High-performance diamond wire dispersing agent, preparation method and mixing device thereof

A technology of mixing device and diamond wire, applied in the field of diamond wire, can solve the problems of agglomeration of dispersant, and achieve the effect of good dispersion performance, increase in quantity and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

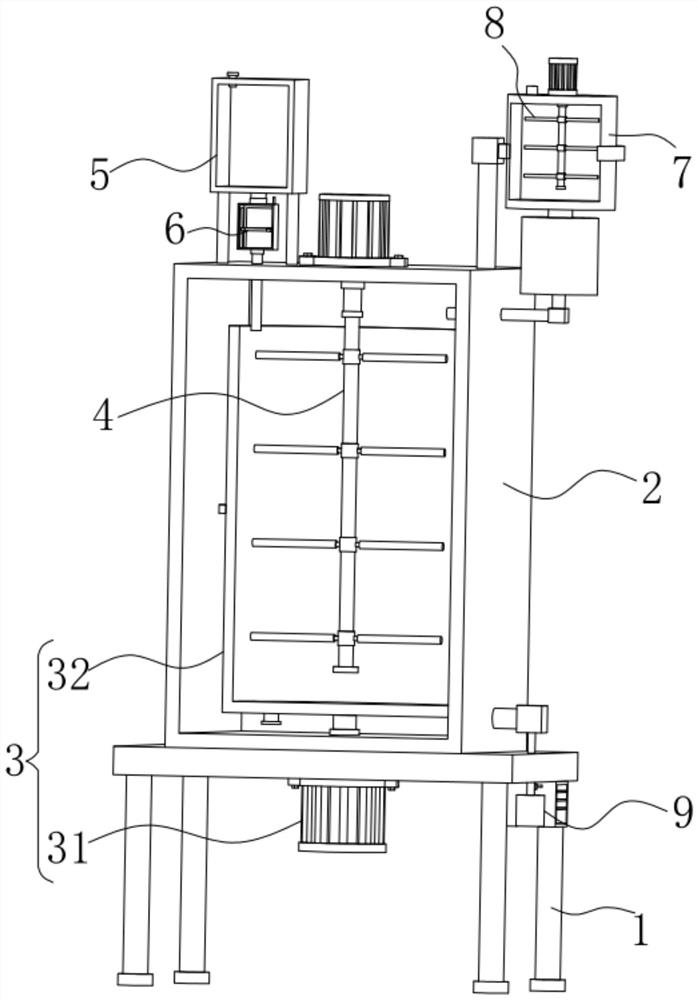

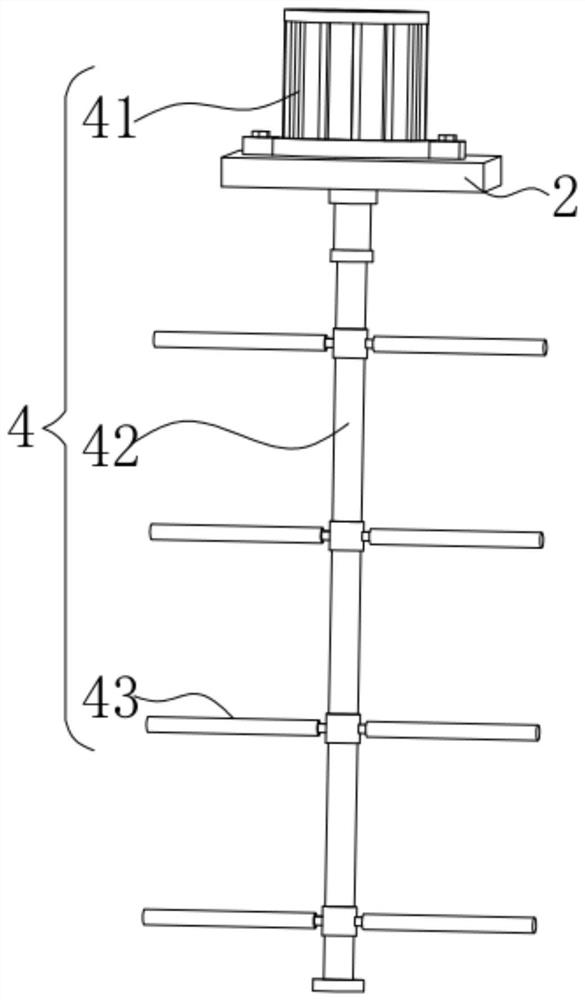

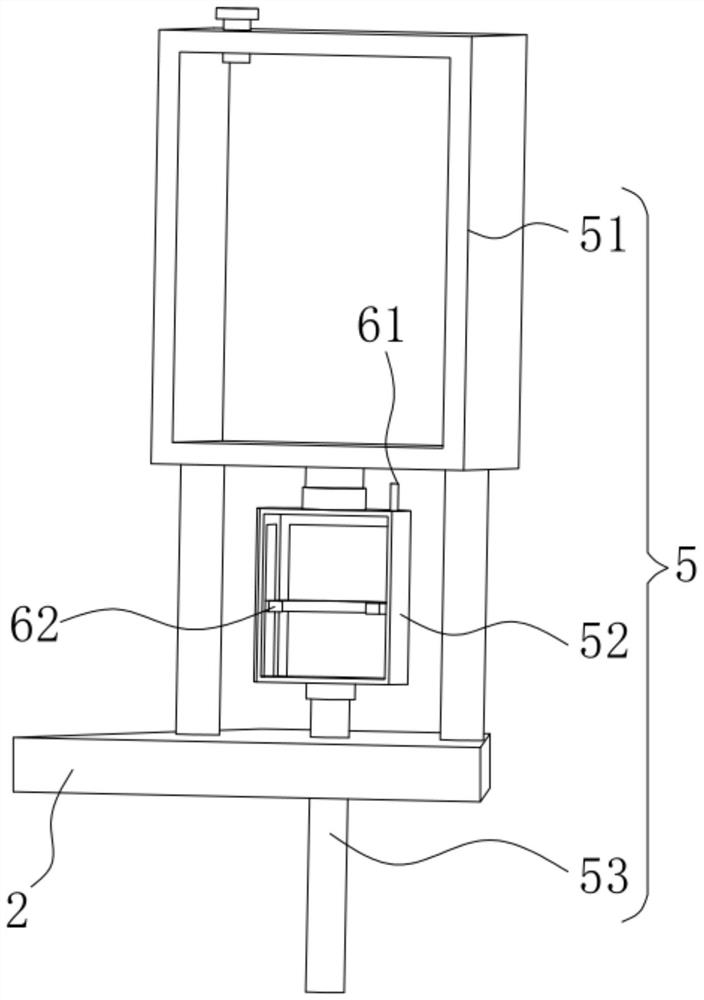

Image

Examples

no. 1 example

[0049] A high-performance diamond wire dispersant, consisting of the following raw materials in parts by weight:

[0050] Methacrylic acid, acrylamide, initiator, water, higher alcohol and oleic acid acyl, said methacrylic acid 10-70 parts, acrylamide 10-50 parts, initiator 5-20 parts, water 100 parts, higher alcohol 3- 8 parts, oleic acid acyl 2-5 parts.

[0051] Consists of the following raw materials in parts by weight:

[0052] 50 parts of methacrylic acid, 10 parts of acrylamide, 6 parts of initiator, 27 parts of water, 4 parts of higher alcohol, 3 parts of oleic acid.

[0053] A preparation method of high-performance diamond wire dispersant, comprising the following steps:

[0054] S1, heating and melting 50 parts of methacrylic acid in a melting device according to the proportion;

[0055] S2. During the melting process of methacrylic acid, 10 parts of acrylamide and 27 parts of water are placed inside the stirring device for mixing;

[0056] S3. After the methacryl...

no. 2 example

[0065] A high-performance diamond wire dispersant, consisting of the following raw materials in parts by weight:

[0066] Methacrylic acid, acrylamide, initiator, water, higher alcohol and oleic acid acyl, said methacrylic acid 10-70 parts, acrylamide 10-50 parts, initiator 5-20 parts, water 100 parts, higher alcohol 3- 8 parts, oleic acid acyl 2-5 parts.

