Medium-phase microemulsion as well as preparation process and application thereof

A technology of microemulsion and additives, which is applied in the field of mesophase microemulsion and its preparation process and application, can solve the problems that the influence of microemulsion oil recovery rate needs to be improved, and achieve enhanced oil recovery rate and enhanced oil recovery rate , high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

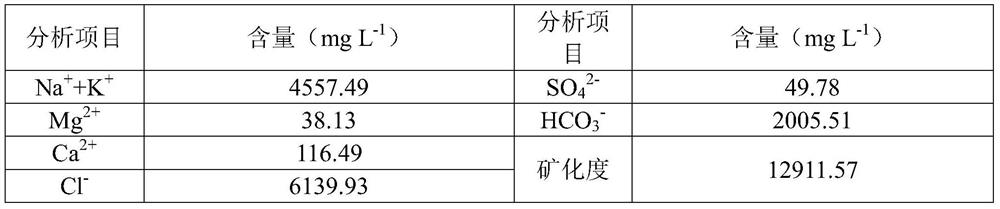

[0041] A kind of medium phase microemulsion, according to percentage by weight, comprises following components: 0.35% sodium dodecylbenzobicyclohexane sulfonate, 0.2% sodium dodecyl alcohol polyoxyethylene polyoxypropylene sulfonate (N= 20, M=20), 0.03% polyoxyethylene sorbitan fatty acid ester (CAS: 9005-66-7, Jiangsu Haian Petrochemical Plant), 0.001% glutaraldehyde and oil recovery reinjection water (remainder).

[0042] The preparation process of the medium-phase microemulsion comprises the following steps: adding glutaraldehyde to the oil recovery reinjection water, adding sodium dodecylbenzobicyclohexane sulfonate, sodium dodecyl polyoxypropylene sulfonate and polyoxygen Ethylene sorbitan fatty acid ester, mixed evenly, ready.

Embodiment 2

[0044] In addition to replacing sodium dodecylbenzobicyclohexanesulfonate with sodium tetradecylbenzobicyclohexanesulfonate (60%), sodium tetradecylacenaphthylsulfonate (30%), tetradecane Except the mixture of sodium biphenyl sulfonate (10%), keep the gross mass of main agent constant, all the other are identical with embodiment 1.

Embodiment 3

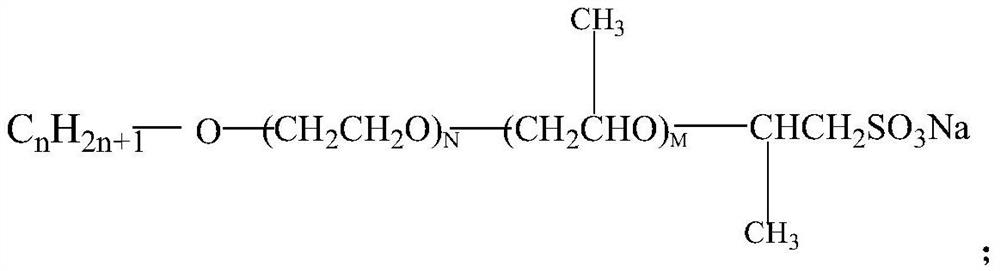

[0046]Except sodium lauryl alcohol polyoxyethylene polyoxypropylene sulfonate (N=20, M=20) is replaced by fatty alcohol polyoxyethylene polyoxypropylene sodium sulfonate, wherein n=12, N=15, M=12, All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com