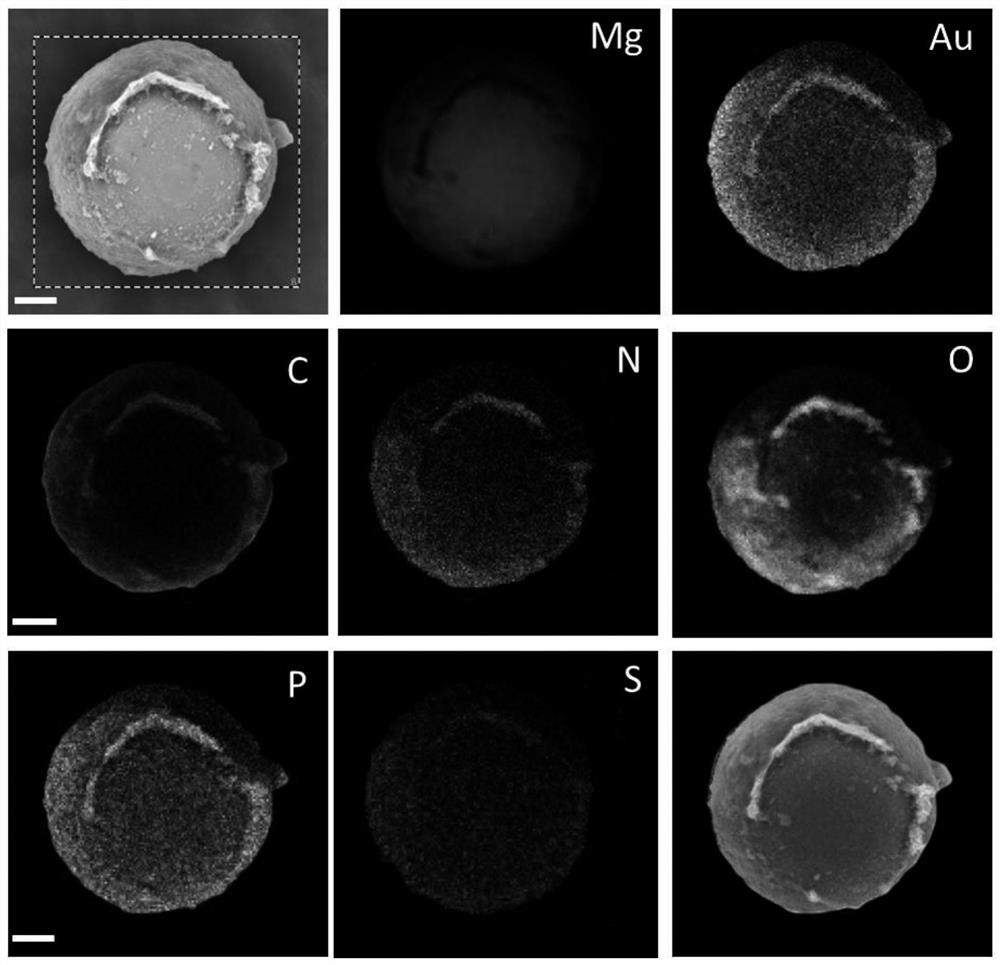

[0043] (1) Screen magnesium particles to obtain magnesium powder particles with a particle size of 9-15 μm; use magnesium particles as the core, and use ion sputtering (current 25-35mA, processing time 2-4min) to prepare coated Au the micro motor;

[0044](2) Using spin coating technology, the chitosan solution is coated on the surface of the micromotor, and the thickness of the chitosan coating is 1-3 μm; then use a 5-fold diluted phospholipid solution (cholesterol and lecithin 1:1 mixed) to The micromotor is coated with the spin coating method, and the thickness of the phospholipid film is about 1-3 μm. After tableting, the micromotor is coated with esterified starch (DS value 1.5-2.5) to obtain a non-drug-loaded micromotor carrier (such as figure 1 Shown), its particle size is 15-20μm.

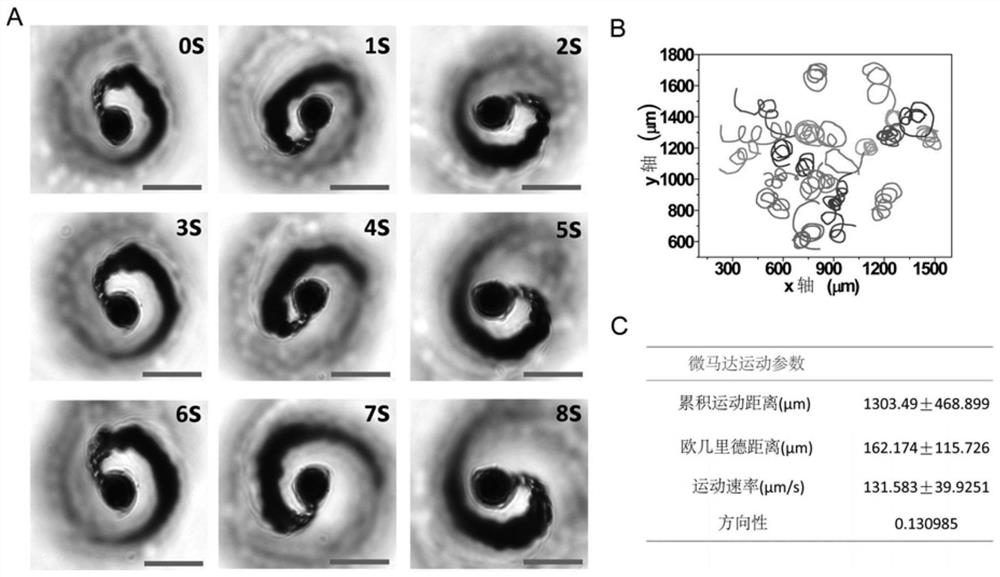

[0045] like figure 2 As sho...

