A kind of extraction-stripping system based on alkanol deep eutectic solvent and its application

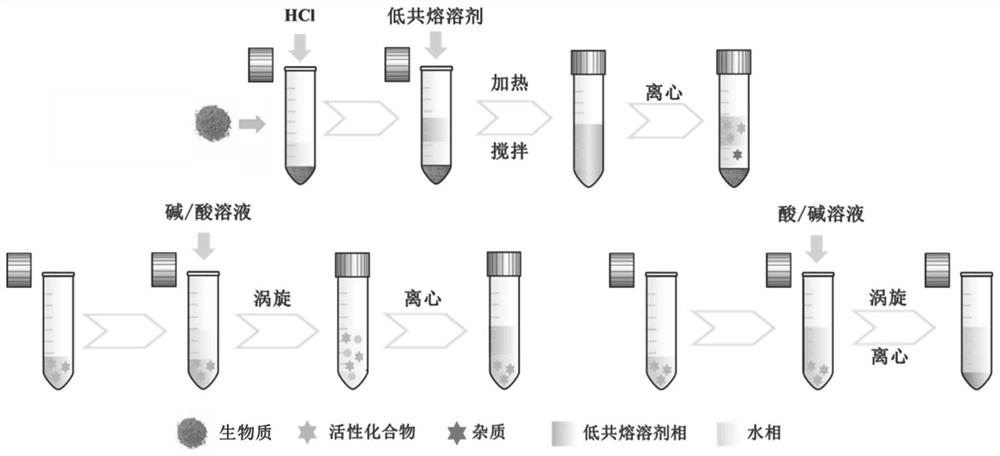

A low eutectic solvent and alkanol technology, applied in the field of separation and purification of natural products, can solve the problems of complicated heating and reflux extraction technology, loss of activity of target compounds, time-consuming and labor-intensive operation procedures, etc., and achieves low toxicity and purification steps. Less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

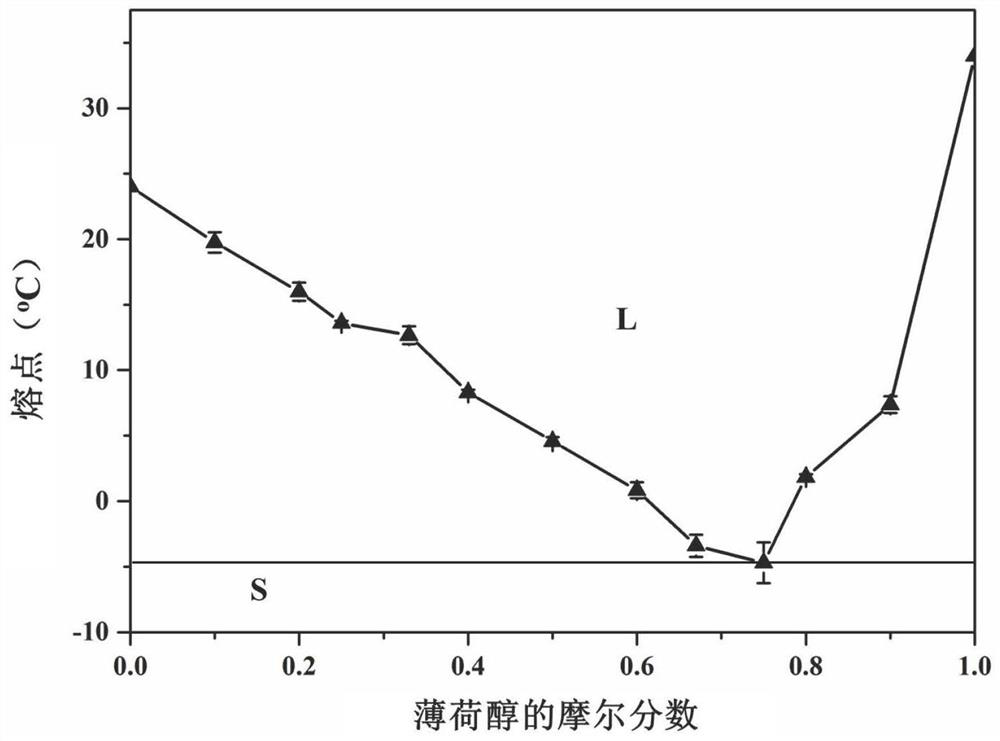

[0039] Example 1: Solid-liquid phase mapping of alkanol-based deep eutectic solvents

[0040] Precisely weigh 1-dodecanol and menthol in a series of molar ratios respectively (the molar ratio of 1-dodecanol and menthol is 9:1, 4:1, 3:1, 2:1, 3: 2, 1: 1, 2: 3, 1: 2, 1: 3, 1: 4, 1: 9) in a glass vial, and heat until a homogeneous liquid is formed. The solid-liquid phase diagram of a deep eutectic solvent is drawn by plotting the melting points corresponding to different molar ratios of the eutectic mixture. The melting point (Tm) is determined by recording the temperature at which the liquid deep eutectic solvent begins to solidify. like figure 2 As shown, as the mole fraction of hydrogen bond acceptor—menthol increases, the melting point of the deep eutectic solvent first drops to a lowest point and then rises, and the lowest point reached is the deep eutectic solvent of the deep eutectic solvent. melting point. The melting point of 1-dodecanol:menthol deep eutectic solven...

