Preparation method of plasma separation membrane

A technology of plasma separation membrane and diamino, applied in the field of plasma separation membrane, can solve the problems of hemolysis separation accuracy and efficiency, and achieve the effect of low cost, simple process and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

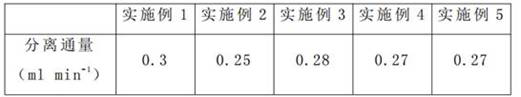

Embodiment 1

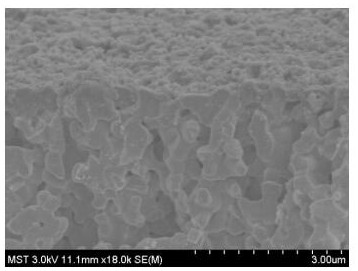

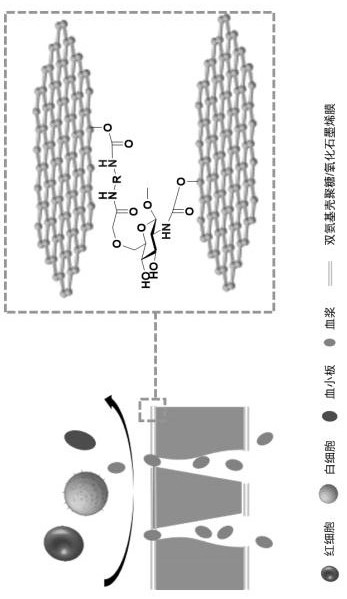

[0027] This example provides the specific preparation process of the plasma separation membrane.

[0028] O-carboxymethyl chitosan was dissolved in 10 ml DMSO (0.05 M concentration), and HOBT (0.005 M), N-tert-butoxycarbonylethylenediamine (0.05 M) and EDCI ( 0.1 M), stirring at 100rpm, reacting at 0°C for 36h, filtering and washing with saturated sodium carbonate solution to obtain bisaminochitosan derivatives protected by tert-butoxycarbonyl groups, adding 5ml trifluoroacetic acid for 2h and then adding 30ml saturated carbonic acid The sodium aqueous solution was stirred for 1 h, filtered and washed with 20 ml of saturated sodium bicarbonate solution to obtain bisamino chitosan derivatives. The prepared diaminochitosan derivative (0.1g) was blended with graphene oxide (0.1g). After ultrasonication for 45min, DMAP (0.23g) and DCC (2.3g) were added, and stirred at reflux for 36 h. The solution was washed with deionized water, methanol, and acetone each with 30ml, and then dri...

Embodiment 2

[0031] (1) Dissolve O-carboxymethyl chitosan in 10 ml of dichloromethane (concentration: 0.15 M), add HOBT (0.15 M), N-tert-butoxycarbonylethylenediamine (0.3 M) and EDCI (0.3 M), stirred at 800rpm, reacted at 30°C for 12h, filtered and washed with saturated sodium bicarbonate to obtain a bisaminochitosan derivative protected by tert-butoxycarbonyl, added 5ml trifluoroacetic acid to react for 2h Then add potassium carbonate aqueous solution and continue to stir for 1 h, obtain bisamino chitosan derivatives after filtering and washing. Add 8ml of trifluoroacetic acid to react for 2h, add 40ml of saturated sodium carbonate aqueous solution and continue to stir for 2h, filter and wash with 20ml of saturated sodium bicarbonate solution to obtain diaminochitosan derivatives. The prepared diaminochitosan derivative (0.15g) was blended with graphene oxide (0.1g). After ultrasonication for 60min, DMAP (0.23g) and DCC (2.3g) were added and stirred at reflux for 24 h. The solution was ...

Embodiment 3

[0034](1) Dissolve O-carboxymethyl chitosan in 10 ml of chloroform (concentration: 0.1 M), add HOBT (0.02 M), N-tert-butoxycarbonylethylenediamine (0.1 M) to the mixed solution and EDCI (0.15 M), stirring at 1000 rpm, reacting at 10 degrees for 24 hours, filtering and washing with saturated potassium carbonate solution, to obtain bisaminochitosan derivatives protected by tert-butoxycarbonyl groups, adding 15ml of trifluoroacetic acid to react for 12 hours and then adding 100ml of saturated aqueous sodium carbonate solution continued to stir for 4h, filtered and washed with 20ml of saturated sodium bicarbonate solution to obtain a diaminochitosan derivative. The prepared diaminochitosan derivative (0.1g) was blended with graphene oxide (0.15g). After ultrasonication for 30min, DMAP (0.23g) and DCC (2.3g) were added and stirred at reflux for 48 h. The solution was washed with deionized water, methanol, and acetone with 30ml each, and then dried at 30°C for 48h to obtain a diamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com