Preparation method and application of self-degradable leakage-proof plugging polymer composite material suitable for deepwater and ultra-deepwater drilling fluids

A technology of composite materials and polymers, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that cannot meet the protection requirements of deep water and ultra-deep water drilling reservoirs, leak prevention and plugging, retaining wall plugging and protection of reservoirs. Layer permeability is difficult to meet at the same time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

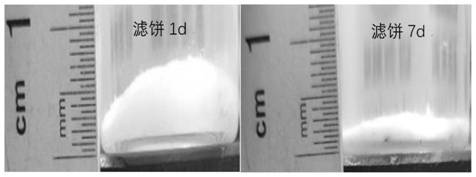

[0052] This example is to illustrate the self-degradation leakage prevention and plugging polymer composite material prepared by the method of the present invention.

[0053] Weigh 100 parts by weight of polymer resin particles in the reaction kettle according to the weight ratio, and gradually heat up to 175°C by heating in an oil bath, and then add 1.8 parts by weight of organic complexing accelerator and 12 parts by weight of inorganic weak acid under stirring conditions. Salt, 3.7 parts by weight of inorganic alkali metal hydroxide, stirred and reacted for 50 minutes; then, added 62 parts by weight of triazine melamine organic matter, stirred and reacted for 15 minutes; stopped heating and stirring, and the reactant naturally cooled to obtain off-white solid product , crushing the solid product to obtain self-degradation leak-proof plugging polymer composite materials with different particle sizes;

[0054] The polymer resin described therein contains the structural unit s...

Embodiment 2

[0064] This example is to illustrate the self-degradation leakage prevention and plugging polymer composite material prepared by the method of the present invention.

[0065] Weigh 100 parts by weight of polymer resin particles in the reaction kettle according to the weight ratio, gradually heat up to 175°C by heating in an oil bath, and then add 1.2 parts by weight of an organic complexing accelerator and 18 parts by weight of an inorganic weak acid under stirring conditions. Salt, 2.6 parts by weight of inorganic alkali metal hydroxide, stirred and reacted for 40 minutes; then, added 37 parts by weight of triazine melamine organic matter, stirred and reacted for 10 minutes; stopped heating and stirring, and the reactant naturally cooled to obtain off-white solid product , crushing the solid product to obtain self-degradation leak-proof plugging polymer composite materials with different particle sizes;

[0066] The polymer resin described therein contains the structural unit s...

