Inorganic fiber powder for radiation cooling and preparation method thereof

An inorganic fiber and radiation cooling technology, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of easy aging and degradation, and achieve the effect of low cost, simple equipment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

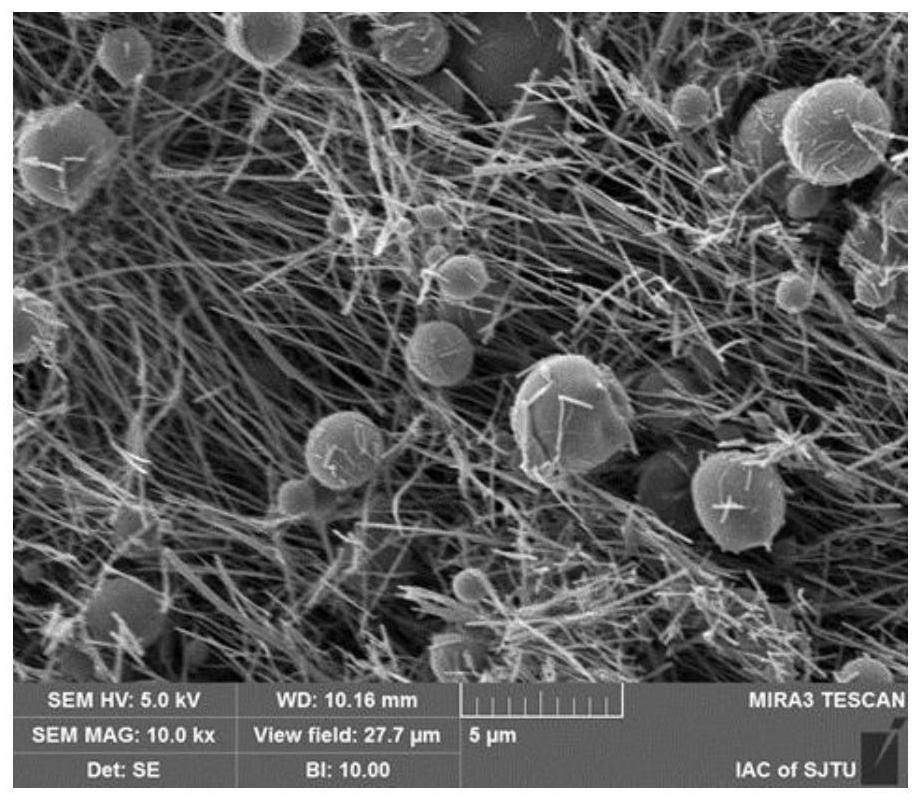

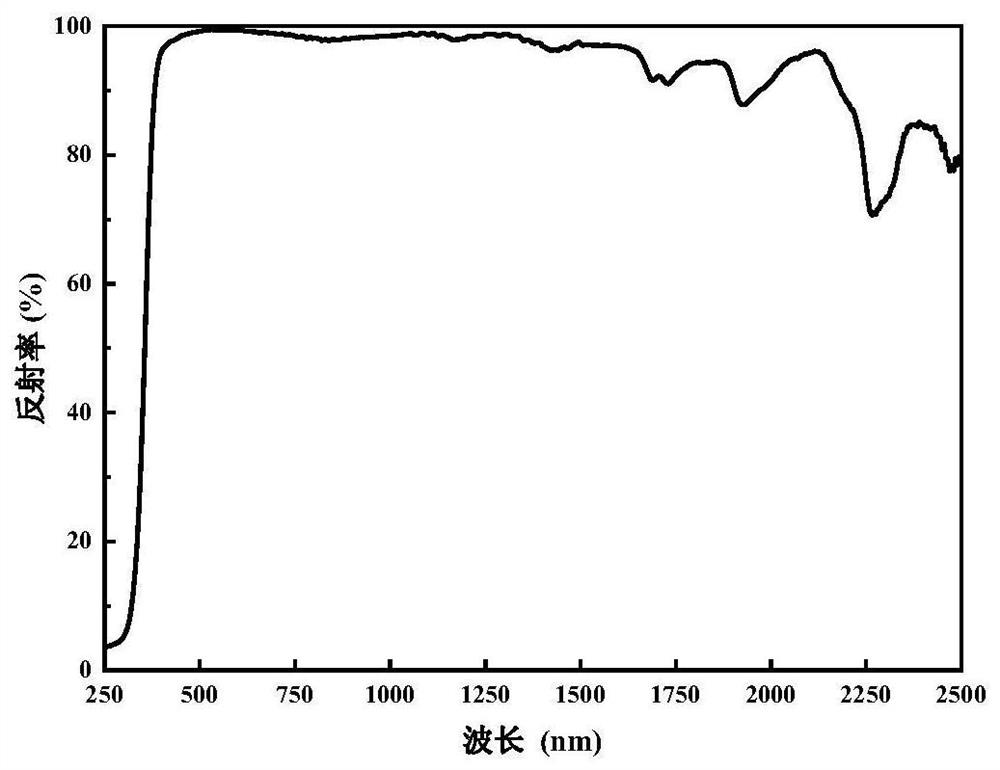

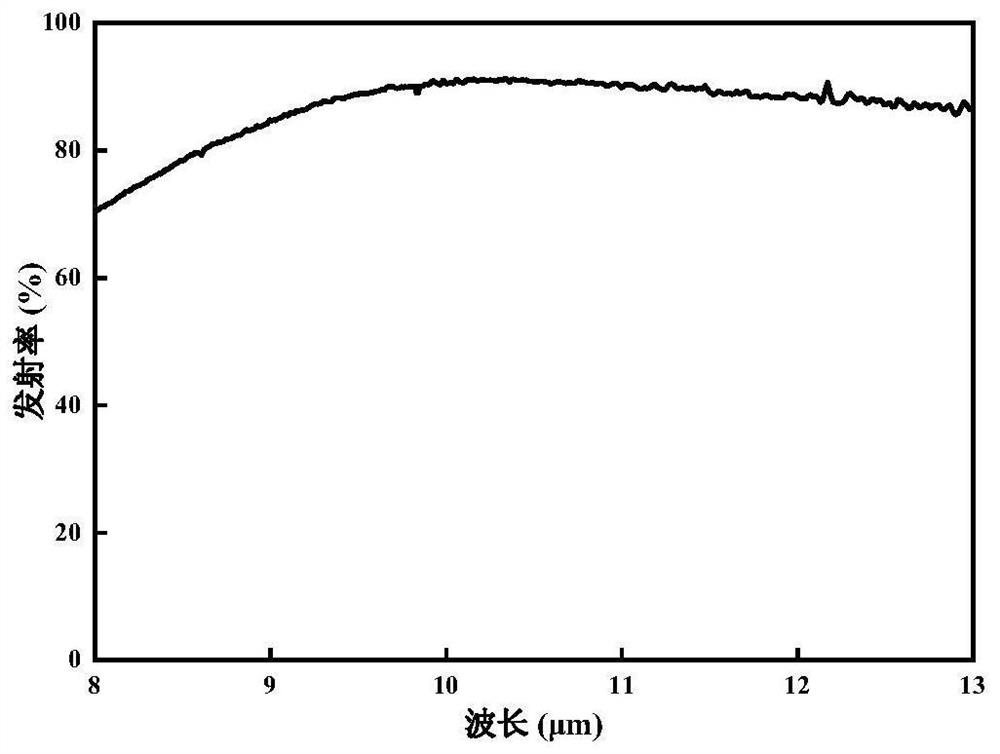

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned inorganic fiber powder for radiative cooling comprises the following steps:

[0037] S1: Add the high polymer to the acetic acid ethanol solution, stir it magnetically for 5 hours, the mass fraction of the high polymer is 2wt%; the acetic acid ethanol solution is a mixed solution of acetic acid and ethanol with a mass ratio of 2:3;

[0038] The high polymer is polyvinylpyrrolidone (PVP), polyethylene oxide (PEO), polyvinyl alcohol (PVA) or polyvinyl butyral (PVB).

[0039] S2: Add a preset ratio of alkoxide to the polymer gel, and then dropwise add tetraethyl orthosilicate hydrolyzate or other alkoxide or dispersion corresponding to ceramic microspheres to obtain an electrospinning precursor , and vacuum degassing, the mass proportion of alkoxide in the electrospinning precursor solution is 10%-30%, and the volume ratio of tetraethylorthosilicate hydrolyzate to polymer gel is 1:5;

[0040] The alkoxide is one or more of the...

Embodiment 1

[0045] First prepare tetraethyl orthosilicate hydrolyzate, mix tetraethyl orthosilicate, ethanol, 0.1mol / L hydrochloric acid with the volume ratio of 5:5:1 and magnetically stir to obtain tetraethyl orthosilicate hydrolyzate use.

