Method for improving coercive force of neodymium-iron-boron magnet through efficient diffusion

A technology of NdFeB and coercive force, which is applied in the field of NdFeB magnet preparation, can solve the problems of waste of heavy rare earth elements, large amount of diffusing agent, over-strengthening of magnets, etc., so as to save usage, improve coercive force, and overall The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

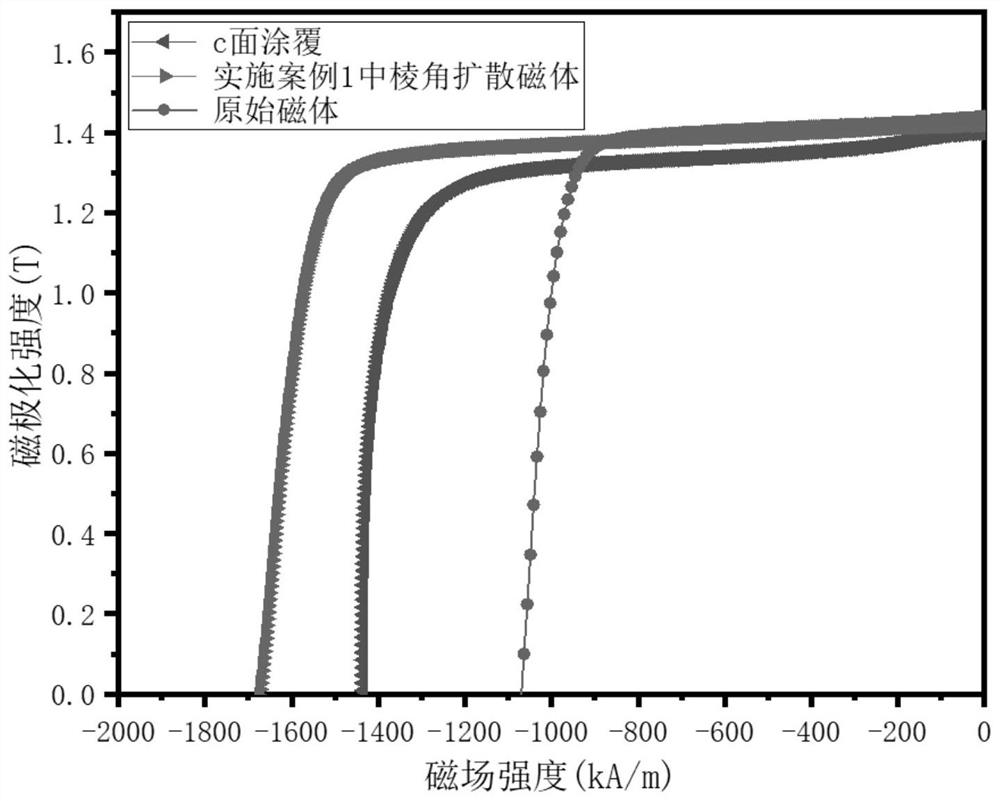

[0046] In this example, high coercive force NdFeB magnets are prepared by Pr-Tb-Al-Cu diffusion:

[0047] (1) Preparation of heavy rare earth-containing Pr by arc melting 42.26 Tb 47.67 Al 4.63 Cu 5.44 (wt%) alloy ingot.

[0048] (2) Remelting and spray-casting the alloy ingots obtained in step (1) respectively to obtain corresponding alloy strips.

[0049] (3) Coarsely crushing the alloy strip obtained in step (2) to obtain powder passing through a 60-mesh sieve.

[0050] (4) Mix the alloy powder obtained in step (3) with an organic binder (PVA glue) to obtain a diffusing agent.

[0051] (5) Use a 52M sintered NdFeB magnet as the diffusion substrate, cut into a cuboid sample by wire cutting, the size is 7×7×12mm, and the 12mm thickness direction is the easy axis (c axis) direction. After polishing it to a mirror surface, it was ultrasonically cleaned in acetone and absolute ethanol for 15 min.

[0052] (6) Apply the diffusing agent obtained in step (4) to the edge of t...

Embodiment 2

[0056] In this example, high coercive force NdFeB magnets are prepared by Tb-Al-Cu diffusion:

[0057] (1) Preparation of heavy rare earth-containing Tb by arc melting 90.45 Al 4.39 Cu 5.16 Alloy ingots.

