Preparation method of porous carbon loaded zero-valent iron composite material

A composite material, zero-valent iron technology, applied in the field of water treatment, can solve the problems of difficult to achieve industrialized production, high production cost of zero-valent iron, and the preparation process is not environmentally friendly, and achieves green environmental protection cost, large specific surface area, good large-scale The effect of industrial production and application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

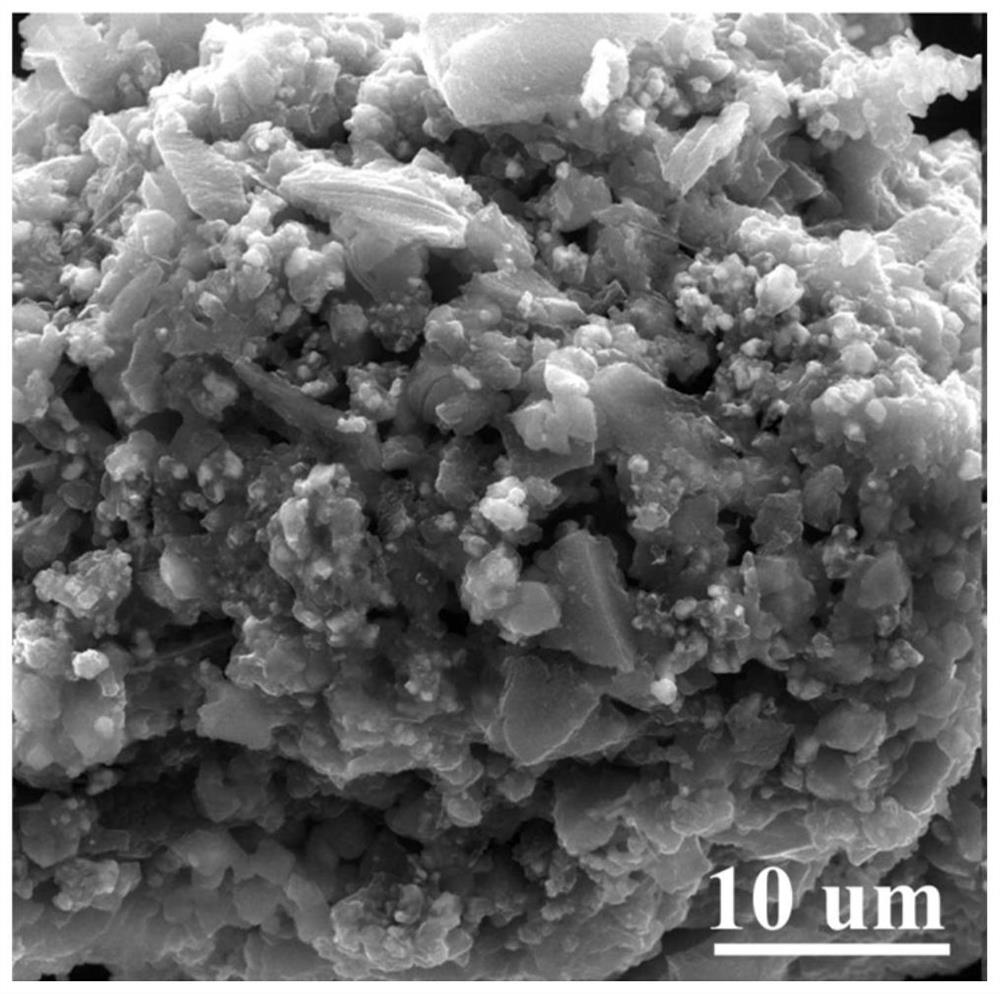

[0051] This embodiment provides the preparation of a porous carbon composite material supported zero-valent iron, comprising the steps of:

[0052] (1) The neodymium iron slag dried 3 hours at 100 deg.] C, allowed to cool; 3 hours using ball milling;

[0053] (2) Weigh 1.6g of neodymium iron slag, as a beaker, 1.8g of activated charcoal was added, which made the magnet iron slag (as Fe 2 O 3 Calculated as moles) and activated carbon molar ratio of 1:15, was added 5.4g of KOH, KOH and that the mass ratio of activated carbon is 3: 1, 100mL anhydrous ethanol was added, the agitator speed was 300r / min, stirring 30min;

[0054] (3) The beaker mouth sealed, placed in an ultrasonic cleaning machine power is 1200W, the ultrasonic for 2 hours at room temperature; dried at 80 ℃ 12 hours;

