Method for preparing building gypsum powder from ardealite

A technology for building gypsum powder and phosphogypsum, which is applied in the field of phosphogypsum reuse, can solve the problems of high calcination temperature, high energy consumption, unstable product properties, etc., and achieves the effects of improving purity, low energy consumption and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

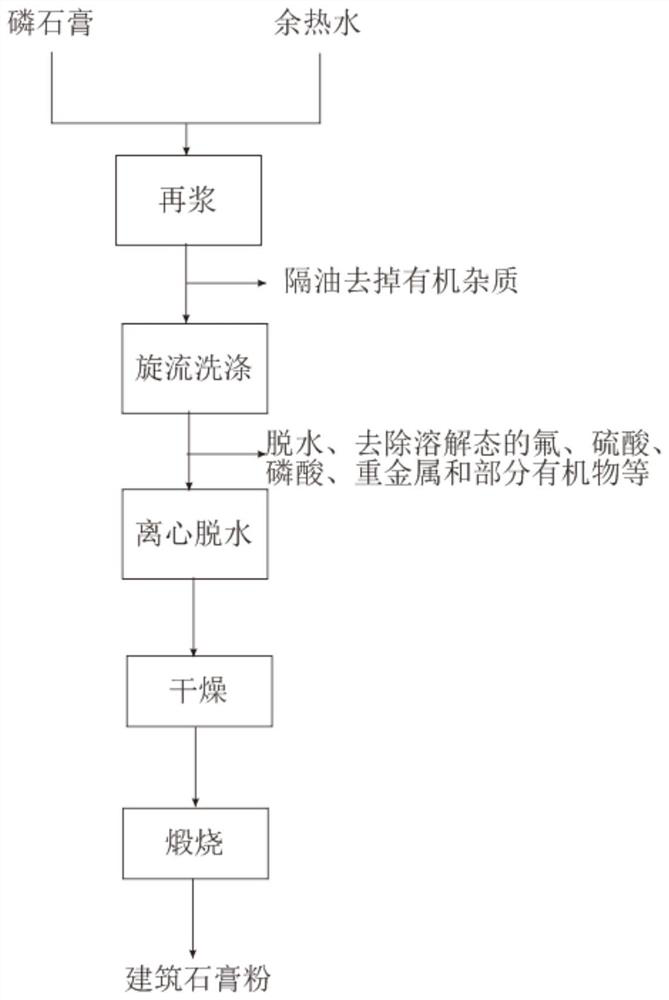

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing building gypsum powder with phosphogypsum, comprising the following steps:

[0032] (1) Mix phosphogypsum and residual hot water at 50°C according to the solid-to-liquid ratio of 1:8 under agitation and re-slurry, then let it stand for 5 minutes, and then remove the oily impurities on the surface of the slurry;

[0033] (2) Put the slurry in step (1) into the cyclone separator for cyclone separation. The cylinder diameter of the cyclone separator is 300mm, the diameter of the overflow pipe is 80mm, the feeding pressure is 0.1MPa, and the cyclone separation time is 30s , to collect the final bottom slag;

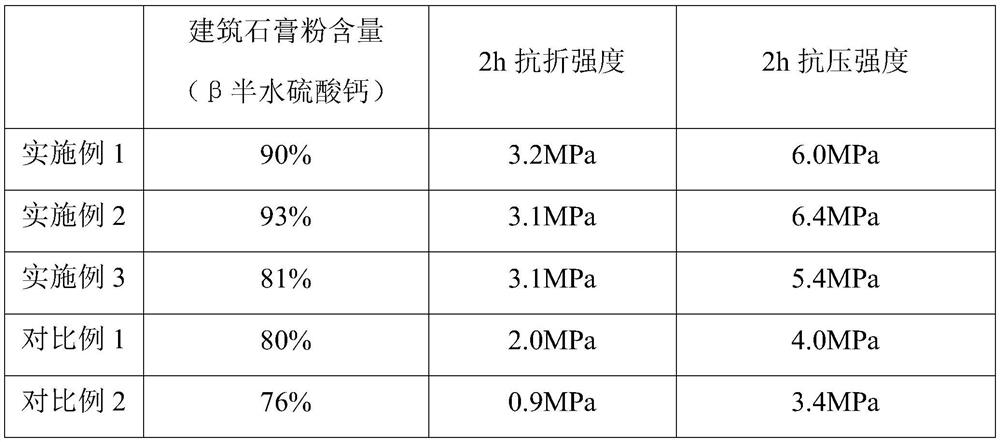

[0034] (3) Centrifuge and dehydrate the bottom slag in step (2) to a moisture content of 10% to obtain a phosphogypsum wet material, then dry the phosphogypsum wet material at 80°C for 1 hour, and then calcinate at 150°C 2h, prepared.

Embodiment 2

[0036] A method for preparing building gypsum powder with phosphogypsum, comprising the following steps:

[0037] (1) Mix phosphogypsum and residual hot water at 80°C according to the solid-to-liquid ratio of 1:15 under agitation, then re-slurry and let it stand for 3 minutes, and then remove the oily impurities on the surface of the slurry;

[0038] (2) Set aside the slurry in step (1), and then put it into the cyclone separator for cyclone separation. The cylinder diameter of the cyclone separator is 350 mm, the diameter of the overflow pipe is 120 mm, and the feeding pressure is 0.3 MPa, the cyclone separation time is 30s, and the final bottom slag is collected;

[0039] (3) Centrifuge and dehydrate the bottom slag in step (2) to a moisture content of 11% to obtain a phosphogypsum wet material, then dry the phosphogypsum wet material at 90°C for 0.5h, and then dry the phosphogypsum wet material at 180°C Calcined for 1h, obtained.

Embodiment 3

[0041] A method for preparing building gypsum powder with phosphogypsum, comprising the following steps:

[0042] (1) Mix phosphogypsum and residual hot water at 65°C according to the solid-to-liquid ratio of 1:10 under agitation and re-slurry, then let it stand for 5 minutes, and then remove the oily impurities on the surface of the slurry;

[0043](2) Set aside the slurry in step (1), and then put it into the cyclone separator for cyclone separation. The cylinder diameter of the cyclone separator is 350 mm, the diameter of the overflow pipe is 120 mm, and the feeding pressure is 0.3 MPa, the cyclone separation time is 30s, and the final bottom slag is collected;

[0044] (3) Centrifuge and dehydrate the bottom slag in step (2) to a moisture content of 10% to obtain a phosphogypsum wet material, then dry the phosphogypsum wet material at 85°C for 0.7h, and then dry the phosphogypsum wet material at 165°C Calcined for 1.5h, obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com