[0067] Consists of the following raw materials in parts by weight:

[0068] 40 parts of methacrylic acid, 20 parts of acrylamide, 9 parts of initiator, 24 parts of water, 3 parts of higher alcohol, 4 parts of oleic acid.

[0069] A preparation method of high-performance diamond wire dispersant, comprising the following steps:

[0070] S1, 40 parts of methacrylic acid is heated and melted in the melting device according to the proportion;

[0071] S2. During the process of melting methacrylic acid, place 20 parts of acrylamide and 24 parts of water in the stirring device for mixing;

[0072] S3. After the melting of meth...

no. 3 example

[0078] A high-performance diamond wire dispersant, consisting of the following raw materials in parts by weight:

[0079] Methacrylic acid, acrylamide, initiator, water, higher alcohol and oleic acid acyl, said methacrylic acid 10-70 parts, acrylamide 10-50 parts, initiator 5-20 parts, water 100 parts, higher alcohol 3- 8 parts, oleic acid acyl 2-5 parts.

[0080] Consists of the following raw materials in parts by weight:

[0081] 60 parts of methacrylic acid, 10 parts of acrylamide, 5 parts of initiator, 20 parts of water, 3 parts of higher alcohol, 2 parts of oleic acid.

[0082] A preparation method of high-performance diamond wire dispersant, comprising the following steps:

[0083] S1, 60 parts of methacrylic acid is heated and melted in the melting device according to the proportion;

[0084] S2. During the process of melting methacrylic acid, place 10 parts of acrylamide and 20 parts of water in the stirring device for mixing;

[0085] S3. After the methacrylic aci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap