Seawater-resistant oil-resistant elastic epoxy ballast tank coating and preparation method

A ballast tank, seawater-resistant technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve toughness, fatigue resistance, heat resistance, poor impact resistance, high epoxy resin crosslinking density, difficult Meet performance requirements and other issues, and achieve the effects of excellent flexibility, excellent physical and mechanical properties, good corrosion resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

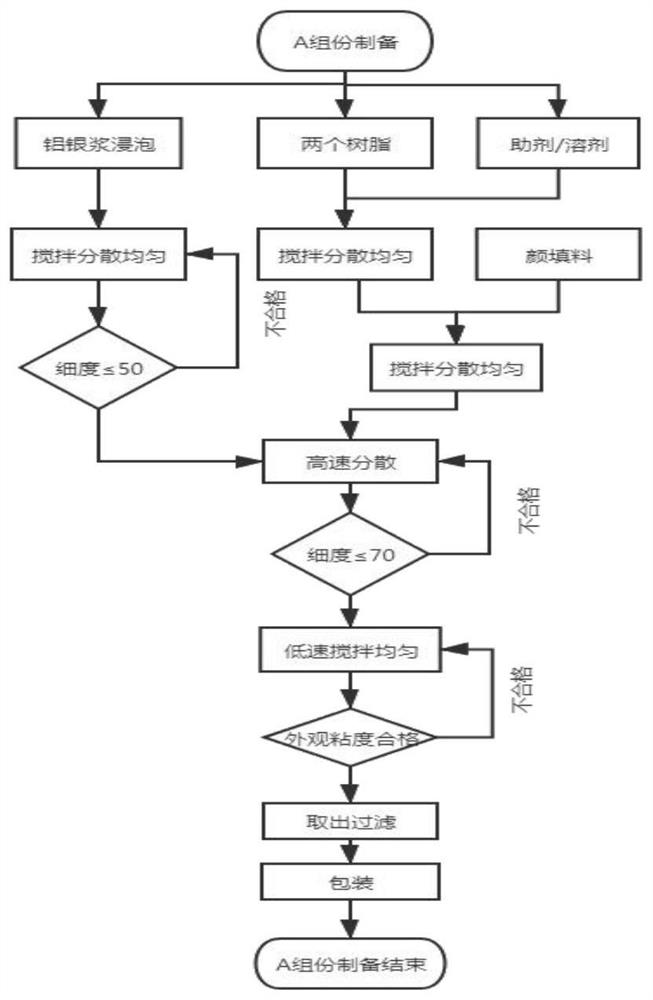

[0076] A component preparation includes the following steps:

[0077] S1. Preparation of aluminum-silver paste: Add aluminum paste, n-butanol, and benzyl alcohol that meet the formula requirements into the reaction kettle in sequence. It is uniform without sinking agglomerates and particles, that is, the self-made aluminum-silver paste is obtained, and the aluminum-silver paste needs to be prepared and used immediately;

[0078] S2. Add the dimer acid modified epoxy resin, epoxy resin, and xylene that meet the formula requirements into the reactor according to the proportion of the formula and stir at a low speed. The speed is controlled at 300r / min. After completion, increase the rotation speed to 1200r / min and disperse at high speed for 20 minutes;

[0079] S3. Add feldspar powder, talc powder, defoamer, anti-sedimentation agent, and benzyl alcohol at one time, continue to stir and heat up to 50°C and keep it warm for 40 minutes, then add self-made silver-aluminum paste and...

Embodiment 2

[0088] A component preparation includes the following steps:

[0089] S1. Preparation of aluminum-silver paste: Add aluminum paste, n-butanol, and benzyl alcohol that meet the formula requirements into the reaction kettle in sequence. It is uniform without sinking agglomerates and particles, that is, the self-made aluminum-silver paste is obtained, and the aluminum-silver paste needs to be prepared and used immediately;

[0090] S2. Add the dimer acid modified epoxy resin, epoxy resin, and xylene that meet the formula requirements into the reactor according to the proportion of the formula and stir at a low speed. The speed is controlled at 400r / min. After completion, increase the speed to 1300r / min and disperse at high speed for 17 minutes;

[0091] S3. Add feldspar powder, talc powder, defoamer, anti-sedimentation agent, benzyl alcohol at one time, continue to stir and heat up to 60°C for 30 minutes, then add self-made silver-aluminum paste and continue to disperse for 7 mi...

Embodiment 3

[0101] A component preparation includes the following steps:

[0102] S1. Preparation of aluminum-silver paste: Add aluminum paste, n-butanol, and benzyl alcohol that meet the formula requirements into the reaction kettle in sequence. It is uniform without sinking agglomerates and particles, that is, the self-made aluminum-silver paste is obtained, and the aluminum-silver paste needs to be prepared and used immediately;

[0103] S2. Add the dimer acid modified epoxy resin, epoxy resin, and xylene that meet the formula requirements into the reactor according to the proportion of the formula and stir at a low speed. The speed is controlled at 500r / min. After completion, increase the speed to 1400r / min and disperse at high speed for 15 minutes;

[0104] S3. Add feldspar powder, talc powder, defoamer, anti-sedimentation agent, and benzyl alcohol at one time, continue to stir and heat up to 70°C for 20 minutes, then add self-made silver-aluminum paste and continue to disperse for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com