Homoepitaxial beta-Ga2O3 film and preparation method thereof

A homoepitaxial, -ga2o3 technology, applied in the field of microelectronics, can solve problems such as rough surface morphology, device leakage, and reduce carrier mobility, and achieve enhanced two-dimensional growth, improved device performance, and reduced dislocation density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

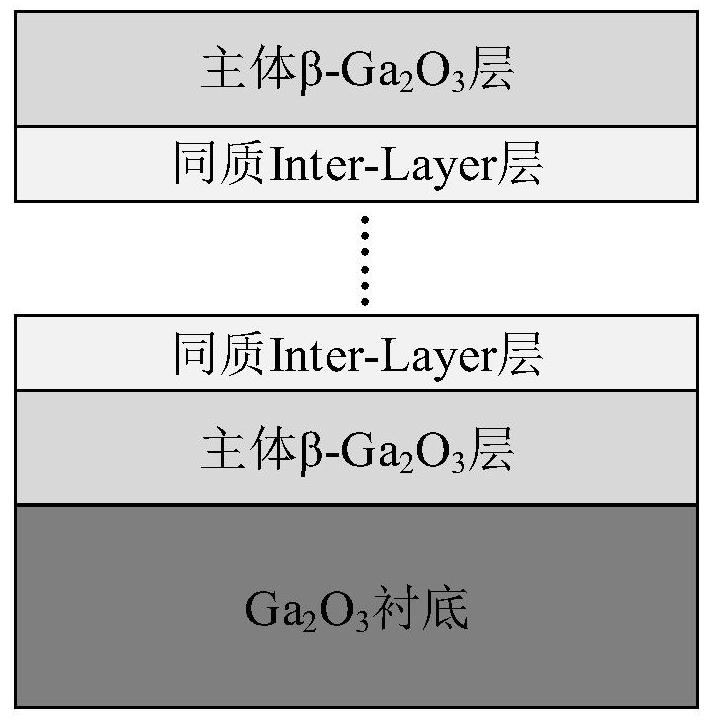

[0036] See figure 1 , figure 1 It is a kind of homoepitaxial β-Ga provided by the embodiment of the present invention 2 o 3 Schematic diagram of the structure of thin films, including Ga 2 o 3 substrate and located at Ga 2 o 3Layered β-Ga on a substrate 2 o 3 structure, where layered β-Ga 2 o 3 The structure consists of several spaced apart host β-Ga 2 o 3 layer and homogeneous Inter-Layer layer, and layered β-Ga 2 o 3 The top and bottom layers of the structure are host β-Ga 2 o 3 layer; the grain size of each homogeneous Inter-Layer layer is the same as that of two adjacent host β-Ga 2 o 3 The layers differ in grain size.

[0037] In this embodiment, the homogeneous Inter-Layer layer and the host β-Ga 2 o 3 The material of the layers is the same, that is, β-Ga 2 o 3 Inter-Layer layer.

[0038] Further, the host β-Ga 2 o 3 The thickness of the layer is greater than that of the homogeneous Inter-Layer layer.

[0039] Theoretically, the thicker the homog...

