Method for preparing lignin nanotube by utilizing agriculture and forestry biomass raw materials

A biomass raw material, lignin technology, applied in the field of lignin nanotubes, can solve problems such as environmental pollution, complicated operation process, etc., and achieve the effects of simple and easy method, improved environmental performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

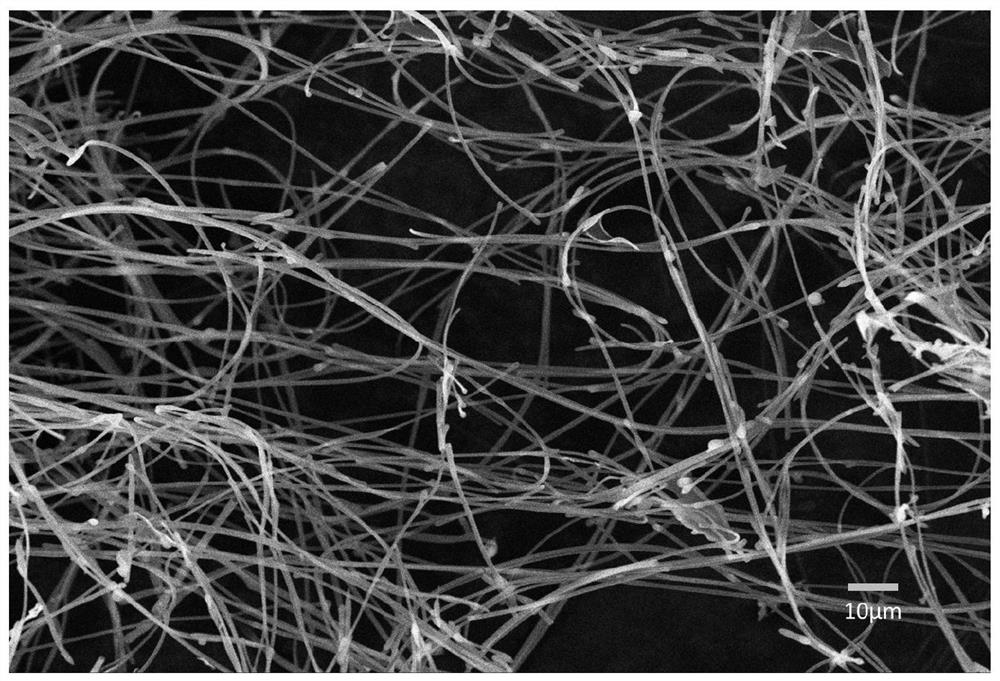

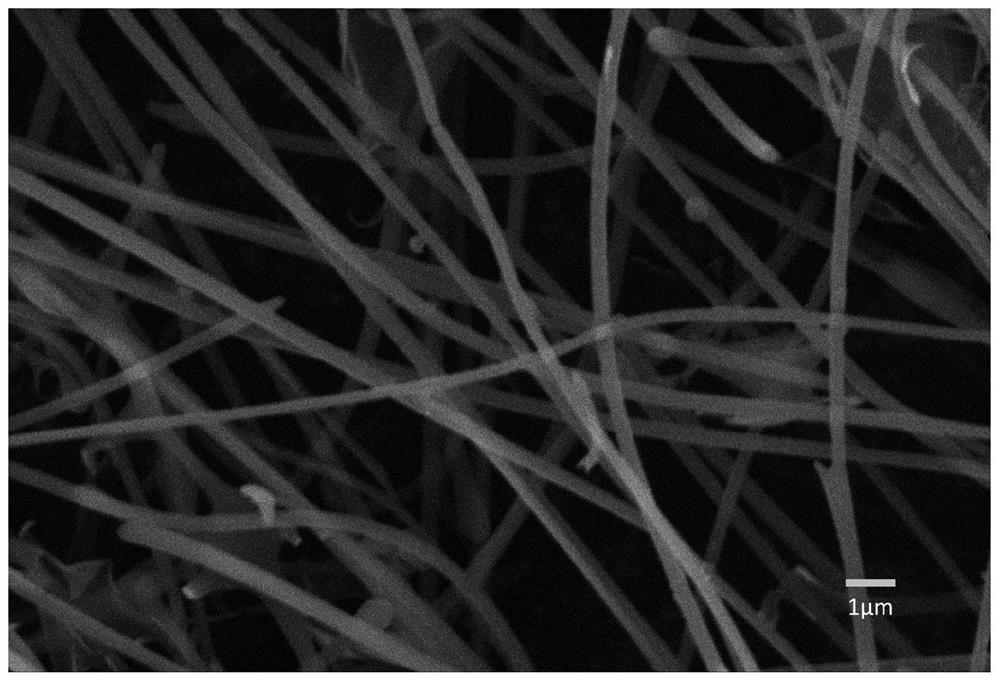

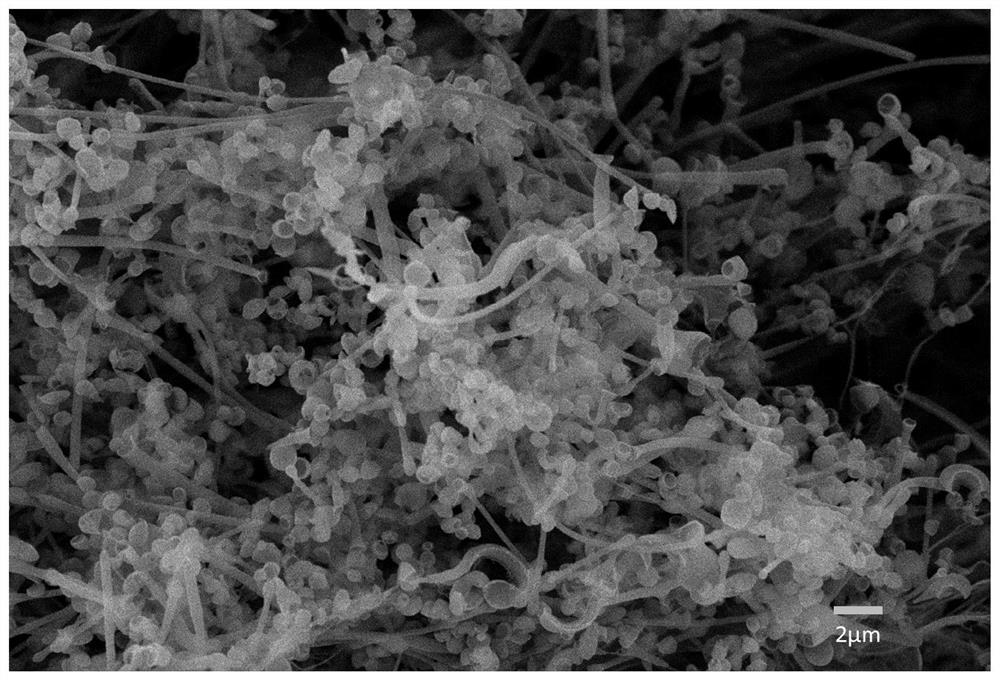

Image

Examples

Embodiment 1

[0030] A method for preparing lignin nanotubes from agricultural and forestry biomass raw materials, comprising the following steps:

[0031] (1) Disperse 100g of pulverized wheat straw in a sodium hydroxide solution with a mass concentration of 0.4%. The mass concentration of the biomass raw material in the sodium hydroxide solution is 1%. After adding tetrahydrofuran thereto, carry out ball milling, and the sodium hydroxide solution The volume ratio to tetrahydrofuran is 100:5, the ball milling speed is 600rpm, the ball milling time is 10h, and then centrifuged at 10000rpm for 5min to collect the supernatant;

[0032] (2) To the supernatant of step (1), dropwise add hydrochloric acid with a mass concentration of 0.4% at a rate of 200 μL / min until the solution is neutral, and then use a semipermeable membrane to perform dialysis for 48 hours to obtain lignin-containing nanoparticles. tube of solution.

Embodiment 2

[0034] A method for preparing lignin nanotubes from agricultural and forestry biomass raw materials, comprising the following steps:

