Micro-fluidic chip and preparation and application thereof

A microfluidic chip and channel layer technology, applied in the field of microfluidics, can solve the problems of lack of effective separation methods, inability to meet high sensitivity, and difficulty in popularization and application, so as to facilitate industrial promotion and application, improve mixing efficiency, and the method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

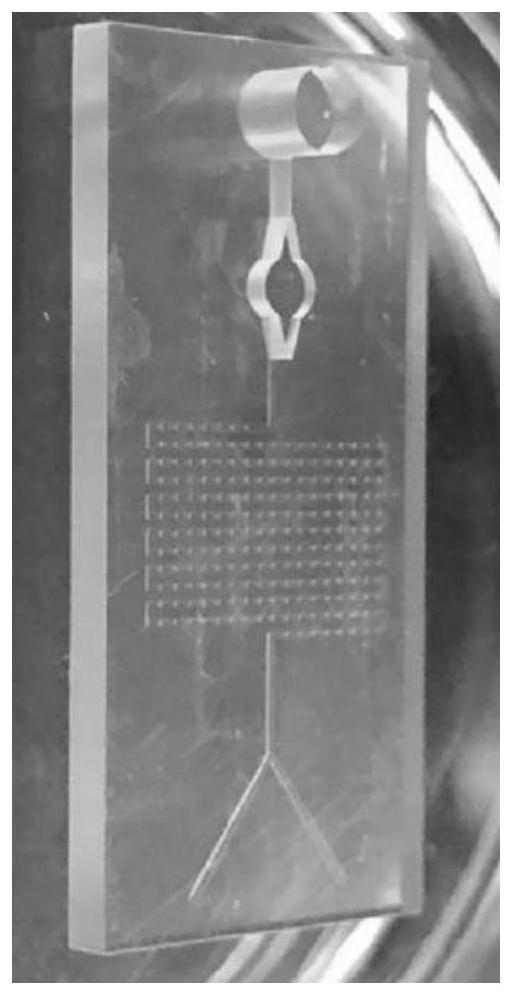

[0038] This embodiment provides a microfluidic chip, including a channel layer and a base layer, wherein the channel layer is bonded to the base layer by means of surface plasma treatment.

