Laser ablation processing device and method for surface microstructure of curved-surface workpiece

A surface workpiece, laser ablation technology, used in auxiliary devices, laser welding equipment, metal processing equipment and other directions, can solve the problems of not using laser processing, affecting the quality of ablation, marking depth, etc., to avoid discontinuous processing surfaces , Good controllability, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, laser ablation processing of a curved micro-texture on a stainless steel ball is taken as an example.

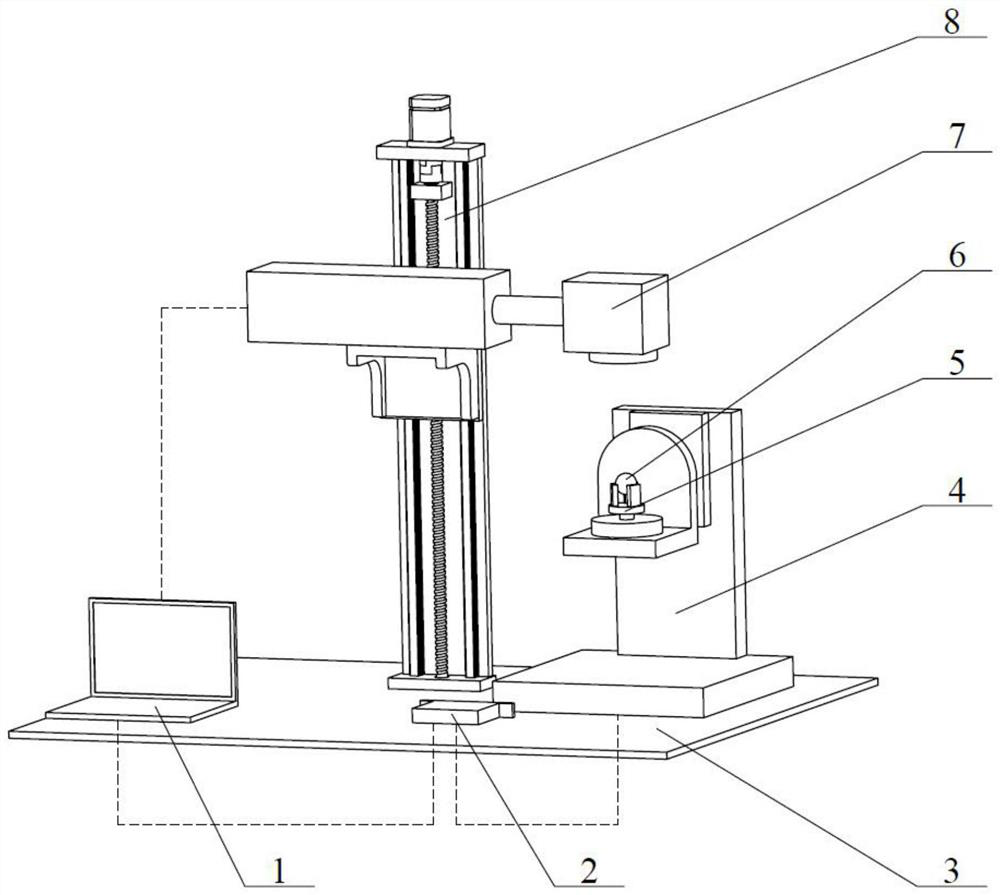

[0033] The laser ablation processing device for micro-texture on the surface of a curved workpiece provided in this embodiment includes: a fixed seat 3, a linear module 8, a laser 7 installed on the linear module, a five-axis linkage mechanical motion platform 4, and a multi-axis motion control Machine 2 and Computer 1.