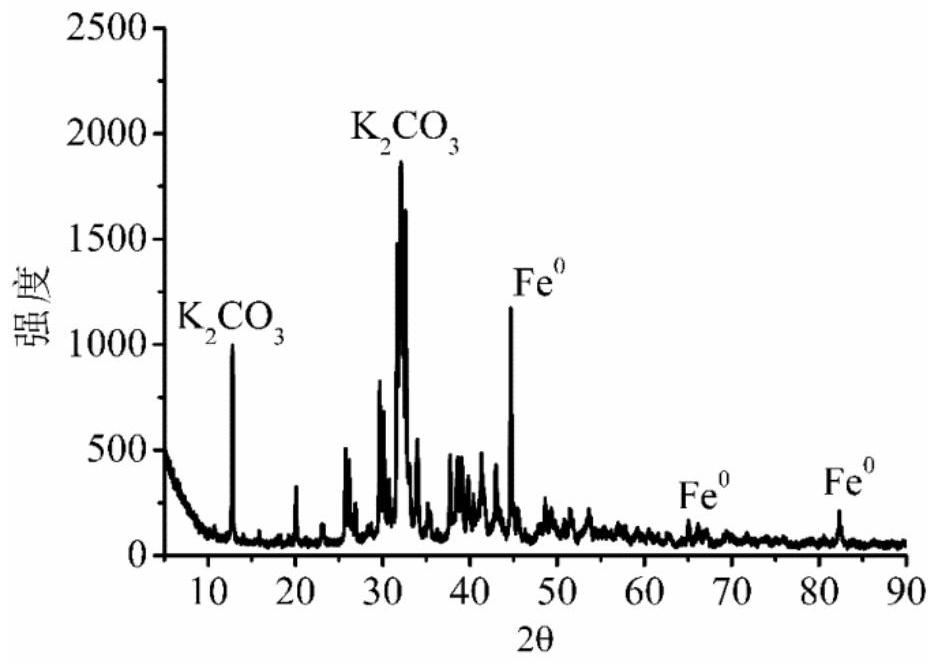

[0055] (4) grinding the resulting solid was dried, placed in a covered crucible at a heating rate and conditions min 10 ℃ / 900 ℃ the calcined one hour, the mesoporous carbon composite material load ZVI...

Embodiment 2

[0058] This embodiment provides the preparation of a porous carbon composite material supported zero-valent iron, comprising the steps of:

[0059] (1) The neodymium iron slag dried 3 hours at 100 deg.] C, allowed to cool; 3 hours using ball milling;

[0060] (2) Weigh 1.6g of neodymium iron slag, as a beaker, 1.8g of activated charcoal was added, which made the magnet iron slag (as Fe 2 O 3 Calculated as moles) and activated carbon molar ratio of 1:15, was added 1.8g of KOH, KOH and the activated carbon mass ratio is 1: 1, 100mL anhydrous ethanol was added, the agitator speed was 300r / min, stirring 30min;

[0061] (3) The beaker mouth sealed, placed in an ultrasonic cleaning machine power is 1200W, the ultrasonic for 2 hours at room temperature; dried at 80 ℃ 12 hours;

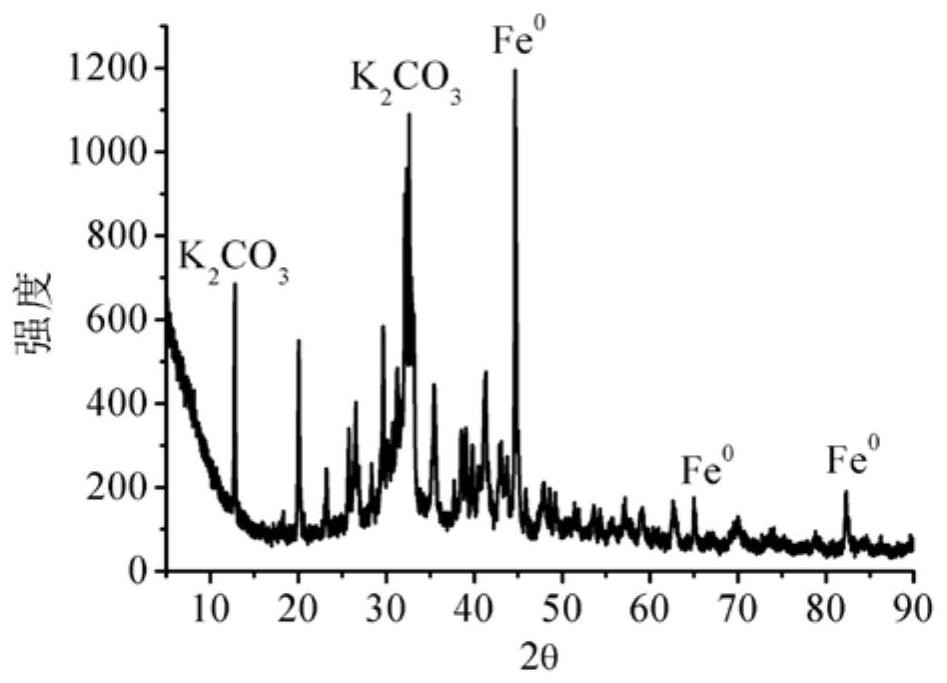

[0062] (4) grinding the resulting solid was dried, placed in a covered crucible at a heating rate and conditions min 10 ℃ / 900 ℃ the calcined one hour, the mesoporous carbon composite material load ZVI i.e. ma...

Embodiment 3

[0065] This embodiment provides the preparation of a porous carbon composite material supported zero-valent iron, comprising the steps of:

[0066] (1) The neodymium iron slag dried 3 hours at 100 deg.] C, allowed to cool; 3 hours using ball milling;

[0067] (2) Weigh 1.6g of neodymium iron slag, as a beaker, 1.8g of activated charcoal was added, which made the magnet iron slag (as Fe 2 O 3 Calculated as moles) and activated carbon molar ratio of 1:15, was added 0.6g of KOH, KOH and that the mass ratio of activated carbon was 1: 3, 100mL anhydrous ethanol was added, the stirrer speed set to 300r / min, stirring 30min;

[0068] (3) The beaker mouth sealed, placed in an ultrasonic cleaning machine power is 1200W, the ultrasonic for 2 hours at room temperature; dried at 80 ℃ 12 hours;

[0069] (4) grinding the resulting solid was dried, placed in a covered crucible at a heating rate and conditions min 10 ℃ / 900 ℃ the calcined one hour, the mesoporous carbon composite material load ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com