A tail gas treatment method for preparing dl-homocysteine

A technology for tail gas treatment and homocystine, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of gas emission, no fundamental solution, incomplete tail gas treatment, etc., and achieve uniform exhaust gas contact and removal. rate enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

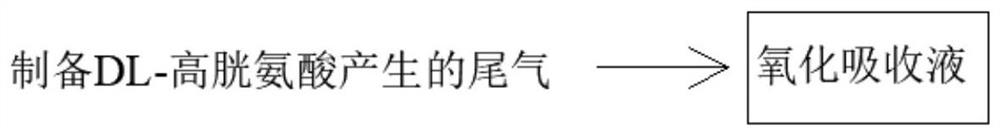

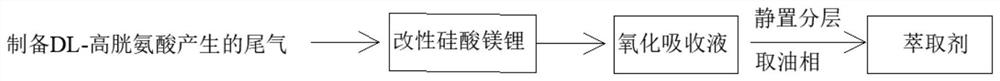

Method used

Image

Examples

Embodiment 1

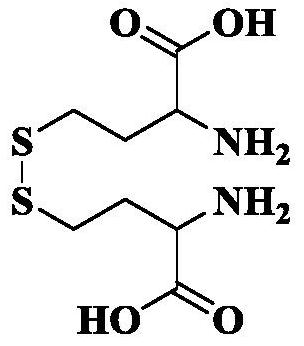

[0032] Add 50.0 g of DL-methionine and 60.0 g of water into a 500 mL four-neck flask, stir at room temperature, and slowly add 80.0 g of concentrated sulfuric acid dropwise to the system. After the addition, the temperature of the system is raised to 125°C, the system adopts a slight negative pressure, and a tail gas absorption device is installed in the middle, and the device is equipped with 5.0% mass concentration of hydrogen peroxide, and the whole process is reacted for 8 hours. After the reaction, detect the components in the absorption solution.

Embodiment 2

[0034] Add 50.0 g of DL-methionine and 60.0 g of water into a 500 mL four-neck flask, stir at room temperature, and slowly add 80.0 g of concentrated sulfuric acid dropwise to the system. After the addition, the temperature of the system is raised to 125°C, the system adopts a slight negative pressure, and a tail gas absorption device is installed in the middle, and a sodium hypochlorite solution with a mass concentration of 15.0% is installed in the device, and the whole process is reacted for 8 hours. After the reaction, detect the components in the absorption solution.

Embodiment 3

[0036] Add 50.0 g of DL-methionine and 60.0 g of water into a 500 mL four-neck flask, stir at room temperature, and slowly add 80.0 g of concentrated sulfuric acid dropwise to the system. After adding, the temperature of the system is raised to 125°C, the system adopts a slight negative pressure, and an exhaust gas absorption device is installed in the middle. The device is equipped with 15.0% mass concentration of sodium hypochlorite solution and 5.0% mass concentration of hydrogen peroxide, and the whole process is reacted for 8 hours. After the reaction, detect the components in the absorption solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com