PU transparent primer as well as preparation method and application thereof

A technology of transparent primer and clean-odor alkyd resin, applied in the field of coatings, can solve problems such as odorous luster and unsatisfactory use effect, and achieve the effect of not easy to change color, increase product added value, and good filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

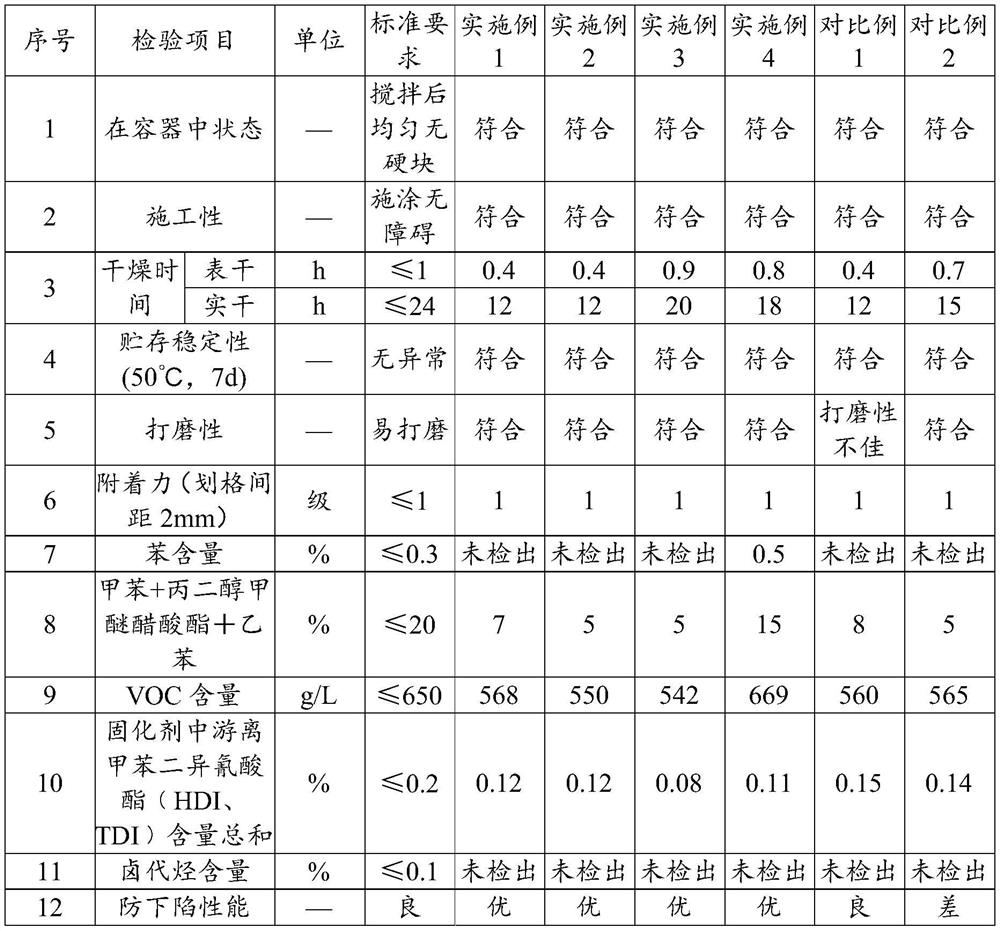

Examples

Embodiment 1

[0040] This embodiment prepares a kind of PU transparent primer, and this transparent primer is made up of 100 parts by weight of main agent, 40 parts by weight of curing agent and 80 parts by weight of diluent.

[0041] The main agent is made of the following components in weight percentage: 77.8% net taste alkyd resin, 0.3% dispersant, 0.3% defoamer, 3% fatty acid zinc powder, 5% granule powder, 0.1% leveling agent, 3% Anti-settling semi-finished products, 3% VAGH liquid semi-finished products, butyl acetate (balance).

[0042] The anti-settling semi-finished product is made of the following ingredients in percentage by weight: 50% clean alkyd resin, 30% butyl acetate, 5% bentonite and 15% polyamide wax slurry.

[0043] The VAGH liquid semi-finished product is made of the following components in weight percent: 40% VAGH, 20% methyl isobutyl ketone, 20% propylene glycol methyl ether acetate, and 20% butyl acetate.

[0044] The curing agent is made of the following components...

Embodiment 2

[0048] This embodiment prepares a kind of PU transparent primer, and this transparent primer is made up of 100 parts by weight of the main agent, 50 parts by weight of curing agent and 80 parts by weight of diluent.

[0049] The main agent is made of the following components in weight percentage: 68% net taste alkyd resin, 1% dispersant, 1% defoamer, 5% fatty acid zinc powder, 7% granule powder, 0.5% leveling agent, 5% Anti-settling semi-finished products, 5% VAGH liquid semi-finished products, butyl acetate (balance).

[0050] The anti-settling semi-finished product is made of the following ingredients in percentage by weight: 45% net odor alkyd resin, 25% butyl acetate, 8% bentonite and 22% polyamide wax slurry.

[0051] The VAGH liquid semi-finished product is made of the following components in weight percent: 40% VAGH, 20% methyl isobutyl ketone, 20% propylene glycol methyl ether acetate, and 20% butyl acetate.

[0052] The curing agent is made of the following component...

Embodiment 3

[0056] This embodiment prepares a kind of PU transparent primer, and this transparent primer is made up of 100 parts by weight of the main agent, 30 parts by weight of curing agent and 100 parts by weight of diluent.

[0057] The main agent is made of the following components in weight percentage: 68% net taste alkyd resin, 1% dispersant, 1% defoamer, 5% fatty acid zinc powder, 7% granule powder, 0.5% leveling agent, 5% Anti-settling semi-finished products, 5% VAGH liquid semi-finished products, butyl acetate (balance).

[0058] The anti-settling semi-finished product is made of the following ingredients in percentage by weight: 45% net odor alkyd resin, 25% butyl acetate, 8% bentonite and 22% polyamide wax slurry.

[0059] The VAGH liquid semi-finished product is made of the following components in weight percent: 40% VAGH, 20% methyl isobutyl ketone, 20% propylene glycol methyl ether acetate, and 20% butyl acetate.

[0060] The curing agent is made of the following componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com