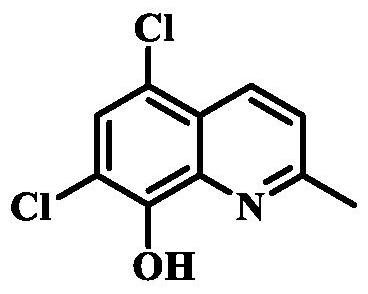

Preparation method of chlorquinaldol

A technology of chloroquinaldol and methylquinoline, which is applied in the field of drug synthesis, can solve the problems of large amount of sodium hypochlorite solution, increased cost of waste liquid treatment, and reduced yield, so as to avoid the generation and increase of impurities, and the requirements are not high. The effect of reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

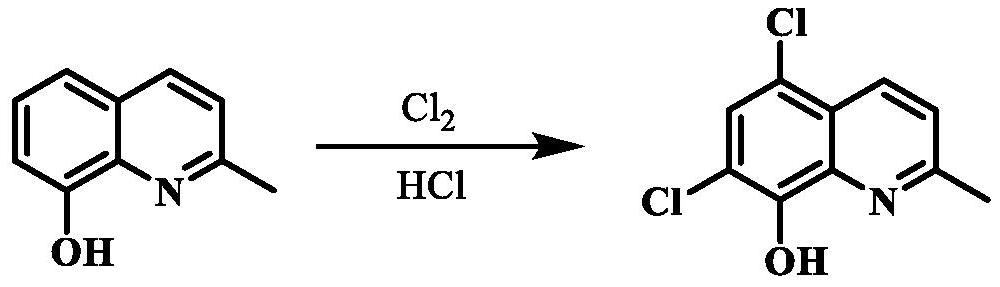

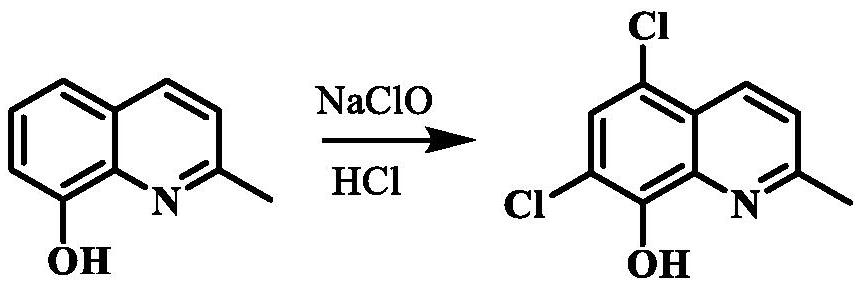

Method used

Image

Examples

Embodiment 1

[0064] Put 10g of 8-hydroxy-2-methylquinoline, 50mL of dichloromethane and 0.35g of aluminum chloride into a 250mL reaction bottle, stir and cool down to 20-30°C, add 7.8g of dichlorohydantoin, and keep warm at 32-41°C Reaction 7h.

[0065] Cool the reaction solution to 20-30°C, filter, add 15mL of concentrated hydrochloric acid dropwise to the filtrate, precipitate out, filter, add 150mL of water, stir to dissolve, slowly add ammonia water until the pH is 2.8, precipitate solid, filter, rinse, Dried rough.

[0066] The crude product was refined with 160 mL of absolute ethanol and 20 mL of water to obtain 8.7 g of pure chloroquinaldol, with a yield of 60.32% and a HPLC purity of 99.23%.

Embodiment 2

[0068] Put 20g of 8-hydroxy-2-methylquinoline, 200mL of chloroform and 1.0g of aluminum chloride into a 500mL reaction bottle, stir and cool down to 20-30°C, add 15.3g of dichlorohydantoin, and keep it warm at 32-41°C for 8h .

[0069] Cool the reaction solution to 20-30°C, filter, add 20mL of concentrated hydrochloric acid dropwise to the filtrate, precipitate out, filter, add 200mL of water, stir to dissolve, slowly add ammonia water until the pH is 3.5, precipitate solid, filter, rinse, Dried rough.

[0070] The crude product was refined with 280 mL of absolute ethanol and 30 mL of water to obtain 19.0 g of pure chloroquinaldol, with a yield of 65.85% and a HPLC purity of 99.43%.

Embodiment 3

[0072] Put 10g of 8-hydroxy-2-methylquinoline, 80mL of dichloromethane and 0.5g of aluminum chloride into a 250mL reaction bottle, stir and cool down to 20-30°C, add 7.7g of dichlorohydantoin, and keep warm at 32-41°C Reaction 9h.

[0073] Cool the reaction solution to 20-30°C, filter, add 12mL of concentrated hydrochloric acid dropwise into the filtrate, precipitate out, filter, add 100mL of water, stir to dissolve, slowly add ammonia water until the pH is 4.0, precipitate solid, filter, rinse, Dried rough.

[0074] The crude product was refined with 100 mL of acetonitrile and 10 mL of water to obtain 9.5 g of pure chloroquinaldol, with a yield of 66.05% and an HPLC purity of 99.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com