[0058] (2) Remelting and spray-casting the alloy ingots obtained in step (1) respectively to obtain corresponding alloy strips.

[0059] (3) Coarsely crushing the alloy strip obtained in step (2) to obtain powder passing through a 60-mesh sieve.

[0060] (4) Mix the alloy powder obtained in step (3) with an organic binder (PVA glue) to obtain a diffusing agent.

[0061] (5) Use a 52M sintered NdFeB magnet as the diffusion substrate, cut into a cuboid sample by wire cutting, the size is 7×7×12mm, and the direction of the thickness of 12mm is the c-axis direction. After polishing it to a mirror surface, it was ultrasonically cleaned in acetone and absolute ethanol for 15 min.

[0062] (6) Spray the diffusion agent obtained in step (4) on the edge of the magnet obtained i...

Embodiment 3

[0066] In this example, high coercive force NdFeB magnets are prepared by Pr-Tb-Al-Cu diffusion:

[0067] (1) Preparation of heavy rare earth-containing Pr by arc melting 42.26 Tb 47.67 Al 4.63 Cu 5.44 (wt%) alloy ingot.

[0068] (2) Remelting and spray-casting the alloy ingots obtained in step (1) respectively to obtain corresponding alloy strips.

[0069] (3) Coarsely crushing the alloy strip obtained in step (2) to obtain powder passing through a 60-mesh sieve.

[0070] (4) Mix the alloy powder obtained in step (3) with an organic binder (PVA glue) to obtain a diffusing agent.

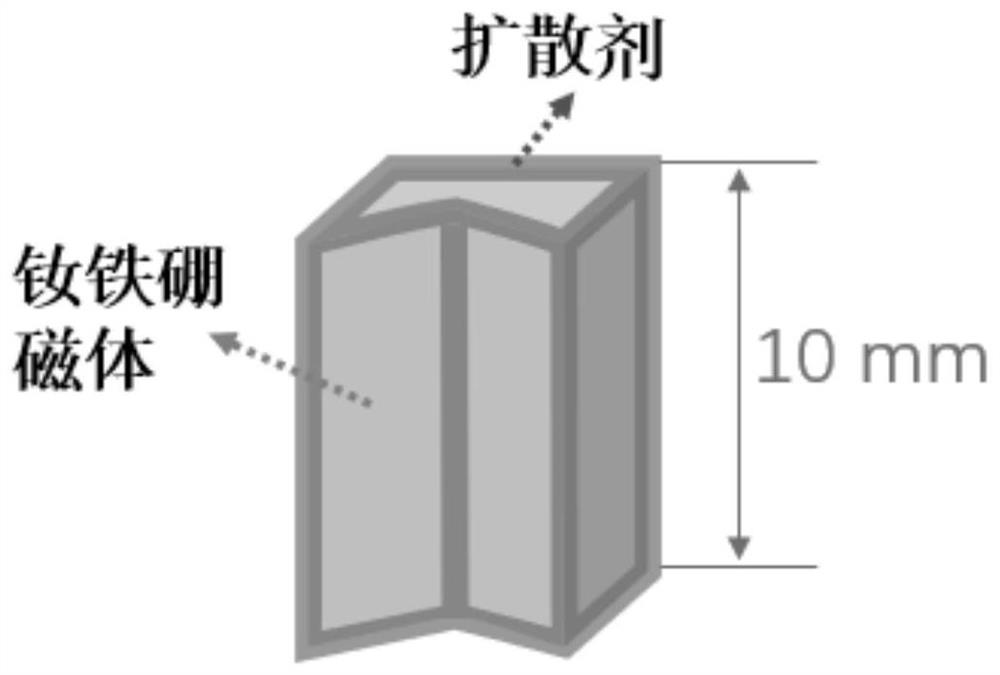

[0071] (5) Use N50 sintered NdFeB magnets as the diffusion substrate, and cut them into special-shaped samples by wire cutting, with dimensions such as image 3 As shown, the 10mm thickness direction is the c-axis direction. After polishing it to a mirror surface, it was ultrasonically cleaned in acetone and absolute ethanol for 15 min.

[0072] (6) Apply the diffusion agent obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com