[0035] (1) 100g of pulverized wheat straw material is dispersed in a sodium hydroxide solution with a mass concentration of 2%. The mass concentration of the biomass raw material in the sodium hydroxide solution is 3%, and polyethylene glycol with a molecular weight of 4000 is added thereto. Carry out ball milling afterward, the volume ratio of sodium hydroxide solution and polyethylene glycol is 100:10, and ball milling speed is 300rpm, and ball milling time is 8h, centrifuges 7min under the condition of 12000rpm then, collects supernatant;

[0036] (2) To the supernatant of step (1), dropwise add hydrochloric acid with a mass concentration of 0.4% at a rate of 500 μL / min until the solution is neutral, and then use a semipermeable membrane to perform dialysis for 24 hours to obtain lignin-containing nanoparticles. tube of solution.

Embodiment 3

[0038] A method for preparing lignin nanotubes from agricultural and forestry biomass raw materials, comprising the following steps:

[0039] (1) Dispersing 100g of pulverized corn stalks in a potassium hydroxide solution with a mass concentration of 3%, the biomass raw material in a potassium hydroxide solution with a mass concentration of 6%, adding dimethyl sulfoxide to it and then performing ball milling, The volume ratio of potassium hydroxide solution to dimethyl sulfoxide is 100:10, the ball milling speed is 500rpm, the ball milling time is 8h, then centrifuged at 12000rpm for 6min, and the supernatant is collected;

[0040] (2) To the supernatant of step (1), dropwise add hydrochloric acid with a mass concentration of 0.7% at a rate of 400 μL / min until the solution is neutral, and then use a semi-permeable membrane to perform dialysis for 3 hours to obtain lignin-containing nanoparticles. tube of solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com