Vinasse-based solid acid catalyst as well as preparation method and application thereof

A solid acid catalyst, distillers grains-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, applications, etc., can solve the problems of less application research, and achieve the effects of simple process flow, stable performance and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

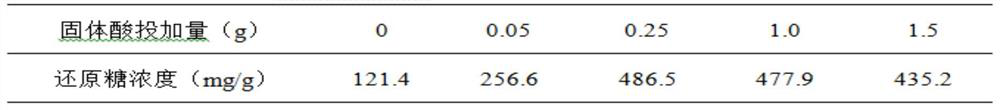

[0025] Example 1: The solid acid catalyzed hydrolysis reaction was carried out in a 50mL reactor (equipped with a polytetrafluoroethylene lining), and 0.5g of sorghum straw was added to the reactor, and 0g, 0.05g, 0.25g, 1.0g, 1.5g of solid acid catalyst, add distilled water to 50mL, stir evenly, cover tightly and seal, place in an oven at 100-160°C and heat for 1-5h. After the reaction is completed, the hydrolyzate is separated from the hydrolyzed residue and solid acid by suction filtration; the hydrolyzate is filtered through a filter membrane with a filter pore size of 0.22 μm, and the obtained filtrate is obtained by using 3,5-dinitrosalicylic acid ( DNS) method measures reducing sugar content, and the reducing sugar output result of calculation is as shown in table 1:

[0026] Table 1 Effect of distiller's grains-based solid acid dosage on sugar production by solid acid-catalyzed hydrolysis of sorghum straw

[0027]

[0028] Table 1

[0029] It can be seen from Tabl...

Embodiment 2

[0030] Embodiment 2: The distillers grains-based solid acid catalyst of the present invention is used to catalyze the hydrolysis of agricultural and forestry wastes to produce sugar, comprising the following steps:

[0031] The solid acid catalyzed hydrolysis reaction was carried out in a 50mL reactor (equipped with a polytetrafluoroethylene lining), and 0.5g fir chips were added to the reactor, and 0g, 0.05g, 0.25g, 1.0g, and 1.5g of solid acid were added respectively. Catalyst, add distilled water to 50mL, stir evenly, cover tightly and seal, place in an oven at 100-160°C and heat for 1-5h. After the reaction is finished, the hydrolyzate is separated from the hydrolyzed residue and solid acid by suction filtration; the hydrolyzate is filtered through a filter membrane with a filter pore size of 0.22 μm, and the obtained filtrate is obtained by using 3,5-dinitrosalicylic acid ( DNS) method measures reducing sugar content, and the reducing sugar output result of calculation is...

Embodiment 3

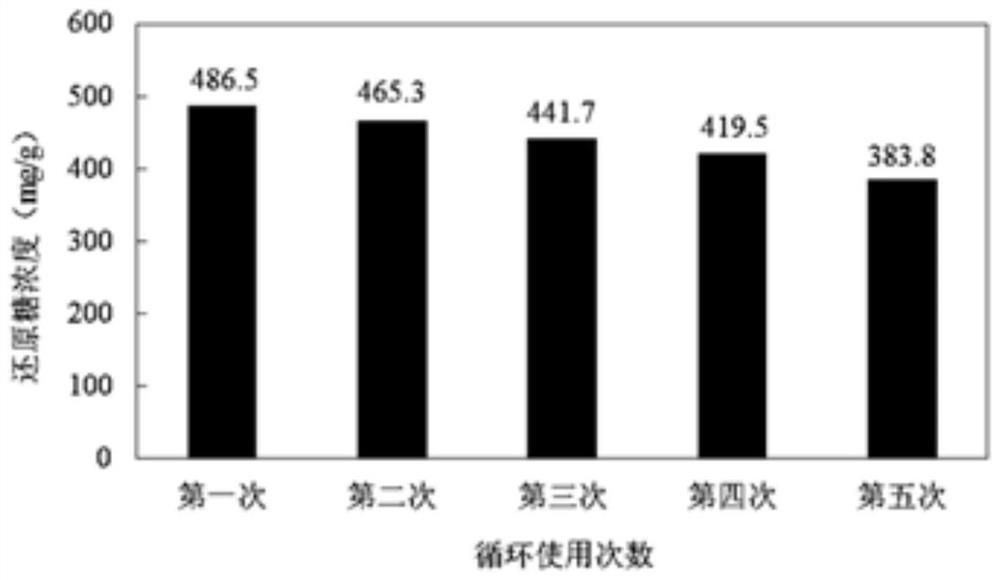

[0036] Example 3: The solid acid catalyzed hydrolysis reaction is carried out in a 50mL reactor (equipped with a polytetrafluoroethylene liner). Add 0.5g of sorghum stalks to the reactor, then add 0.25g of solid acid catalyst, add distilled water to 50mL, and stir Evenly, cover tightly and seal, place in an oven at 100-160°C and heat for 1-5 hours. After the reaction is over, the hydrolyzate is separated from the hydrolyzed residue and solid acid by suction filtration. The hydrolyzate is filtered through a filter membrane with a filter pore size of 0.22 μm. The obtained filtrate is 3,5-dinitrosalicylic acid (DNS ) method for the determination of reducing sugar content. According to the above steps, the separated solid acid is reused 4 times, and the reusability results of the solid acid are as follows: figure 2 shown.

[0037] Depend on figure 2 It can be seen that the concentration of reducing sugar in sorghum straw can reach 383.8 mg / g after 5 times of recycling of soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com