Embodiment 2

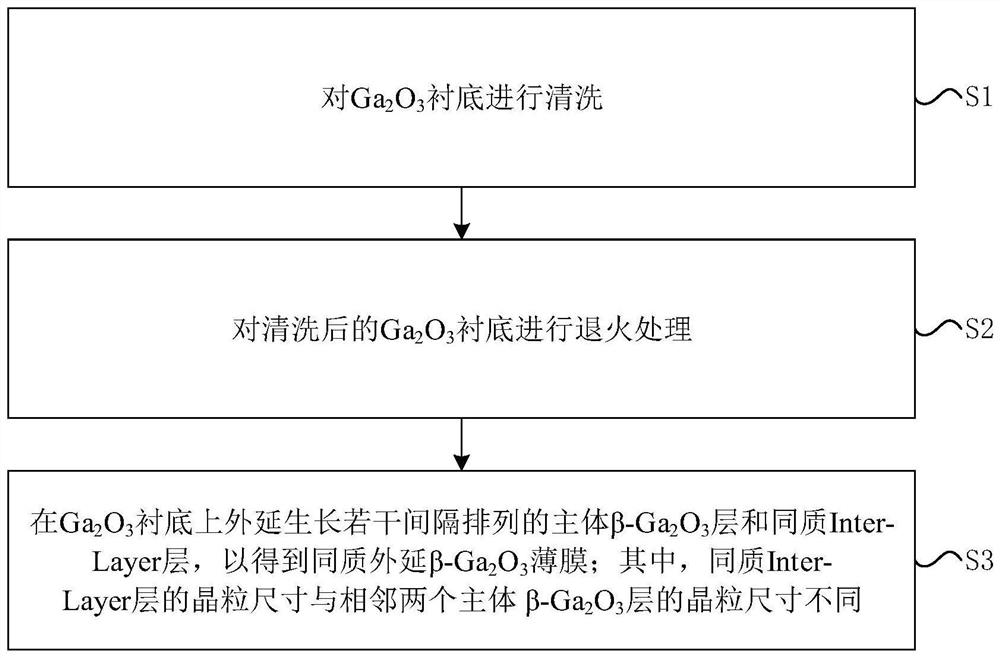

[0045] On the basis of the first embodiment above, this embodiment provides a homoepitaxial β-Ga 2 o 3 The method of film preparation. See image 3 , image 3 It is a kind of homoepitaxial β-Ga provided by the embodiment of the present invention 2 o 3 Schematic diagram of the preparation method of the film, specifically comprising the following steps:

[0046] S1: for Ga 2 o 3 The substrate is cleaned.

[0047] In this embodiment, the RCA standard cleaning method is used to clean the β-Ga 2 o 3 The substrate is cleaned. Specifically include:

[0048] S11: to β-Ga 2 o 3 The substrates were sequentially cleaned with organic and deionized water.

[0049] First, for Ga 2 o 3 The substrate is polished, and then the polished Ga 2 o 3 The substrate is cleaned in an organic cleaning solution at 60-80°C for 15-20 minutes to remove organic contamination on the substrate surface; finally, the organic-cleaned substrate is cleaned with flowing deionized water for 40-60 se...

Embodiment 3

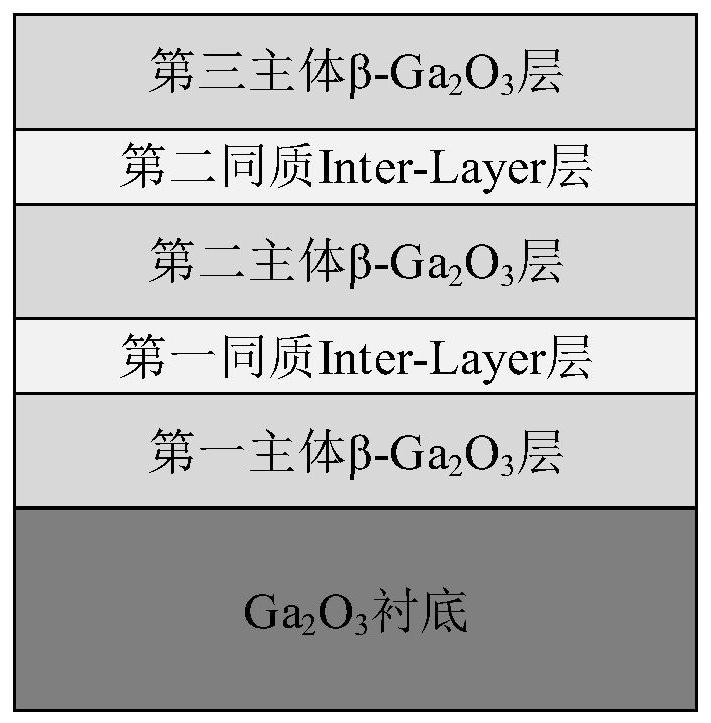

[0071] On the basis of the second embodiment above, this embodiment grows three layers of main body β-Ga 2 o 3 layer and two Inter-Layer layers as examples, the specific preparation process of the present invention will be described in detail. See Figures 4a-4f , Figures 4a-4f It is a kind of homoepitaxial β-Ga provided by the embodiment of the present invention 2 o 3 Schematic diagram of the preparation process of the film, specifically including:

[0072] Step 1: Select single crystal β-Ga 2 o 3 As a substrate material, such as Figure 4a As shown, it is then polished and standardized to clean; this includes:

[0073] 1a) The polished Ga 2 o 3 The substrate is cleaned in an organic cleaning solution at 80°C for 20 minutes;

[0074] 1b) Cleaning the organically cleaned substrate with flowing deionized water for 40 seconds;

[0075] 1c) putting the cleaned substrate into a solution with HF content of 30% and corroding for 60s;

[0076] 1d) The etched β-Ga 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com