Rapid membrane filtration device for treating backwash wastewater of filter tank and use method thereof

A technology for backwashing and waste water, which is applied in the direction of special treatment targets, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of increased chlorine consumption of organic matter, enrichment of metal elements, etc., and achieves floor space saving and easy operation , The effect of simple and convenient installation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

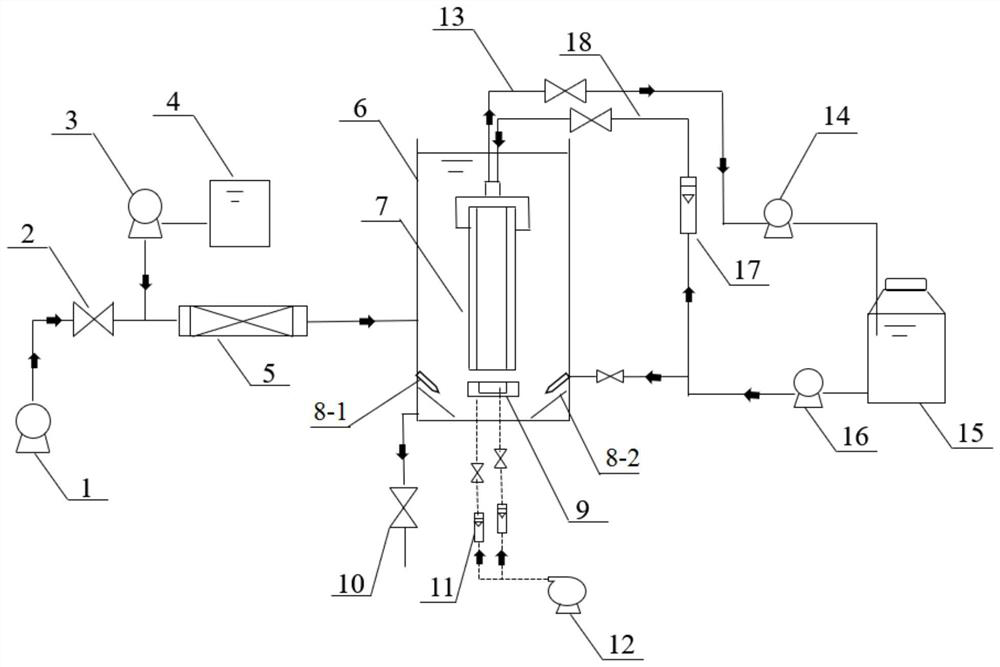

[0032] Specific implementation mode one: combine figure 1 and 2 This embodiment is described in detail. This embodiment is a fast membrane filtration device for treating filter backwash wastewater, which includes a submersible pump 1, a dosing box 4, a mixer 5, an ultrafiltration membrane pool 6, and an ultrafiltration membrane assembly 7. High-speed meter sweeping and mud discharge system, dual-channel aeration cleaning system 9 and ultrafiltration water production tank 15;

[0033] The submersible pump 1 is set in the raw water pool, and the submersible pump 1 is connected with the water inlet regulating valve 2 through the water inlet pipeline, and the water inlet regulating valve 2 is respectively connected with the dosing box 4 and the mixer 5 through the tee, and the mixer 5 The water outlet of the water outlet is communicated with the ultrafiltration membrane pool 6 through a pipeline;

[0034]The inside of the ultrafiltration membrane pool 6 is provided with an ultra...

specific Embodiment approach 2

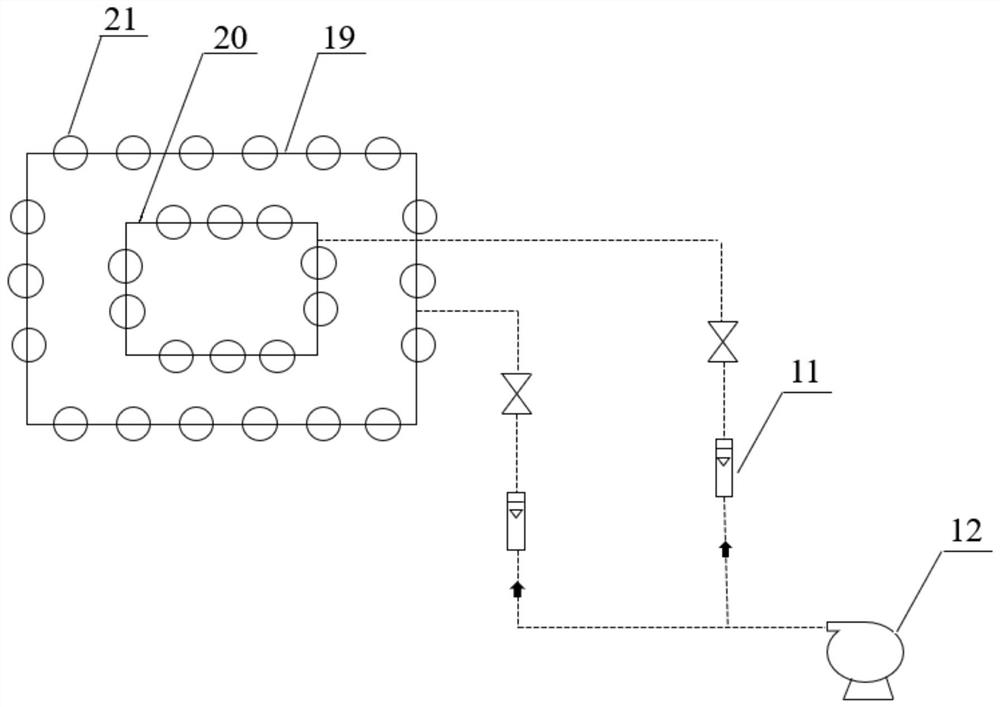

[0047] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the pipeline between the tee and the dosing box 4 is provided with a dosing pump 3; the described water production pipeline 13 is provided with a water production pump 14; the backwashing pipeline 18 is provided with a backwashing pump 16 and a flow meter 17; the external aeration passage 19 and the central aeration passage 20 are respectively connected to the blower 12 through two inlet pipes, and the two inlet pipes Gas flowmeters 11 are provided on the trachea. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the material of the ultrafiltration membrane in the ultrafiltration membrane module 7 is polyvinylidene fluoride, polyvinyl chloride, polyethersulfone or ceramic membrane ; The ultrafiltration membrane in the ultrafiltration membrane module 7 is a hollow fiber membrane with a molecular weight cut-off of 50,000 Daltons to 300,000 Daltons. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com