Silicone acrylic resin coating as well as preparation method and application thereof

A silicone acrylic resin and coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high cost of functional silicone monomers or polymers, unfavorable industrial production, limited silicone oil content, etc., and achieve good hydrophobic anti-adhesion performance , controllable performance, and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 20 parts of lauryl methacrylate, 10 parts of methyl methacrylate, 1 part of trimethylolpropane trimethacrylate, 1 part of acrylic acid, 5 parts of silicone prepolymer and 2 parts of gamma-methacryloyl Dissolve oxypropyltrimethoxysilane in 30 parts of toluene, mix thoroughly, heat up to 100°C, add 0.01 part of initiator peroxydicarbonate-(2-ethylhexyl) ester, and perform free radical polymerization for 3 hours. Cool down, filter and discharge to obtain silicone acrylic resin.

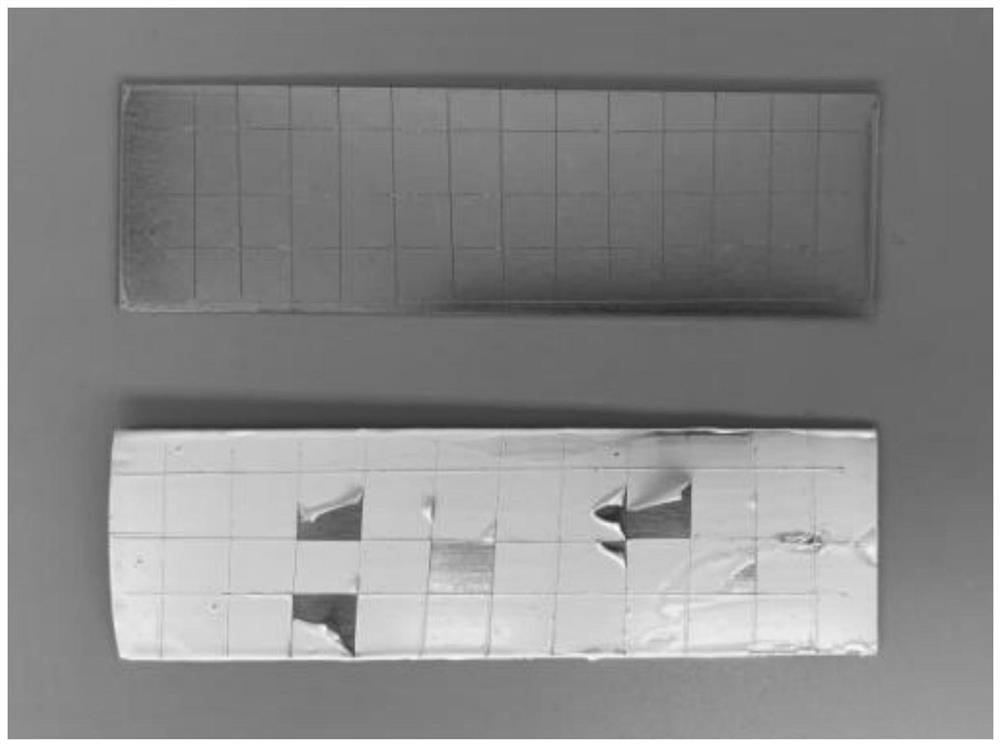

[0053] Coat the above-mentioned silicone acrylic resin on the tinplate sheet by at least one method of spin coating, dip coating, drip coating, brush coating, and spray coating, and test its coating film performance after coating and drying at room temperature for 3 hours. The performance results of various tests are shown in Table 1 .

[0054] The invention uses the national standard GB / T9286-88 cross-cut method to test the coating adhesion;

[0055] The present invention uses the national stan...

Embodiment 2

[0057] 20 parts of lauryl methacrylate, 10 parts of methyl methacrylate, 1 part of trimethylolpropane trimethacrylate, 2 parts of acrylic acid, 5 parts of silicone prepolymer and 2 parts of γ-methacryloyl Dissolve oxypropyltrimethoxysilane in 30 parts of toluene, mix thoroughly, heat up to 100°C, add 0.01 part of initiator peroxydicarbonate-(2-ethylhexyl) ester, and perform free radical polymerization for 3 hours. Cool down, filter and discharge to obtain silicone acrylic resin.

[0058] Coat the above-mentioned silicone acrylic resin on the tinplate sheet by at least one of spin coating, dip coating, drip coating, brush coating and spray coating. After the coating film is dried at room temperature for 3 hours, test its coating film performance. The test performance results are shown in the table 1.

[0059] The invention uses the national standard GB / T9286-88 cross-cut method to test the coating adhesion;

[0060] The present invention uses the national standard GB / T6739-19...

Embodiment 3

[0062] 20 parts of lauryl methacrylate, 10 parts of methyl methacrylate, 1 part of trimethylolpropane trimethacrylate, 3 parts of acrylic acid, 5 parts of silicone prepolymer and 2 parts of gamma-methacryloyl Dissolve oxypropyltrimethoxysilane in 30 parts of toluene, mix thoroughly, heat up to 100°C, add 0.01 part of initiator peroxydicarbonate-(2-ethylhexyl) ester, and perform free radical polymerization for 3 hours. Cool down, filter and discharge to obtain silicone acrylic resin.

[0063] Coat the above-mentioned silicone acrylic resin on the tinplate sheet by at least one of spin coating, dip coating, drip coating, brush coating and spray coating. After the coating film is dried at room temperature for 3 hours, test its coating film performance. The test performance results are shown in the table 1.

[0064] The invention uses the national standard GB / T9286-88 cross-cut method to test the coating adhesion;

[0065] The present invention uses the national standard GB / T673...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com