[0046] Then mix acetic acid and ethanol according to the mass ratio of 2:3 and stir evenly, then add 2wt% polyvinylpyrrolidone (PVP) to the acetate-ethanol mixed solution, and stir thoroughly for 5 hours to obtain a high polymer sol. In the high polymer sol, add tetratitanium isopropoxide and account for 10% of the total solution mass, and dropwise add tetraethyl orthosilicate hydrolyzate (tetraethyl orthosilicate hydrolyzate and high polymer sol volume ratio are 1:5), and magnetically stirred in a 60°C water bath for 1 h to obtain the electrospinning precursor solution, which was then vacuumed and degassed.

[0047] The electrospinning positive voltage was 20kV, the negative voltage was -2kV, the extrusion speed of the spinning solution was 2mL / h,...

Embodiment 2

[0049] First prepare tetraethyl orthosilicate hydrolyzate, mix tetraethyl orthosilicate, ethanol, 0.1mol / L hydrochloric acid with the volume ratio of 5:5:1 and magnetically stir to obtain tetraethyl orthosilicate hydrolyzate use.

[0050] Then acetic acid and ethanol were mixed and stirred evenly at a mass ratio of 2:3, and then 10 wt% polyvinylpyrrolidone (PVP) was added to the acetate-ethanol mixed solution, and stirred thoroughly for 5 hours to obtain a high polymer sol. In the sol, add tetratitanium isopropoxide, which accounts for 20% of the total solution mass, and add tetraethyl orthosilicate hydrolyzate drop by drop (the volume ratio of tetraethyl orthosilicate hydrolyzate and high polymer sol is 1:5 ), and magnetically stirred in a water bath at 60° C. for 1 h to obtain an electrospinning precursor solution, which was then vacuumed and degassed.

[0051] The positive voltage of electrospinning was 20kV, the negative voltage was -2kV, the extrusion speed of the spinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com