Separation and purification method of active starfish peptide, active starfish peptide and application

A sea star, active technology, applied in the field of sea star peptide separation and purification, can solve the problems of large toxic and side reactions, poor selectivity, toxic and side effects, and achieve the effects of easy operation, strong targeting and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] As a preferred embodiment of the present invention, the separation and purification method of active starfish peptide comprises the following steps:

[0051] (a) Dissolve the crude starfish peptide in pure water, filter to obtain a starfish peptide sample, and refrigerate at -4°C for later use;

[0052](b) Put the swollen chromatography filler (including absolute ethanol in the preservation liquid), after standing and settling, discard the upper layer liquid and the floating chromatography filler, add an appropriate amount of ultrapure water, and repeat washing until the ethanol is completely remove;

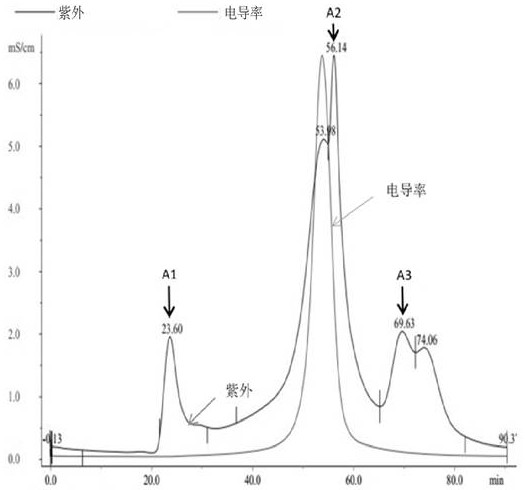

[0053] Connect the AKTA instrument, column and column packer, shake the chromatography filler evenly and pour it into the column packer quickly, after natural settlement for 24 hours, press the column with a mobile phase at a certain flow rate until the interface of the filler in the column no longer moves down , use BSA to detect column efficiency to check the packing e...

Embodiment 1

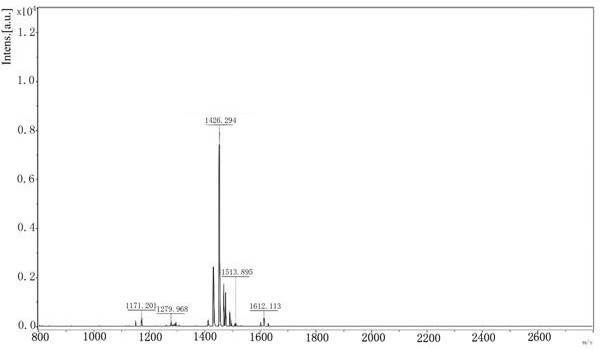

[0075] This embodiment provides a method for separation and purification of active starfish peptide, comprising the following steps:

[0076] (a) Wash the starfish with clean water, remove the viscera, cut it into pieces, discard as much water as possible, and weigh it. Add ultrapure water twice its mass to the shredded starfish body wall. Homogenize with a tissue homogenizer (22000rpm, 10min) to obtain starfish homogenate. Add 2 times the volume of PBS of the homogenate and a compound enzyme of 1% starfish mass (the compound enzyme is alkaline protease, papain, and trypsin prepared at an activity unit ratio of 3:4:4), and put the above homogenate at 50°C Enzymolysis was carried out in a constant temperature water bath for 10 hours, stirring continuously, and keeping the pH between 6.8 and 7.2.

[0077] After the enzymatic hydrolysis, three times the volume of 95% ethanol was added to the enzymatic hydrolysis solution, and it was placed in a refrigerator at 4°C for 6 hours. ...

experiment example 1

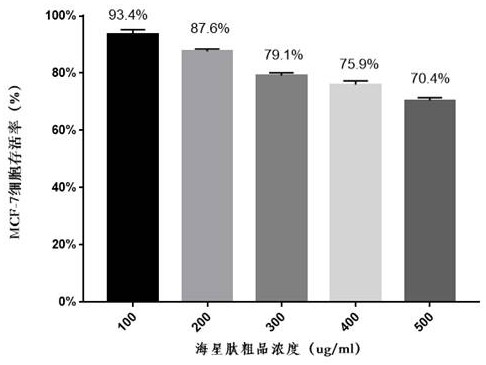

[0087] Experimental Example 1 Inhibition of proliferation of breast cancer cell MCF-7

[0088] (1) Crude starfish peptide

[0089] Accurately weigh 5 mg of the crude starfish peptide of Example 1, and dissolve it in 5 mL of DMEM medium containing 10% FBS (fetal bovine serum), wherein the final concentration of the starfish peptide crude product is 1 mg / mL. After being sterilized by filtration through a 0.22μm microporous membrane, it was used as the mother solution for anti-tumor activity test, and the other concentrations used were diluted from this concentration. Breast cancer cells MCF-7 were plated and cultured for 24 hours until they adhered to the wall. The starfish peptide anti-tumor activity test mother solution was diluted to 100 μg / mL, 200 μg / mL, 300 μg / mL, 400 μg / mL, and 500 μg / mL respectively. Six replicate wells were set up for each concentration. Aspirate the medium in the wells before adding the drug, and add 100 μL of the starfish peptide crude product soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com