Embodiment 3

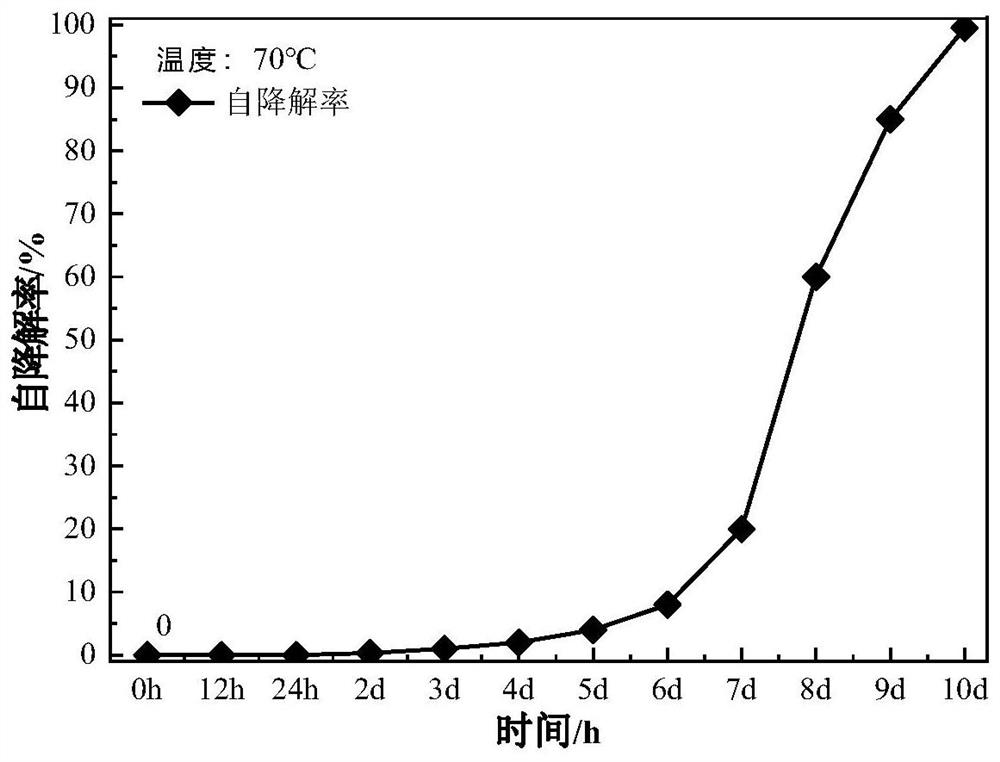

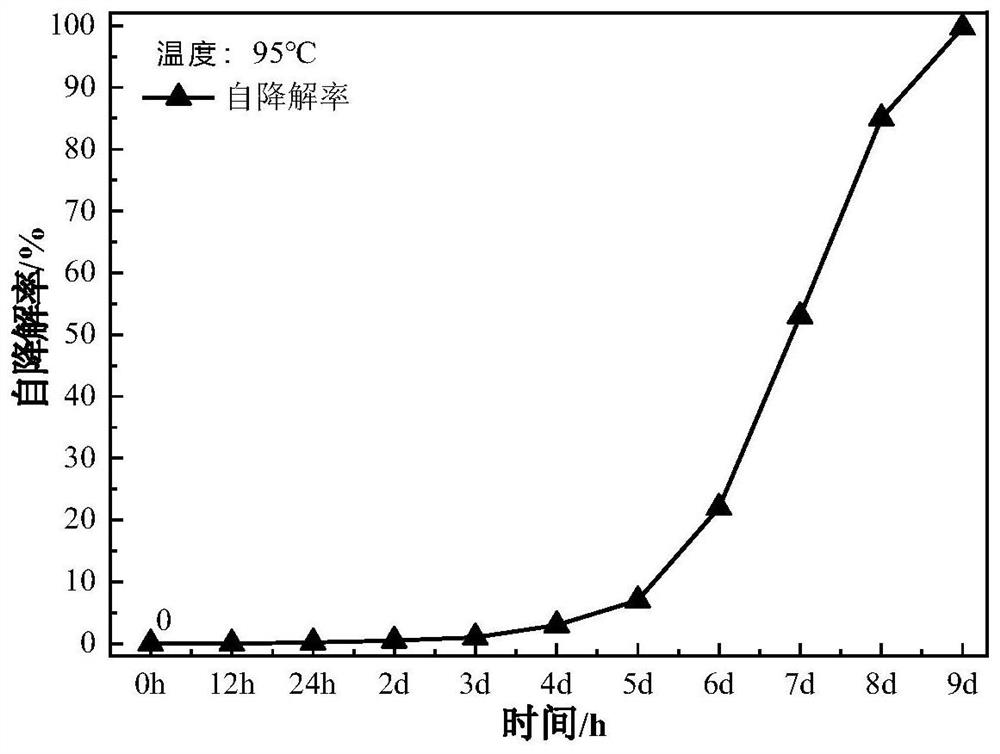

[0076] This example is to illustrate the self-degradation anti-leakage plugging polymer composite material prepared by the method of the present invention and its application, especially the application in deep water and ultra-deep water drilling fluid.

[0077] The specific composition of the deepwater and ultra-deepwater self-degradable drilling fluid system is: fresh water + 1.0% fluid loss reducer PF-FLOTROL + 0.3% PF-PLUS + 0.3% PF-XC + 0.7% anti-sudden lubricant PF-HLUB + 3.0% Strong inhibitor polyamine PF-UHIB + 2.5% coating agent PF-EZCARB + 5% KCl + 15% NaCl + 3.0% self-degradation leak-proof plugging polymer composite material S1.

[0078] Among them, fluid loss reducer PF-FLOTROL, PF-PLUS, PF-XC, anti-slagging lubricant PF-HLUB, strong inhibitor polyamine PF-UHIB, and coating agent PF-EZCARB were provided by China Oilfield Services Co., Ltd. supply.

[0079] As a result, the self-degradable drilling fluid system in deep water and ultra-deep water was prepared, ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com