Embodiment 2

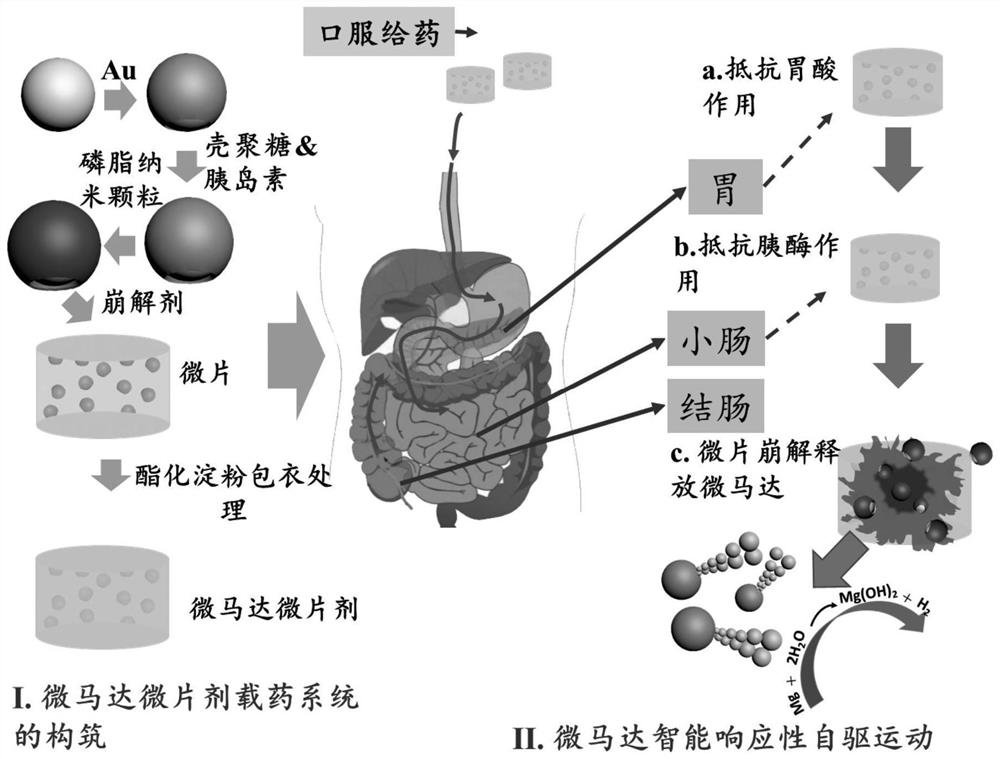

[0047] This embodiment provides a micromotor carrier (microtablet form) loaded with insulin, according to image 3 The process flow shown and the schematic diagram of insulin oral delivery, its preparation method comprises the following steps:

[0048] (1) Screen magnesium particles to obtain magnesium powder particles with a particle size of 9-15 μm; use magnesium particles as the core, and use ion sputtering (current 25-35mA, processing time 2-4min) to prepare coated Au the micro motor;

[0049] (2) adopt spin-coating technology, the chitosan solution (the concentration of insulin in chitosan solution is 1wt%) that will be loaded with insulin is coated on micromotor surface, and the chitosan coating thickness is at 1-3 μ m; Use a 5-fold diluted phospholipid solution (cholesterol and lecithin 1:1 mixture) to coat the micromotor by spin coating. The thickness of the phospholipid film is about 1-3 μm. -2.5) Coating the micromotors to obtain insulin-loaded micromotor carriers ...

Embodiment 3

[0052] This embodiment provides a micromotor carrier (microtablet form) loaded with insulin, according to image 3 The process flow shown and the schematic diagram of insulin oral delivery, its preparation method comprises the following steps:

[0053] (1) Screen magnesium particles to obtain magnesium powder particles with a particle size of 20-28 μm; use magnesium particles as the core, and use ion sputtering (current 25-35mA, processing time 2-4min) to prepare coated Au the micro motor;

[0054] (2) adopt spin-coating technology, the chitosan solution (the concentration of insulin in chitosan solution is 1wt%) that will be loaded with insulin is coated on micromotor surface, and the chitosan coating thickness is at 1-3 μ m; Use a 5-fold diluted phospholipid solution (cholesterol and lecithin 1:1 mixture) to coat the micromotor by spin coating. The thickness of the phospholipid film is about 1-3 μm. -2.5) Coating the micromotor to prepare a micromotor carrier loaded with i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com