Green and environment-friendly process for synthesizing bromoacetate by solvent-free method

A bromoacetate, green and environmentally friendly technology, applied in the field of chemical manufacturing, can solve the problems of difficult catalyst recovery, low production efficiency, poor safety, etc., and achieve the effects of avoiding occupational health hazards, improving production efficiency, and avoiding safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of green environmental protection technology of solvent-free synthetic bromoacetate, comprises the steps:

[0020] 1) Mixing: Put 695kg of bromoacetic acid, 220kg of 1,4-butene diol and 2kg of sodium bisulfate into the reactor, start stirring, turn on the vacuum pump system to adjust the pressure to -0.085Mpa, and slowly heat to 50°C; 2) Reaction: After the reaction starts, slowly increase the reaction temperature to 95°C within 4.5 hours, and keep it for 1.4 hours, then take a sample for analysis; 3) Finished product: After the reaction is completed, cool down to room temperature, seal and filter the reaction solution, and transfer it to a dehydration kettle for use Maintain a high vacuum of -0.098Mpa at 75°C for 1.3h to obtain 820kg of 1,4-bis(bromoacetoxy)-2-butene as a brown oily liquid with a yield of 90.46%.

Embodiment 2

[0022] A kind of green environmental protection technology of solvent-free synthetic bromoacetate, comprises the steps:

[0023] 1) Mixing: Put 695kg of bromoacetic acid, 220kg of 1,4-butene diol and 2kg of sodium bisulfate into the reactor, start stirring, turn on the vacuum pump system to adjust the pressure to -0.085Mpa, and slowly heat to 50°C; 2) Reaction: After the reaction starts, slowly raise the reaction temperature to 95°C within 5.5 hours, and keep it for 1.8 hours, then take a sample for analysis; 3) Finished product: After the reaction is completed, cool down to room temperature, seal and filter the reaction solution, and transfer it to a dehydration kettle for use -0.098Mpa high vacuum was maintained at 78°C for 1.6h, and 820kg of 1,4-bis(bromoacetoxy)-2-butene was obtained as a brown oily liquid with a yield of 90.28%.

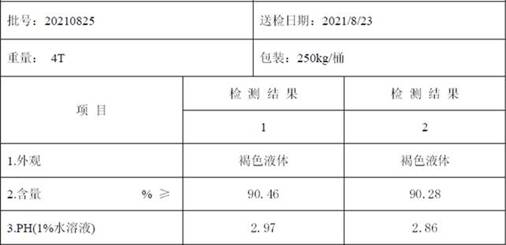

[0024] The parameter indexes of Embodiment 1 and Embodiment 2 are shown in the table below.

[0025]

[0026] A kind of green environmental...

Embodiment 3

[0029] A kind of green environmental protection technology of solvent-free synthetic bromoacetate, comprises the steps:

[0030] 1) Mixing: Put 695kg of bromoacetic acid, 155kg of ethylene glycol and 2kg of sodium bisulfate into the reactor, start stirring, turn on the vacuum pump system to adjust the pressure to -0.085Mpa, and slowly heat to 50°C; 2) Reaction: After the reaction starts , slowly raise the reaction temperature to 95°C within 5 hours, and keep it for 1.5 hours, and take samples for analysis; 3) Finished product: After the reaction is completed, cool down to room temperature, seal and filter the reaction solution, transfer it to the dehydration kettle and use -0.098Mpa high vacuum in the Keep at 75°C for 1.5h to obtain 750kg of 1,4-bis(bromoacetoxy)-2-butene as a brown oily liquid with a yield of 93%.

[0031] The parameter indexes of the second embodiment are shown in the table below.

[0032]

[0033] The invention is a green and environment-friendly proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com