Preparation process of ganoderma lucidum spore oil soft capsule

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spores is applied in the directions of capsule delivery, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. It can solve the problem that the disintegration time of soft capsules affects product stability and quality, extraction failure, The separation kettle is easy to block and other problems, so as to achieve the effect of improving the wall breaking rate, improving the extraction rate and high biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

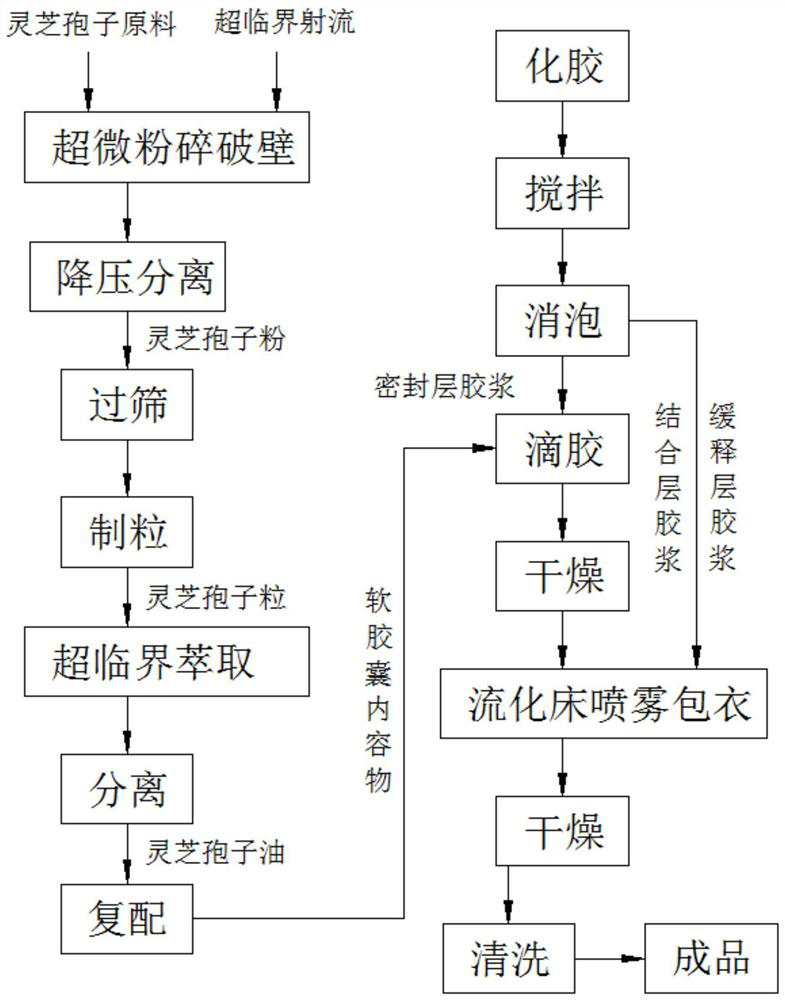

Image

Examples

Embodiment 1

[0022] A kind of preparation technology of Ganoderma lucidum spore oil soft capsule, its processing step is as follows:

[0023] S1: take the ganoderma lucidum spore raw material, sieve and granulate the ganoderma lucidum spore granules after ultrafine pulverization and wall breaking;

[0024] Supercritical CO is used in ultrafine pulverization and wall breaking treatment 2 Through the nozzle, the ganoderma spore raw material is brought to hit the hard target at a pressure of 35MPa and a temperature of -12°C for jet crushing, and the pressure is reduced to 8Mpa to separate and obtain the ganoderma spore powder. The sieving fineness is 300 mesh. The granulation mechanism of the ganoderma spore powder is as follows: 80 mesh ganoderma spores and vacuum-dried;

[0025] S2: Take Ganoderma lucidum spores and undergo supercritical extraction and separation to obtain Ganoderma lucidum spore oil, Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, soybean lecithin, active ...

Embodiment 2

[0033] A kind of preparation technology of Ganoderma lucidum spore oil soft capsule, its processing step is as follows:

[0034] S1: take the ganoderma lucidum spore raw material, sieve and granulate the ganoderma lucidum spore granules after ultrafine pulverization and wall breaking;

[0035] Supercritical CO is used in ultrafine pulverization and wall breaking treatment 2 Through the nozzle, the ganoderma spore raw material is brought to hit the hard target at a pressure of 40MPa and a temperature of 5°C for jet crushing, and the pressure is reduced to 9Mpa to separate and obtain the ganoderma spore powder. The sieving fineness is 300 mesh, and the ganoderma spore powder is granulated to 60 Objective ganoderma lucidum spores and vacuum drying;

[0036] S2: Take Ganoderma lucidum spores and undergo supercritical extraction and separation to obtain Ganoderma lucidum spore oil. The mass ratio of Ganoderma lucidum spore oil to Ganoderma lucidum spore powder, soybean lecithin, a...

Embodiment 3

[0045] A kind of preparation technology of Ganoderma lucidum spore oil soft capsule, its processing step is as follows:

[0046] S1: take the ganoderma lucidum spore raw material, sieve and granulate the ganoderma lucidum spore granules after ultrafine pulverization and wall breaking;

[0047] Supercritical CO is used in ultrafine pulverization and wall breaking treatment 2 Through the nozzle, the ganoderma spore raw material is brought to hit the hard target at a pressure of 26MPa and a temperature of 10°C for jet crushing, and the pressure is reduced to 8Mpa to separate and obtain the ganoderma spore powder. The sieving fineness is 300 mesh, and the ganoderma spore powder is granulated to 100 Objective ganoderma lucidum spores and vacuum drying;

[0048] S2: Take Ganoderma lucidum spores and undergo supercritical extraction and separation to obtain Ganoderma lucidum spore oil. The mass ratio of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, soybean lecithin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com