Double-layer conductor separable double-layer insulator wire and processing method thereof

A processing method and insulator technology, applied in the field of electric wires, can solve problems such as unsatisfactory environmental protection performance and energy-saving effect, reduction in strength and hardness of aluminum wires, and influence on the overall performance of wires, so as to improve convenience, improve conductivity, and appearance rounded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

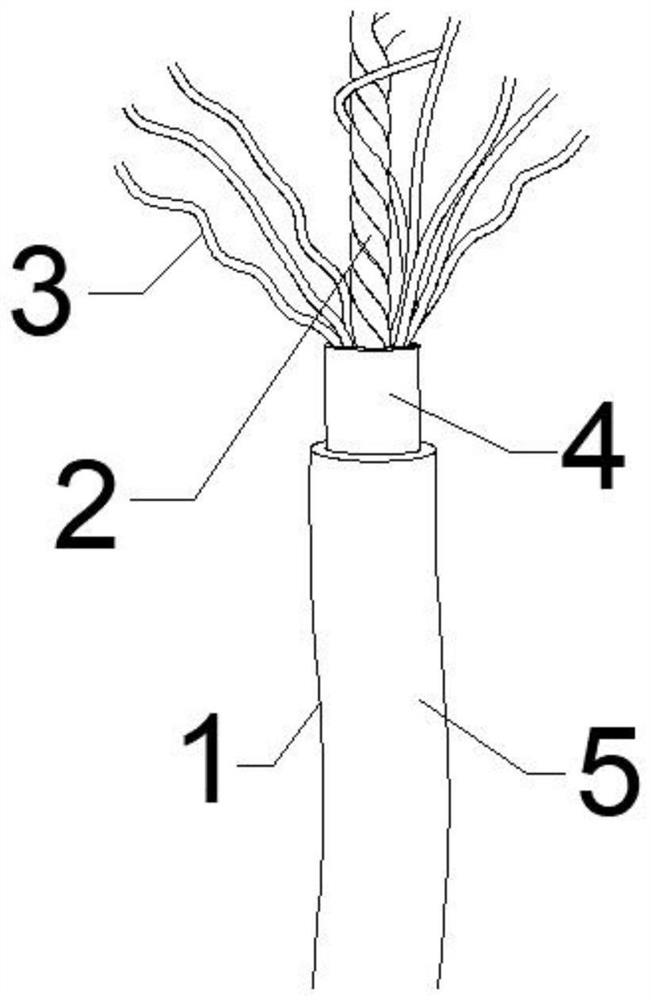

[0026] Such as figure 1 As shown, a double-layer conductor with separable double-layer insulator electric wire and its processing method include an electric wire 1, a main conductor 2, an outer conductor 3, an inner insulating sheath 4 and an outer insulating sheath 5, and said main conductor 2 is wrapped with an outer sheath layer wire 3, the outer layer wire 3 is covered with an inner insulating sheath 4, and the outer periphery of the inner insulating sheath 4 is sheathed with an outer insulating sheath 5.

[0027] Wherein, described specifically include following processing methods:

[0028] Step 1: Take aluminum, silicon, copper and boron for smelting, and then perform casting treatment. After casting and molding, roll the rod, and then finish the rod to obtain an alloy conductive rod. The diameter of the alloy conductive rod is ¢8mm, and the tensile strength is controlled At 85MPa, the resistivity of the conductor is less than 0.02Ω·mm2 / m at 20°C, and the elongation is ...

Embodiment 2

[0043] Such as figure 1 As shown, a double-layer conductor with separable double-layer insulator electric wire and its processing method include an electric wire 1, a main conductor 2, an outer conductor 3, an inner insulating sheath 4 and an outer insulating sheath 5, and said main conductor 2 is wrapped with an outer sheath layer wire 3, the outer layer wire 3 is covered with an inner insulating sheath 4, and the outer periphery of the inner insulating sheath 4 is sheathed with an outer insulating sheath 5.

[0044] Wherein, described specifically include following processing methods:

[0045] Step 1: Take aluminum, silicon, copper and boron for smelting, followed by casting treatment, after casting and molding, roll the rod, and then finish the rod to obtain the alloy conductive rod, and the diameter of the alloy conductive rod is ¢16.5mm, the tensile strength Controlled at 145MPa, the resistivity of the conductor is less than 0.02Ω·mm2 / m at 20°C, and the elongation is gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com