Production process and device of spiced beef jerky

A technology for spiced beef and a production device, which is applied to the forming of food, the function of food ingredients, and the preservation of meat/fish with chemicals, etc., can solve the problems of insufficient blood and water treatment, beef treatment, short shelf life, etc., and achieves fresh and tender meat. Good taste and smooth taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

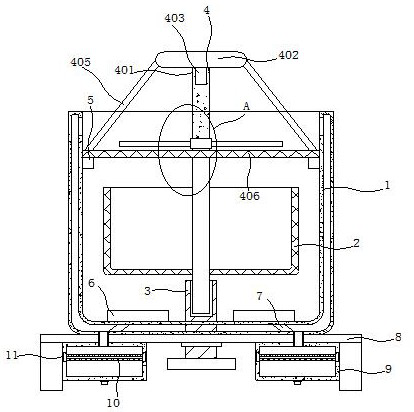

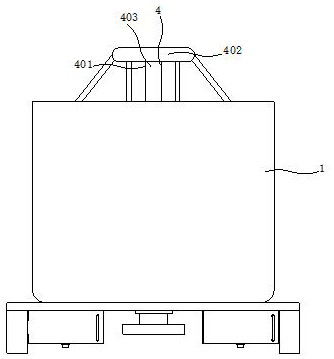

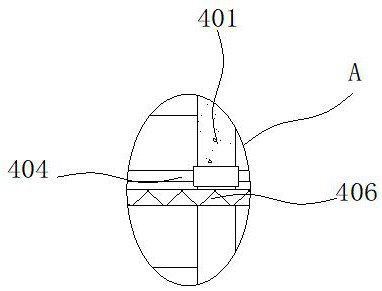

[0024] see Figure 1-3, the present invention provides a technical solution: Embodiment 1: a production process of spiced beef jerky, comprising the following steps: S1, raw material trimming: prepare the following raw materials, 150 parts of beef, 10 parts of onion slices, 5 parts of ginger slices, barbecue 3 parts of marinade, 6 parts of edible alkali, 10 parts of raw flour, 8 parts of peanut oil, 10 parts of egg white, 5 parts of rice wine, 4 parts of salt, 3 parts of pepper, 4 parts of soy sauce, 2 parts of green onion, 5 parts of sodium lactate and red yeast rice 6 parts of pigment, 3 parts of monosodium glutamate, 4 parts of chili powder, 4 parts of five-spice powder, 4 parts of white sugar and 6 parts of vegetable oil; choose beef hind legs that meet the national food hygiene standards, and use a sterilized knife to remove the fat, Remove sarcolemma and lymph, cut the raw meat into chunks along the texture of the beef muscle fiber, and put it in a container for later us...

Embodiment 2

[0025] Embodiment 2: A production process of spiced beef jerky, comprising the following steps: S1, raw material trimming: prepare the following raw materials, 180 parts of beef, 12 parts of onion slices, 6 parts of ginger slices, 4 parts of barbecue marinade, 7 parts of edible alkali , 15 parts of raw flour, 9 parts of peanut oil, 12 parts of egg white, 6 parts of rice wine, 5 parts of salt, 4 parts of chili, 5 parts of soy sauce, 3 parts of green onion, 6 parts of sodium lactate and 7 parts of red pigment, 4 parts of monosodium glutamate, 4 parts of chili 5 parts of flour, 5 parts of five-spice powder, 5 parts of sugar and 7 parts of vegetable oil; choose beef hind legs that meet the national food hygiene standards, use a sterilized knife to remove the fat, sarcolemma and lymph from the raw meat, and extend the beef muscle Fiber texture Cut the raw meat into chunks and put it in a container for later use; S2, soaking: put the beef in the container in S1 in the cleaning pool, ...

Embodiment 3

[0026] Embodiment 3: A production process of spiced beef jerky, comprising the following steps: S1, raw material trimming: prepare the following raw materials, 200 parts of beef, 13 parts of onion slices, 7 parts of ginger slices, 5 parts of barbecue marinade, and 8 parts of edible alkali , 20 parts of raw flour, 10 parts of peanut oil, 13 parts of egg white, 7 parts of rice wine, 6 parts of salt, 5 parts of chili, 6 parts of soy sauce, 4 parts of green onion, 7 parts of sodium lactate and 8 parts of red yeast rice, 5 parts of monosodium glutamate, 5 parts of chili 6 parts of flour, 6 parts of five-spice powder, 6 parts of sugar and 8 parts of vegetable oil; choose beef hind legs that meet the national food hygiene standards, use a sterilized knife to remove the fat, sarcolemma and lymph from the raw meat, and extend the beef muscle Fiber texture Cut the raw meat into pieces and put it in a container for later use; S2, soaking: put the beef in the container in S1 in the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com