Nanoscale red liquid disperse dye and preparation method thereof

A liquid disperse dye and liquid dye technology, applied in the field of nano-scale red liquid disperse dye and its preparation, can solve the problems of high energy consumption of nano-processing, affecting storage stability, affecting dyeing performance, etc. Environmental protection indicators, easy to large-scale industrial production, high effect of no-wash soaping fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

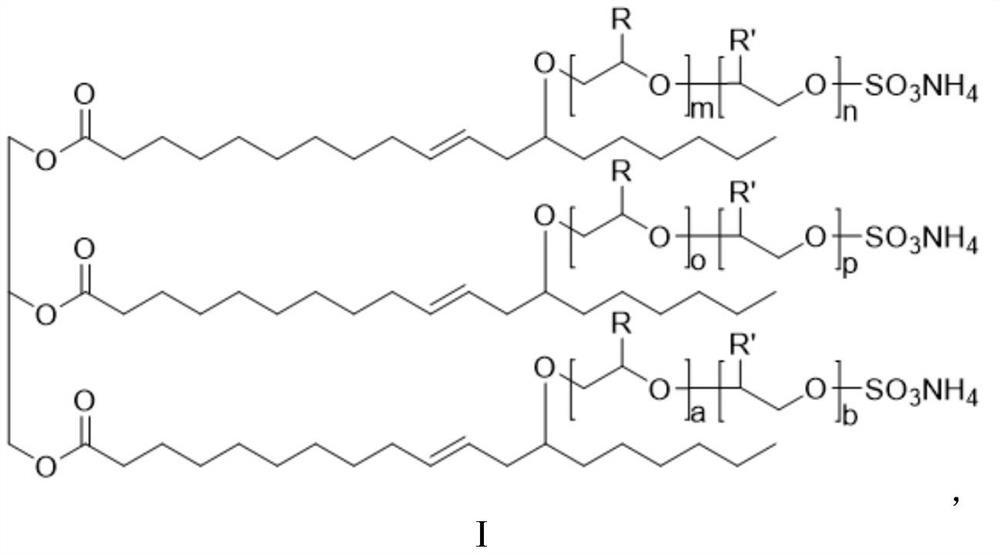

Method used

Image

Examples

Embodiment 1-7

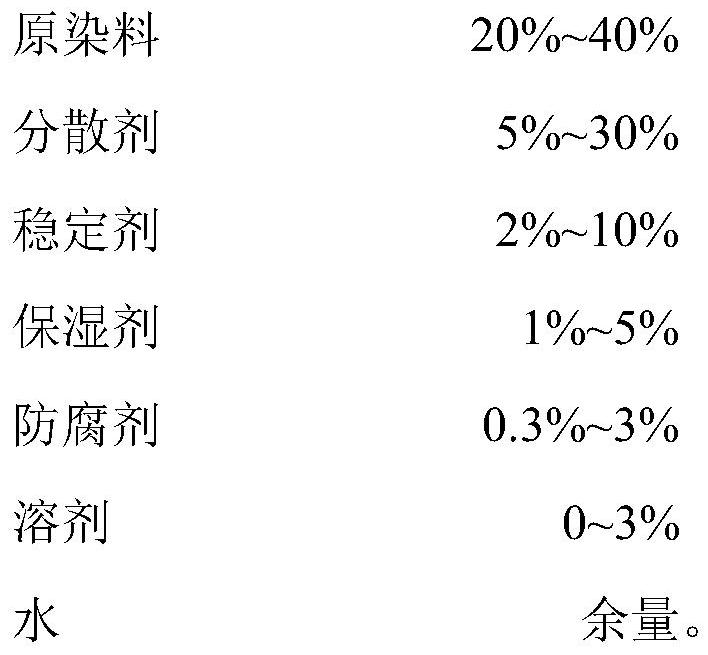

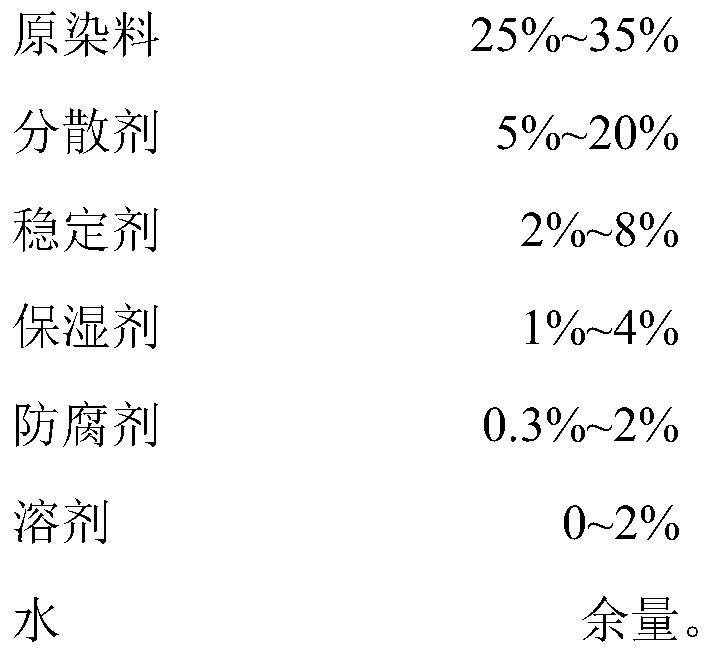

[0037] According to the dye formula in Table 1 (the balance is water), make nano-scale red liquid disperse dyes.

[0038] Table 1: the formula table of each embodiment (consumption is all by weight percentage)

[0039]

[0040]

[0041] The preparation process is as follows:

[0042] Dye crystal transformation technology: add wetting agent and dispersant to the water dispersion system of the original dye, and disperse and stir at 50-80°C for 1-2 hours to realize the crystal transformation of the dye.

[0043] Nano-technology: Put 60g of disperse dye filter cake after crystallization (dried) and 60g of water into a high-speed disperser for beating at a speed of 3000-5000r / min for 20min, filter it with cheesecloth and add it to the nanoscale dynamic separation Grinder, add the corresponding proportion of dispersant, supplement the corresponding proportion of water, grind for 2 to 5 hours at a speed of 3000r / min, the test particle size D09 is below 200 nanometers, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com