Thermosensitive detector structure and integration method thereof

An integration method and detector technology, applied in electrical radiation detectors, semiconductor devices, photovoltaic power generation, etc., can solve the problems of insufficient performance, low infrared light absorption rate, etc., to reduce the length of interconnect lines, simplify the integration process, The effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

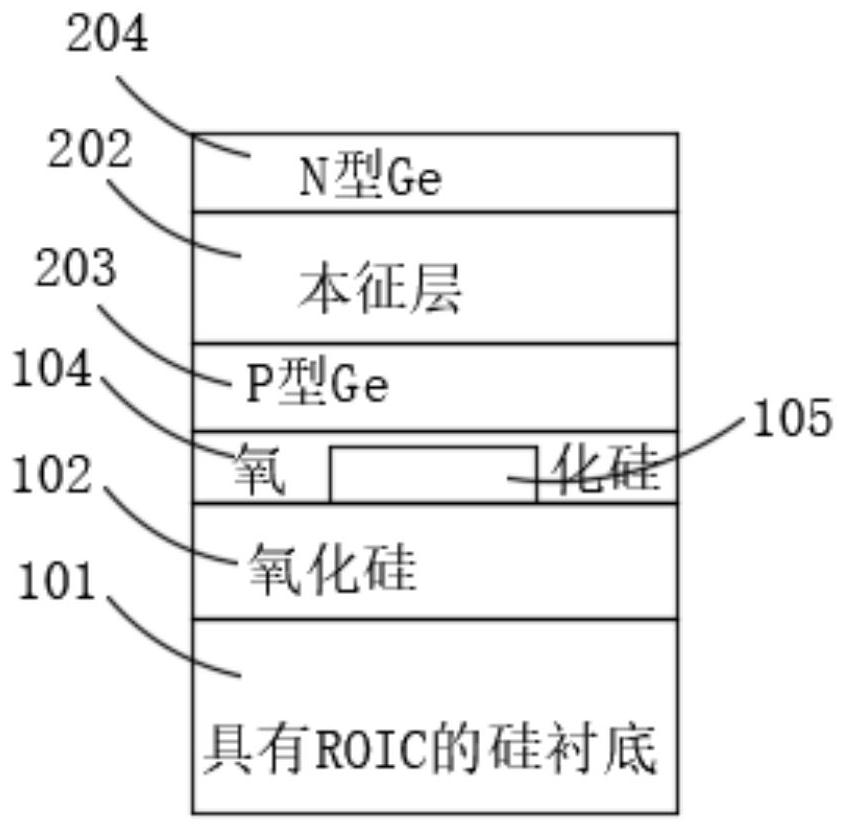

[0058] Embodiment 1 A heat-sensitive detector structure

[0059] Make the supporting substrate:

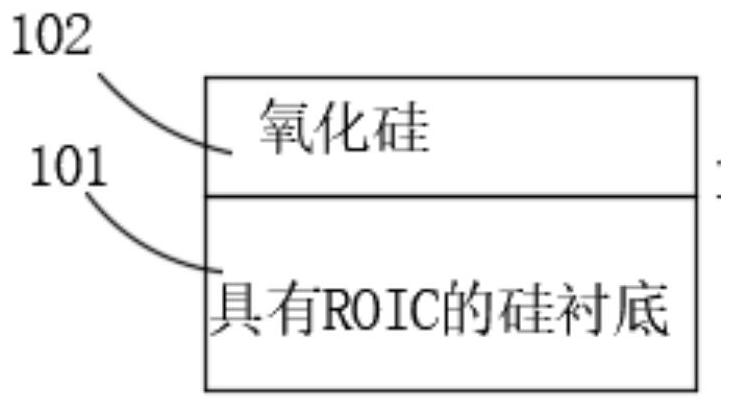

[0060] Provide a substrate 101 with a readout circuit structure, and then deposit a first silicon oxide layer 102 on the surface of the readout circuit structure, to obtain the following figure 2 structure shown.

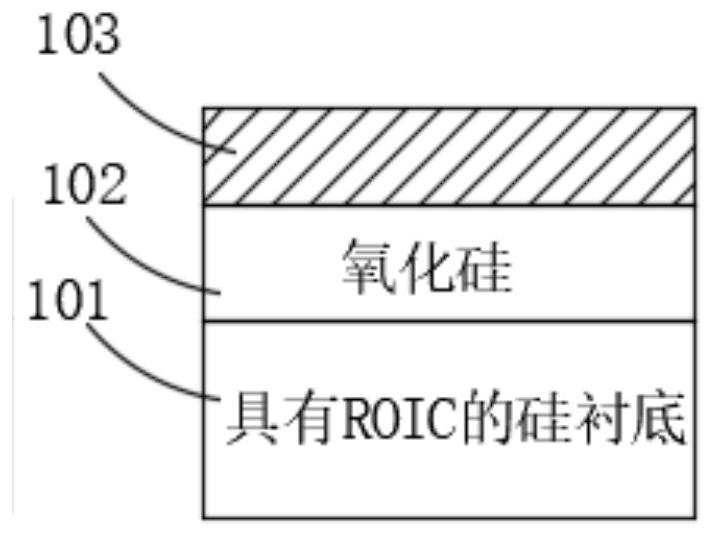

[0061] An amorphous silicon layer 103 is deposited on the surface of the first silicon oxide layer 102 to obtain the following image 3 structure shown.

[0062] Perform photolithography and etching on the amorphous silicon layer 103, remove part of the amorphous silicon, so that it only covers part of the surface of the first silicon oxide layer 103, and obtain the following: Figure 4 structure shown.

[0063] Deposit the second silicon oxide layer 104, the second silicon oxide layer 104 borders the first silicon oxide layer 102 and wraps the amorphous silicon layer to obtain the following Figure 5 For the structure shown, a planarization process (such as CMP) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com