Magnesium-containing water-soluble omega-3 fatty acid

A water-soluble, omega technology, applied in the direction of organic active ingredients, carboxylic acid amide preparation, medical preparations containing active ingredients, etc., can solve the problems of single function, difficult modification, harsh modification conditions and reagents, etc., to achieve Growth-promoting, absorption-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

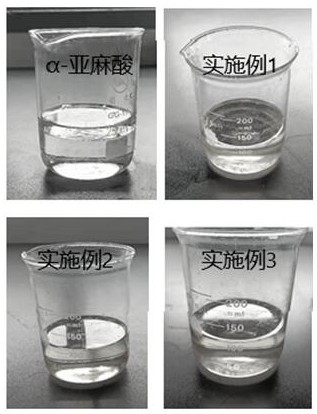

Examples

Embodiment 1

[0041] Step (1) parts by weight 10 parts by alanine weighed, 5 parts of magnesium carbonate and 150 parts of water;

[0042] Step (2) alanine, magnesium carbonate, and water A solution was prepared by mixing, adjusting the PH value of 3, and the mixed solution A were added to the reactor with a stirring function, a stirrer speed of 300r / min, during the reaction continued stirring, the reactor temperature was set to 80 ℃, reaction time IH, cooling filtration, and the filtrate was distilled water was removed with a rotary evaporator, to give a crude product, and the crude product was purified by column chromatography, and finally dried in vacuo to give alanine magnesium chelation.

[0043] Step (3) parts by weight 10 parts of a chelate of alanine weighed magnesium, 10 parts of acid, 50 parts of benzophenone and 3 parts of water, and mixed to prepare a mixed solution B, B into the mixed solution with stirring to function of reactor, stirrer speed of 200r / min, the stirring was con...

Embodiment 2

[0046] Step (1) parts by weight of alanine weighed 20 parts, 200 parts of magnesium carbonate and 15 parts of water.

[0047] Step (2) alanine, magnesium carbonate, and water A solution was prepared by mixing, adjusting the PH value of 5, and the mixed solution A were added to the reaction kettle equipped with a stirring function, a stirrer speed of 500r / min, during the reaction continued stirring, the reactor temperature was set to 100 deg.] C, the reaction time was 2h, cooling filtration, and the filtrate was distilled water was removed with a rotary evaporator, to give a crude product, and the crude product was purified by column chromatography, and finally dried in vacuo to give alanine magnesium chelation.

[0048] Step (3) 20 parts by weight of the alanine chelate magnesium, 20 parts of cinnamic acid, 100 parts of dibenzophen, 100 parts of water, and mix the mixed solution B, and mix the mixed solution B into the mixture. In the reactor of the function, the mixer speed is 50...

Embodiment 3

[0051] Step (1) Take 15 parts by weight of mass, 10 parts of magnesium carbonate and 180 water.

[0052] Step (2) Prepare the alanine, magnesium carbonate and water, adjusted the pH of 4, and put the mixed solution A into the reaction kettle with stirring function, the mixer rotation speed is 400R / min, the reaction process Continuously stirring, the temperature of the reaction kettage was set to 90 ° C, the reaction time was 1.5 h, cooled to remove the filtration, and the filtrate was removed by the rotary evaporator to obtain a crude product, and then the crude product was separated by column chromatography. Alanine chelating magnesium was obtained.

[0053] Step (3) Take 15 parts by weight of the alanine chelate magnesium, 15 parts of cinnamic acid, 4 parts of dibenzophen and 70 parts of water, and mix the mixed solution B, and the mixed solution B is put into charge with stirring. In the reactor of the function, the mixer speed is 300r / min, and the reaction is continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com