Ultrathin bionic forest-shaped wick structure with high capillary performance and preparation method thereof

A technology of liquid-absorbing core and woods, which is applied in the field of ultra-thin bionic forest-like liquid-absorbing core structure and its preparation, can solve the problems of low porosity, low capillary performance, and heavy weight, and achieve reduced resistance, excellent capillary performance, The effect of high capillary performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

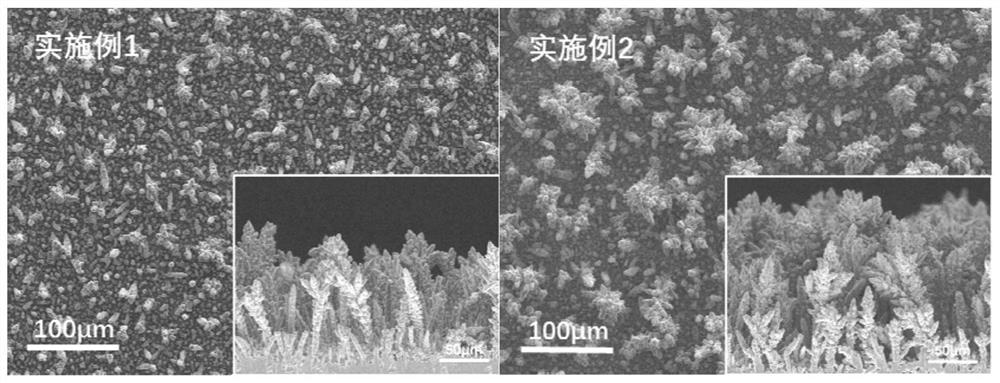

[0024] Example 1: Preparation of ultra-thin bionic forest-like liquid-absorbent core structure

[0025] (1) Sample pretreatment: The cathode is made of red copper foil, which is washed with acetone, ethanol, and deionized water in order to remove surface oil and oxide layers, and then dried for later use.

[0026] (2) Copper dendrite deposition: at a ratio of 0.7 M CuSO 4 and 0.75 M H 2 SO 4 In the electrolyte, keep the current growth rate at 0.67-1.33 mA / cm 2 / s, deposited for 160 s, and the obtained samples were washed and dried.

[0027] (3) Carry out high-temperature sintering treatment under the condition of reducing protective atmosphere to further enhance the mechanical strength of the sample, and prepare an ultra-thin bionic forest-like liquid-absorbent core structure.

Embodiment 2

[0028] Example 2: Preparation of ultra-thin bionic forest-like liquid-absorbent core structure

[0029] (1) Sample pretreatment: The cathode is made of red copper foil, which is washed with acetone, ethanol, and deionized water in order to remove surface oil and oxide layers, and then dried for later use.

[0030] (2) Copper dendrite deposition: at a ratio of 0.7 M CuSO 4 and 0.75 M H 2 SO 4 In the electrolyte, keep the current growth rate at 0.67-1.33 mA / cm 2 / s, deposited for 220 s, and the obtained samples were washed and dried.

[0031] (3) Carry out high-temperature sintering treatment under the condition of reducing protective atmosphere to further enhance the mechanical strength of the sample, and prepare an ultra-thin bionic forest-like liquid-absorbent core structure.