[0034] The fixing seat 3 is used for fixing the support;

[0035] The linear module 8 and the laser 7 installed on the linear module 8 are fixedly connected to the fixing seat 3; the linear module 8 drives the laser 7 to move up and down along the Z-axis direction;

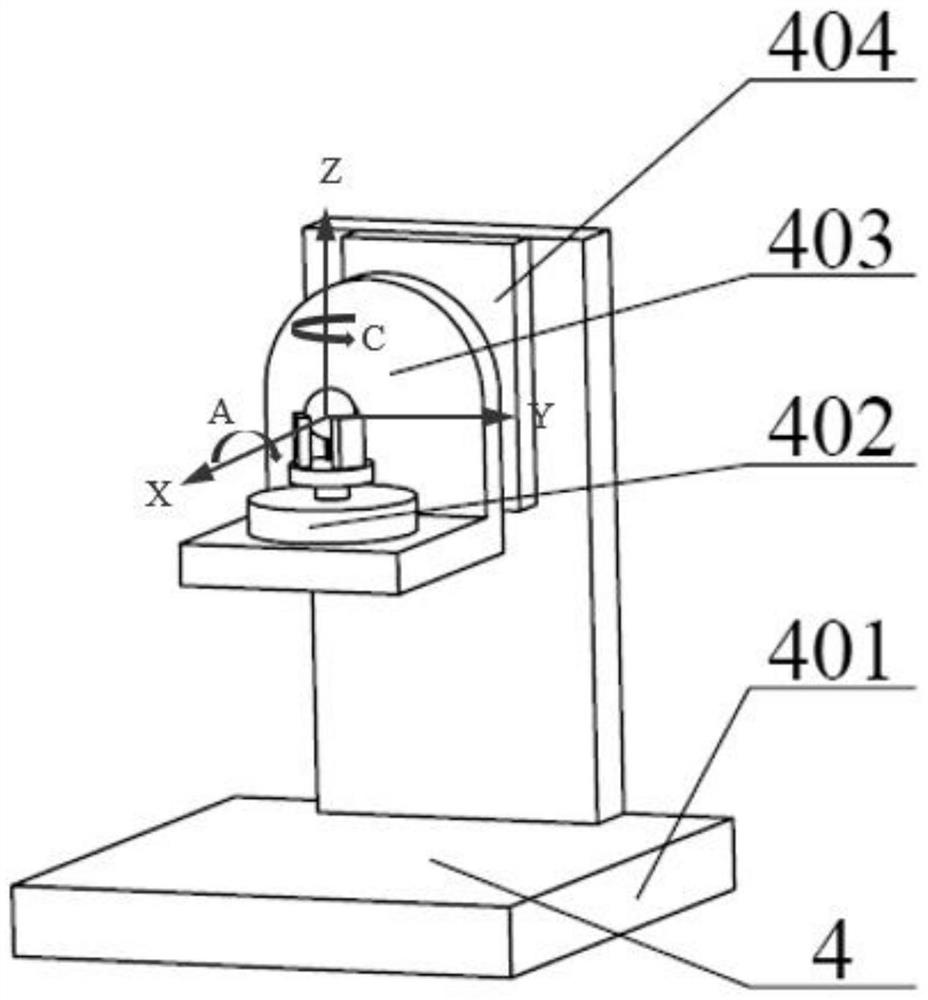

[0036] The five-axis linkage mechanical movement platform 4 is set on the fixed seat 3, and the five-axis linkage mechanical movement platform 4 is equipped with a clamp 5, which is used to fix the curved surface parts to be processed; the five-axis linkage mechanica...

Embodiment 2

[0049] This embodiment is a processing method of a micro-texture laser ablation processing device on the surface of a curved workpiece provided in Embodiment 1. The specific steps are as follows:

[0050] S10, using the computer 1 to complete the setting of the processing parameters required by the multi-axis motion controller 2 and the laser 7, including parameters such as laser power, laser frequency, and movement speed of each axis of the five-axis linkage mechanical motion platform.

[0051] S20, focusing; adjust the initial position of the sliding table in the linear module 8, drive the laser 7 to move up and down along the Z-axis direction; turn on the laser 7 to emit laser light, so that the focused spot of the laser beam is positioned on the surface of the stainless steel ball 6.

[0052] S30, using CAM software to generate NC codes.

[0053] Among them, the method of using CAM software to generate NC codes is: project the arc length of the two-dimensional figure to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com