Treatment method and treatment equipment for wastewater in animal husbandry processing plant

A wastewater treatment and processing plant technology, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve ecological environment and human health damage, downstream processing complexity, wastewater pollution, etc. problems, to achieve the effects of improving efficiency and treatment quality, providing wastewater treatment effects, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

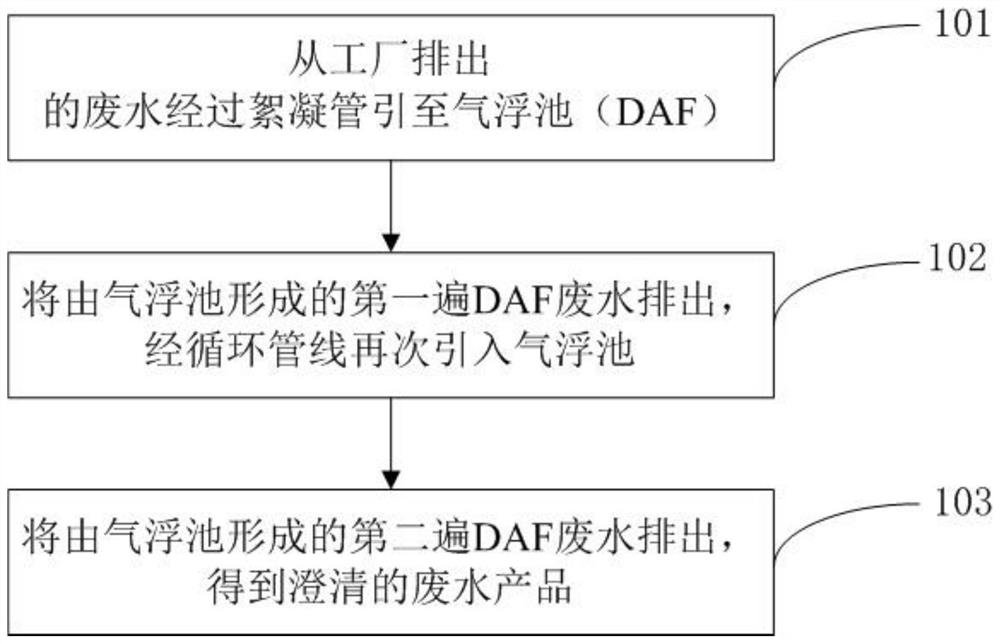

[0042] as attached figure 1 Shown, a kind of livestock processing plant wastewater treatment method comprises the following steps:

[0043] 101. The waste water discharged from the factory is led to the air flotation tank (DAF) through the flocculation pipe.

[0044] Wastewater contains one or more pollutants, wherein the pollutants include one of peracetic acid (PAA), quaternary ammonium compound (Quat), hydrogen peroxide, chlorine, chloramine, chlorinated organics, and surfactants or several combinations.

[0045] The waste water is introduced into the first flocculation pipe, the first flocculation pipe is set downstream of the outflow of factory waste water, the coagulant is injected into the first flocculation pipe, and the effluent in the first flocculation pipe enters the air flotation tank through the second flocculation pipe, Inject flocculant into the second flocculation tube.

[0046] The coagulant is one or any combination of aluminum chloride, ferric chloride, ...

