Fruit enzyme and preparation method thereof

A technology of fruit enzymes and fermentation methods, applied in the direction of bacteria used in food preparation, functions of food ingredients, food science, etc., can solve problems such as unachievable effects, achieve good taste and flavor, enhance antioxidant activity, and improve fermentation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

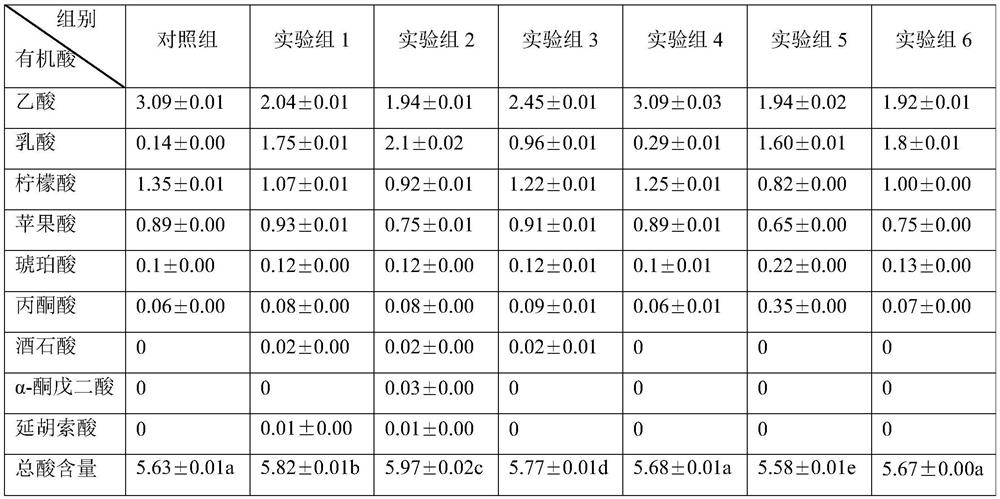

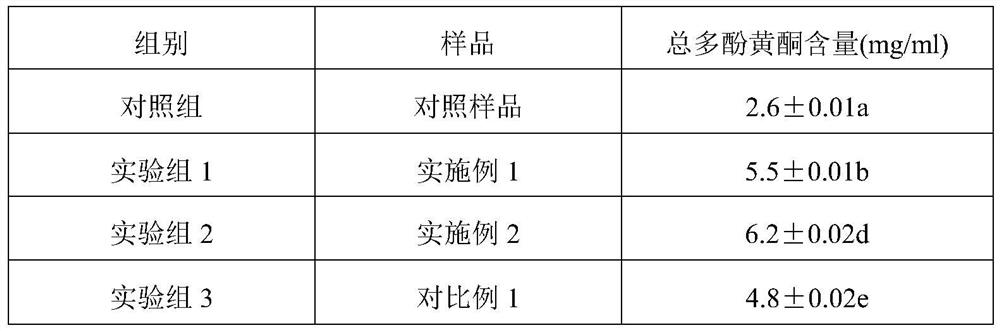

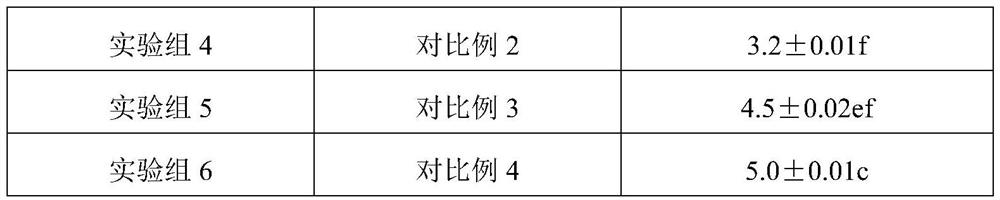

[0024] Embodiment 1: the preparation method of high-quality ferment containing polyphenolic flavonoids

[0025] (1) Raw material pretreatment: wash the ebony plum, remove the nucleus and beat the pulp, divide the pulp into two parts, add cellulase and pectinase with 0.5% of the total mass of the raw material respectively, the enzymolysis temperature is 45°C, and the enzymolysis time After 2.5 hours, two kinds of enzymolyzed fruit pulps were obtained, and the two kinds of enzymatically hydrolyzed pulps were mixed according to the mass ratio of 6:4 for later use;

[0026] (2) Alcoholic fermentation: add 10 10 Saccharomyces cerevisiae CICC 1012 per kg, supplemented with 1% glucose after 24 hours of fermentation at 30°C, and then added 10 12 Lactobacillus fermentum CGMCCNo.12934 per kg, stirred once every 1 day, and fermented for 6 days in a closed environment;

[0027] (3) acetic acid fermentation: add 10 12 Lactobacillus plantarum CGMCCNo.18388 and 10 per kg 8 Bacillus Velez...

Embodiment 2

[0032] Embodiment 2: the preparation method of high-quality ferment containing polyphenolic flavonoids

[0033] (1) Raw material pretreatment: wash the ebony plum, remove the nucleus and beat the pulp, divide the pulp into two parts, add cellulase and pectinase with 0.5% of the total mass of the raw material respectively, the enzymolysis temperature is 45°C, and the enzymolysis time After 2.5 hours, two kinds of enzymolyzed fruit pulps were obtained, and the two kinds of enzymatically hydrolyzed pulps were mixed according to the mass ratio of 7:3 for later use;

[0034] (2) Alcoholic fermentation: add 10 12 Saccharomyces cerevisiae CICC 1012 per kg, supplemented with 2% glucose after 24 hours of fermentation at 30°C, and then added 10 13Lactobacillus fermentum CGMCCNo.12934 per kg, stirred once every 1 day, and fermented for 6 days in a closed environment;

[0035] (3) acetic acid fermentation: add 10 14 Lactobacillus plantarum CGMCCNo.18388 and 10 per kg 10 Bacillus Velez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com