Method and system for producing one or more olefins

A technology for alkenes, alkynes, used in the field of production or multiple alkenes and systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

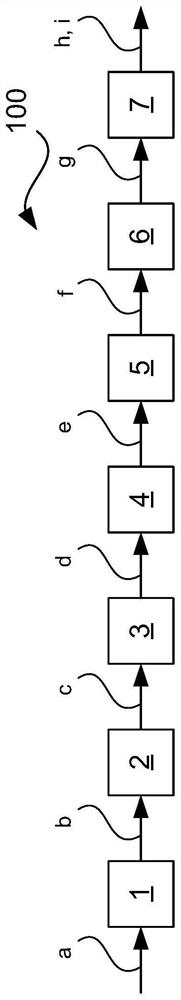

[0060] figure 1 A method, generally designated 100 , according to a particularly preferred embodiment of the invention is illustrated. The explanations about the method 100 are also applicable to the corresponding device, wherein figure 1 The process steps shown are carried out by corresponding plant components.

[0061] In process 100, a reaction feed comprising oxygen and one or more paraffins is formed and undergoes oxidative dehydrogenation 1 in material stream a. The process gas formed in the oxidative dehydrogenation is at least partially fed to the condensation separation 2 in which, for example, water and acetic acid are separated condensately. The corresponding process gas or part thereof is fed to the condensation separation in the form of process gas stream b.

[0062] The process gas removed from the condensation separation and depleted of water and possibly other components is fed in the form of process gas stream c to the process gas compressor or feed gas com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com