Embodiment 2

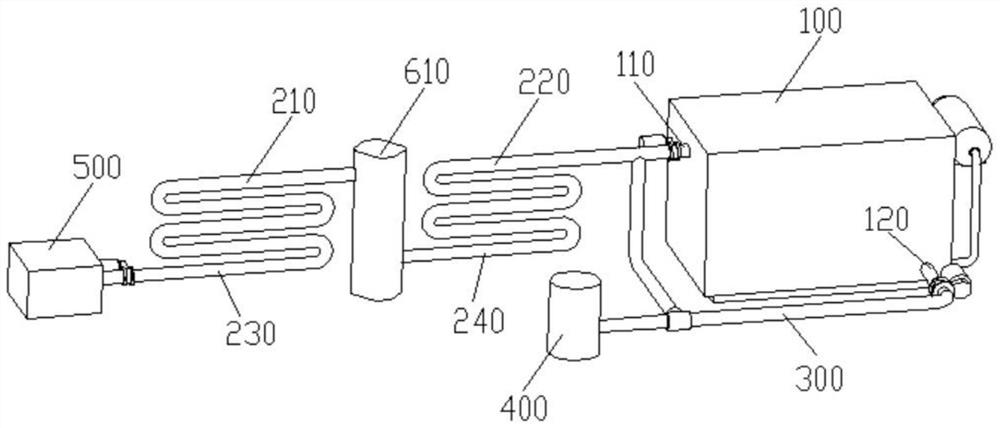

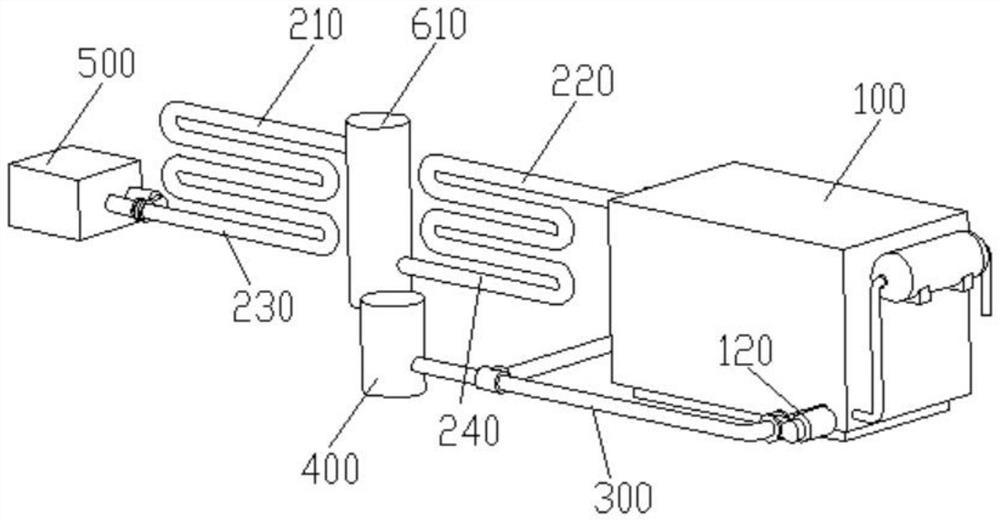

[0058] Based on Example 1, as attached figure 2 with 3 As shown, a wastewater treatment device in a livestock processing plant includes an air flotation tank 100, a first flocculation pipe 210, a second flocculation pipe 220, a circulation pipeline 300, and a first contact tank 610. One end of the first flocculation pipe 210 is connected to the factory wastewater The discharge port 500, the other end is connected to one end of the second flocculation pipe 220, and the other end of the second flocculation pipe 220 is connected to the water inlet 110 of the air flotation tank 100; one end of the circulation pipeline 300 is connected to the outlet 120 of the air flotation tank 100, and the other end is connected to the air flotation tank 100. One end is connected to the water inlet 110 of the air flotation tank 100 to realize the first cycle of DAF wastewater treatment.

[0059] Further, a drainage pump is provided at the waste water outlet 500 to realize waste water transmissi...

Embodiment 3

[0068] Based on above-mentioned embodiment 1, a kind of livestock processing plant wastewater treatment method comprises the following steps:

[0069] 101. The waste water discharged from the factory is led to the air flotation tank (DAF) through the flocculation pipe.

[0070] Wastewater contains one or more pollutants, wherein the pollutants include one of peracetic acid (PAA), quaternary ammonium compound (Quat), hydrogen peroxide, chlorine, chloramine, chlorinated organics, and surfactants or several combinations.

[0071] The waste water is introduced into the first flocculation pipe, the first flocculation pipe is arranged downstream of the outflow of factory waste water, the coagulant is injected into the first flocculation pipe, and the effluent in the first flocculation pipe is introduced into the first contact tank, the first contact tank The effluent in the water enters the air flotation tank through the second flocculation pipe, and the flocculant is injected into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com