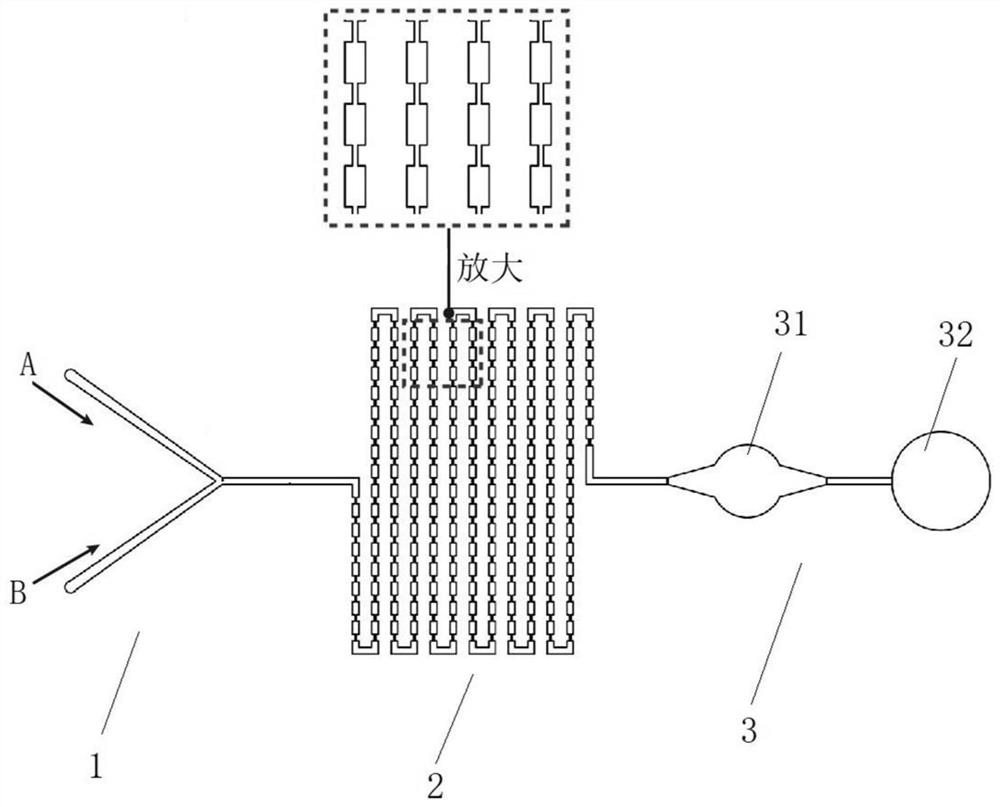

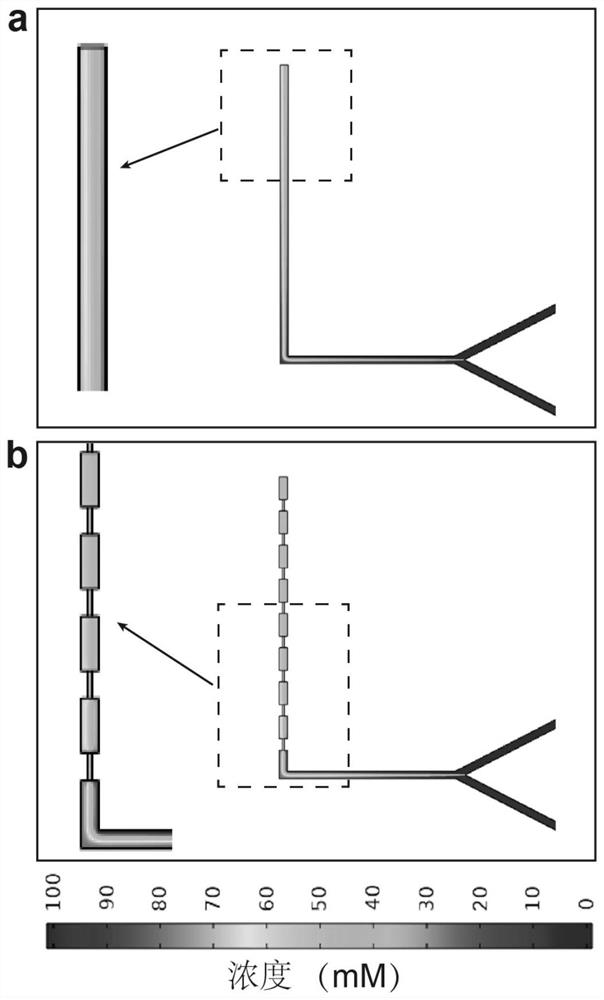

[0039] Among them, the further structural features of the channel layer are as attached figure 1 As shown, the above-mentioned channel layer includes a sampling area 1 , a mixing area 2 and a detection area 3 connected in sequence. In this embodiment, the sampling region 1 includes two sampling ports, and the sampling channel is in the shape of a "Y", and the width and height of the "Y"-shaped channel are both on the order of microns. Specifically, in this embodiment, The width of the "Y"-shaped channel is designed to be 200 μm, and the height is designed to be 100 μm. Sample A and sample B are respectively input from two injection ports, and then enter the mixing area 2 through the above-mentioned injection channel.

[0040] In other embodiments, the sampling channel can also be designe...

Embodiment 2

[0051] This implementation provides a microfluidic chip, which includes a channel layer and a base layer, wherein the channel layer is bonded to the above base layer by means of surface plasma treatment, and the specific preparation method is the same as that in Example 1.

[0052] Further, the structure of the channel layer in this embodiment is the same as that in Embodiment 1. Further, the channel layer in this embodiment can be made of PDMS, but in addition, PMMA or vinyl polymer can also be used instead.

[0053] The base layer can be made of a glass plate or a polyethylene plate. In this embodiment, a glass plate is selected as the material for making the base layer, and the surface of the glass plate is decorated with distearoylphosphatidylethanolamine-polyethylene glycol (DSPE-PEG). ).

[0054] Further, the microfluidic chip of this embodiment also includes a magnet, as attached Figure 5 As shown, the magnet is disposed below the first chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com