Laser spot welding micro-welding spot quality detection device and method based on laser ultrasound

A laser spot welding and detection device technology, which is applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, material analysis through optical means, etc., can solve problems such as inability to apply complex shape structural parts detection, low efficiency, etc. , to achieve intuitive and reliable detection results, broad application prospects, and fast scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

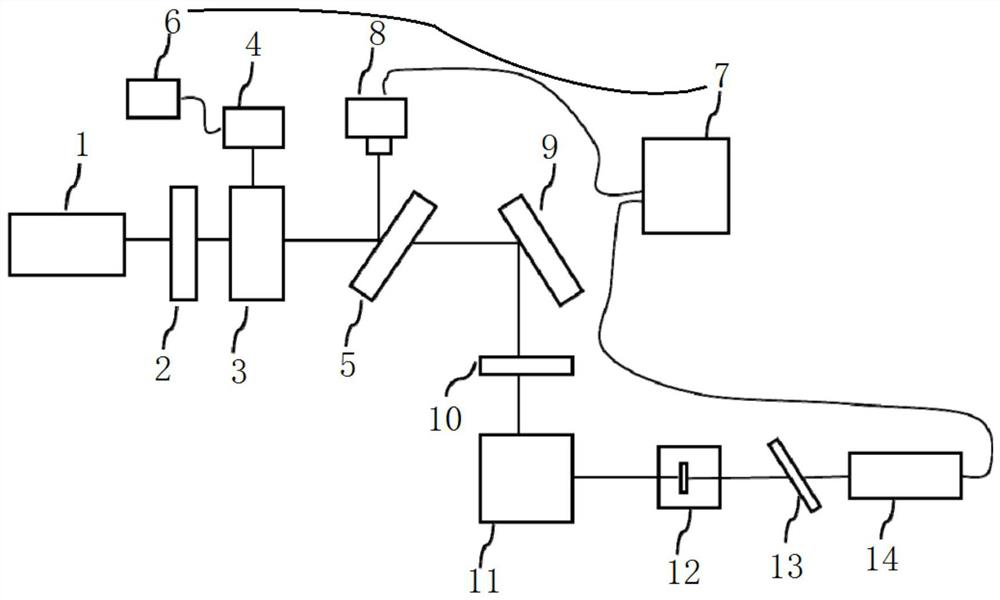

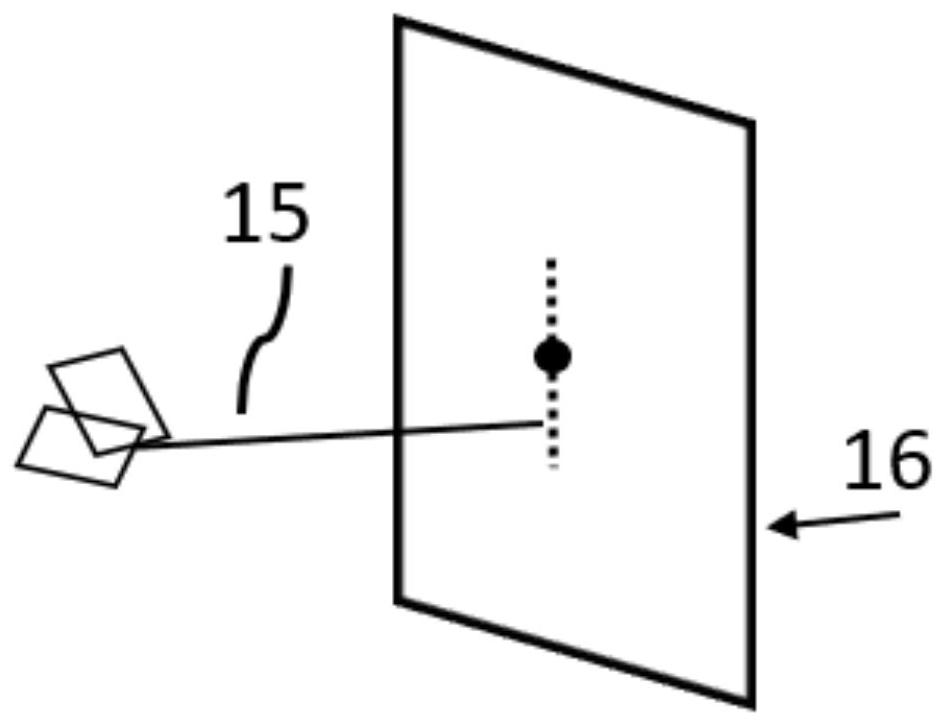

[0029] Such as figure 1 A laser spot welding micro-soldering spot quality detection device based on laser ultrasound includes: an ultrasonic signal excitation device, an ultrasonic signal detection device and a signal processing unit. The ultrasonic signal excitation device includes a nanosecond pulse laser 1, the wavelength of the nanosecond pulse laser 1 is 532nm or 1064nm, and the pulse width is 6-12ns, preferably 8ns. Nanosecond pulsed laser 11 emits a beam of pulsed laser light 15, passes through half-wave plate 2 and polarizing beam splitter 3, splits out a certain proportion of laser light 15 to energy detector 4, and reads out through energy detector head 6 The beam energy of the pulsed laser 15 . A part of the laser light 15 split by the beam splitter 5 arrives at the photodetector 8 as a trigger signal, and another part of the laser light 15 split by the beam splitter 5 passes through the light reflector 9 and the diaphragm 10 and reaches the high-speed scanning gal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com