Roasted sausage crisp chips and processing method thereof

A processing method and a technology of crisp flakes, which are used in processed meat, food drying, sausage casings, etc., to achieve the effects of convenient storage and consumption, improved lubricity and toughness, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

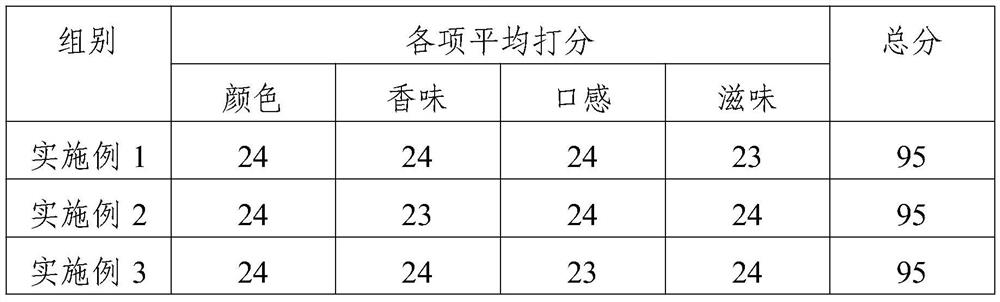

Embodiment 1

[0030] A crispy slice of grilled sausage, the crispy slice of grilled sausage comprises an outer casing and an inner filling, and the inner filling is made of the following raw materials in parts by weight: 60 parts of chicken, 20 parts of pork belly, 15 parts of pig skin, tea 1 part of oil, 12 parts of yuba, 4 parts of shiitake mushrooms, 1 part of rice noodles, 2 parts of starch, 1 part of sugar, 0.5 parts of glucose, 0.5 parts of table salt, 2 parts of soybean protein, 0.1 part of chicken essence, 0.1 part of thirteen spices, 0.5 parts of pepper share.

[0031] Preferably, the outer casing is treated with salt and casing treatment solution, wherein the casing treatment solution is made of the following raw materials in parts by weight: 0.8 parts of sucrose ester, 4 parts of edible glycerin, 3 parts of rice wine, 3 parts of lemon, 1 part of corn silk 1 part, 4 parts water, 2 parts olive oil.

[0032] The processing method of the crispy slices of grilled sausage comprises th...

Embodiment 2

[0042] A crispy slice of grilled sausage. The crispy slice of grilled sausage consists of an outer casing and an inner filling. The inner filling is made of the following raw materials in parts by weight: 80 parts of chicken, 30 parts of pork belly, 20 parts of pig skin, tea 5 parts of oil, 14 parts of yuba, 6 parts of shiitake mushrooms, 3 parts of rice noodles, 6 parts of starch, 2 parts of sugar, 1 part of glucose, 0.8 parts of salt, 8 parts of soybean protein, 0.3 parts of chicken essence, 0.3 parts of thirteen spices, 1 part of pepper share.

[0043] Preferably, the outer casing is treated with salt and casing treatment solution, wherein the casing treatment solution is made of the following raw materials in parts by weight: 1.2 parts of sucrose ester, 6 parts of edible glycerin, 4 parts of rice wine, 6 parts of lemon, 2 parts of corn silk 5 parts of water, 4 parts of olive oil.

[0044] The processing method of the crispy slices of grilled sausage comprises the followin...

Embodiment 3

[0054] A crispy slice of grilled sausage. The crispy slice of grilled sausage consists of an outer casing and an inner filling. The inner filling is made of the following raw materials in parts by weight: 70 parts of chicken, 25 parts of pork belly, 18 parts of pig skin, tea 3 parts of oil, 13 parts of yuba, 5 parts of shiitake mushrooms, 2 parts of rice noodles, 4 parts of starch, 1.5 parts of sugar, 0.8 parts of glucose, 0.7 parts of salt, 5 parts of soybean protein, 0.2 parts of chicken essence, 0.2 parts of thirteen spices, 0.8 parts of pepper share.

[0055] Preferably, the outer casing is treated with salt and casing treatment solution, wherein the casing treatment solution is made of the following raw materials in parts by weight: 1 part of sucrose ester, 5 parts of edible glycerin, 3.5 parts of rice wine, 5 parts of lemon, 1.5 parts of corn silk 4.5 parts of water, 3 parts of olive oil.

[0056] The processing method of the crispy slices of grilled sausage comprises t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com