Embodiment 2

[0041] Example 2: Determination of physicochemical properties of alkanol-based deep eutectic solvents

[0042] 1) 1-dodecanol: menthol mol ratio is the preparation of the deep eutectic solvent of 1:3

[0043] Precisely weigh 1-dodecanol and menthol in a low eutectic ratio (mol ratio of 1-dodecanol and menthol is 1:3) in a glass vial and heat (40-80°C) to form a homogeneous liquid, It is the 1-dodecanol-menthol eutectic solvent successfully synthesized.

[0044] 2) Determine the viscosity and density of the above alkanol deep eutectic solvent

[0045] Viscosity was measured using a rotational rheometer under the following conditions: temperature 25°C, shear rate 0.1-1000s -1 , The distance between parallel plates is 40mm, and the test time is 11min; Density determination: At room temperature, use a pipette to absorb 100μL of the eutectic solvent, and then use an analytical balance to weigh the increased mass (Δm) of the pipette tip, and repeat the process six times. And calc...

Embodiment 3

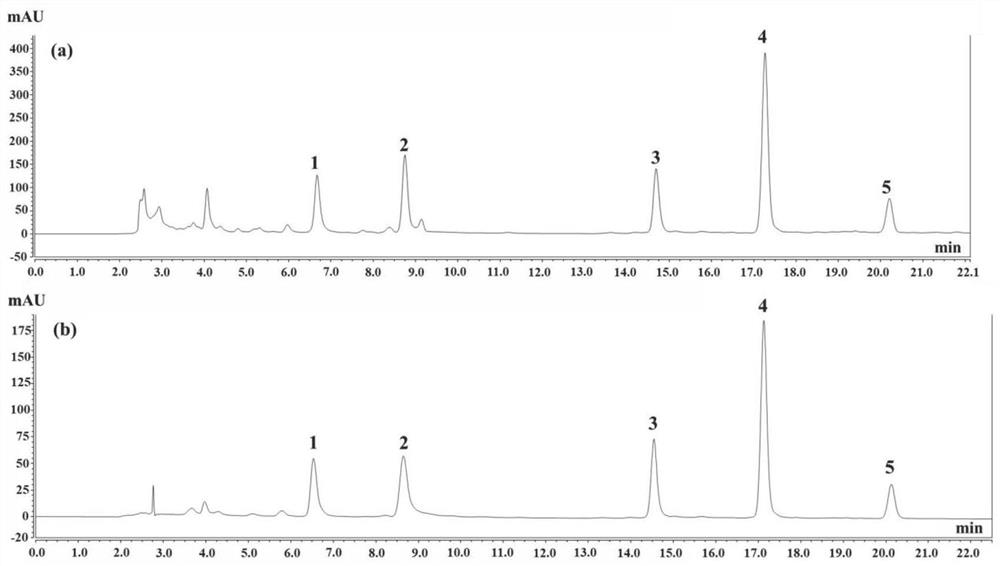

[0058] Example 3: Alkanol-based purification method construction of deep eutectic solvents

[0059] Precisely weigh 5mg of 1,8-dihydroxyanthraquinone and dissolve it in 5mL of a deep eutectic solvent with a molar ratio of 1-dodecanol and menthol of 1:3 to prepare 1,8-dihydroxyanthracene with a concentration of 1mg / mL. Quinones in deep eutectic solvent. Precisely measure 500 μL of the above 1,8-dihydroxyanthraquinone solution in deep eutectic solvent and 1 mL of 0.1 M NaOH solution, mix, vortex for 5 min, and centrifuge at 6000 rpm for 5 min, which is recorded as 1 back-extraction; use a 1 mL syringe to remove the NaOH water After the phase, 1 mL of 0.1M NaOH solution was added again, mixed by vortex, centrifuged, and recorded as 2 times of back-extraction; the above operations were repeated for 3 times of back-extraction and 4 times of back-extraction respectively. The deep eutectic solvent phase obtained in different times of back-extraction (0, 1, 2, 3, and 4 times) was tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com