High-corrosion-resistance photovoltaic support and production process thereof

A photovoltaic support and corrosion-resistant technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation and other directions, can solve problems such as support blocking, reducing power generation efficiency, accelerating support corrosion, etc., to improve corrosion resistance and service life, Improved power generation efficiency and protection from rainwater erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

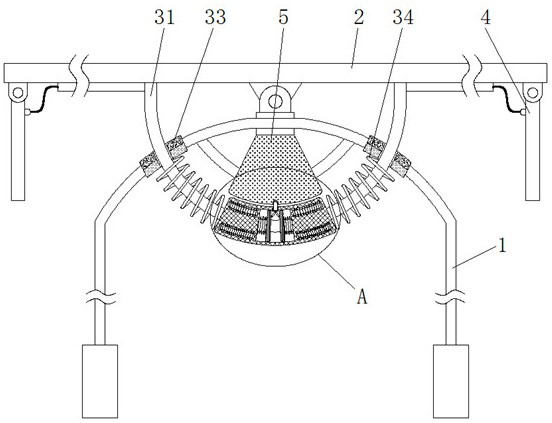

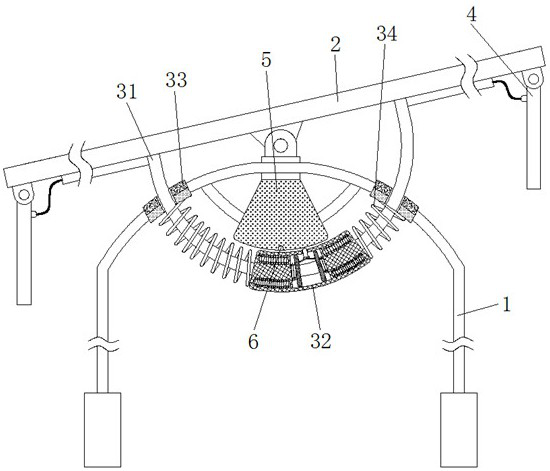

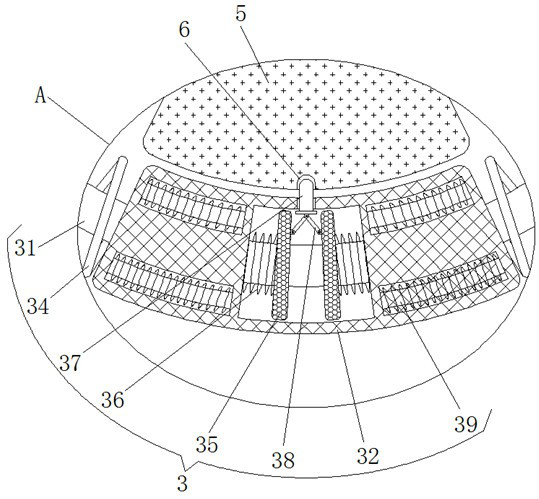

[0028] see Figure 1-3 , a high-corrosion-resistant photovoltaic bracket, including a self-adjusting mechanism 3, the self-adjusting mechanism 3 includes arc rods 31, mounting blocks 32 are fixedly installed between the bottoms of the arc rods 31, and the left and right sides of the peripheral mounting blocks 32 of the arc rods 31 Magnetic plates 33 are arranged on both sides, a spring 34 is fixedly connected between the magnetic plate 33 and the mounting block 32, and an iron ring 35 is slidingly connected to the inner part of the mounting block 32. There are two iron rings 35, which are symmetrically limited sliding It is connected to the inside of the middle part of the mounting block 32, and the transmission rod 38 is composed of two connecting rods, one end of which is rotationally connected with the bottom end of the limit post 37, and the other end is respectively rotationally connected with the adjacent sides of the two iron rings 35, so When the iron ring 35 moves tow...

Embodiment 2

[0030] A production process for a highly corrosion-resistant photovoltaic support, comprising the following steps:

[0031] S1. Forming of the bracket: cutting and bending the metal components, and welding them into metal components for assembling the photovoltaic bracket;

[0032] S2. Rough grinding: Grinding the weld scars on the surface of the metal components and removing the welding slag generated during the welding process;

[0033] S3. Fine grinding: put the metal components into a press-in dry sandblasting machine with a powder particle diameter of 2mm to treat the surface of the metal components;

[0034] S4. Pickling: Under the condition of 26°C-33°C, put the metal components into the pickling solution of hydrogen chloride and corrosion inhibitor to clean the metal components, and dry them after cleaning;

[0035] S5. Preparation of electroplating solution: Stir zinc oxide into a paste with a small amount of water, then add pure water and stir thoroughly, after stir...

Embodiment 3

[0040] see Figure 1-3, a high-corrosion-resistant photovoltaic bracket, including a self-adjusting mechanism 3, the self-adjusting mechanism 3 includes arc rods 31, mounting blocks 32 are fixedly installed between the bottoms of the arc rods 31, and the left and right sides of the peripheral mounting blocks 32 of the arc rods 31 Magnetic plates 33 are arranged on both sides, a spring 34 is fixedly connected between the magnetic plate 33 and the mounting block 32, and an iron ring 35 is slidingly connected to the inner part of the mounting block 32. There are two iron rings 35, which are symmetrically limited sliding It is connected to the inside of the middle part of the mounting block 32, and the transmission rod 38 is composed of two connecting rods, one end of which is rotationally connected with the bottom end of the limit post 37, and the other end is respectively rotationally connected with the adjacent sides of the two iron rings 35, so When the iron ring 35 moves towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com