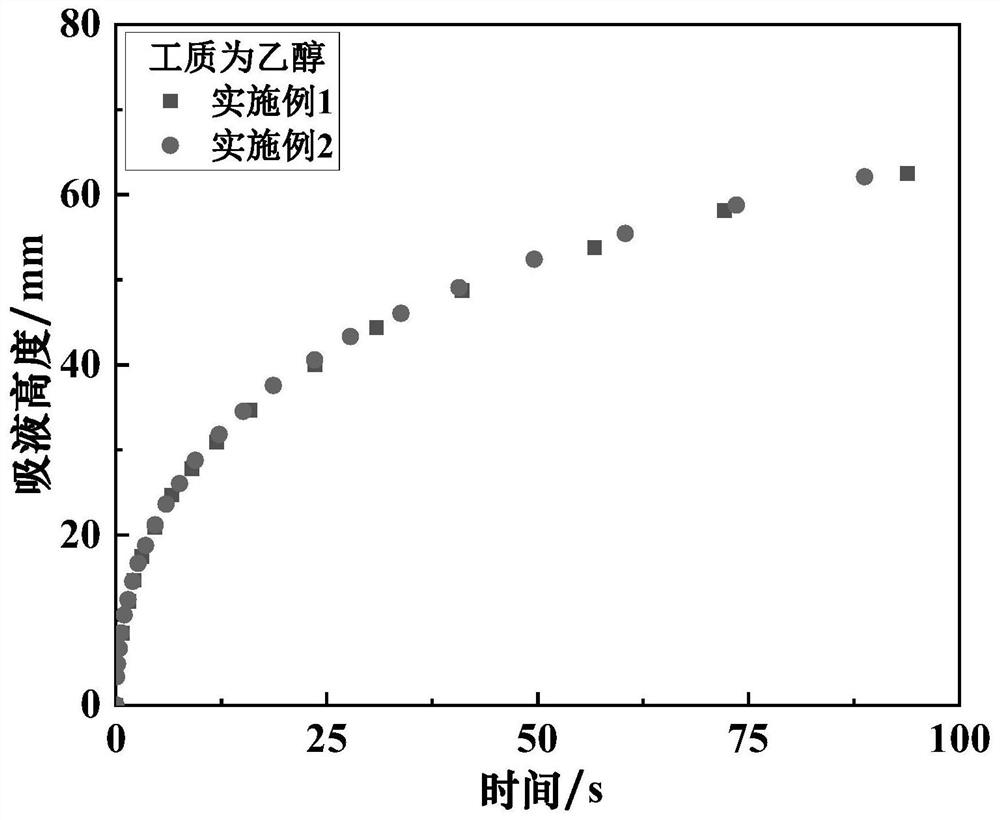

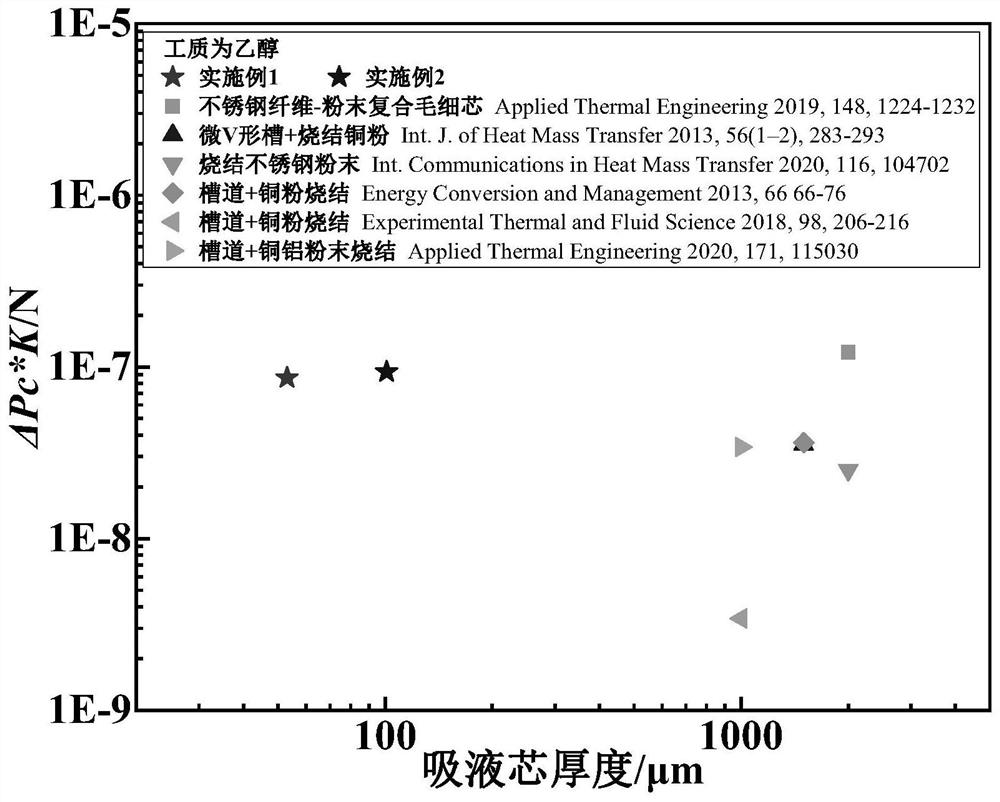

[0032] As shown in Table 1, when the thickness of the forest-like structure sample prepared by the present invention is only 53 μm and 101 μm, the porosity is as high as 84%, 87%, which is much hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com