A converter primary dust removal system for reducing particulate matter emission and using method thereof

A dust removal system and particle technology, applied in the field of converter dust removal, can solve the problems of increasing investment, operation management and operation maintenance costs, reducing the space occupied by the dehydrator, and failing to meet environmental protection requirements, etc., to achieve good fluid mechanics performance, Optimize group layout and reduce system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

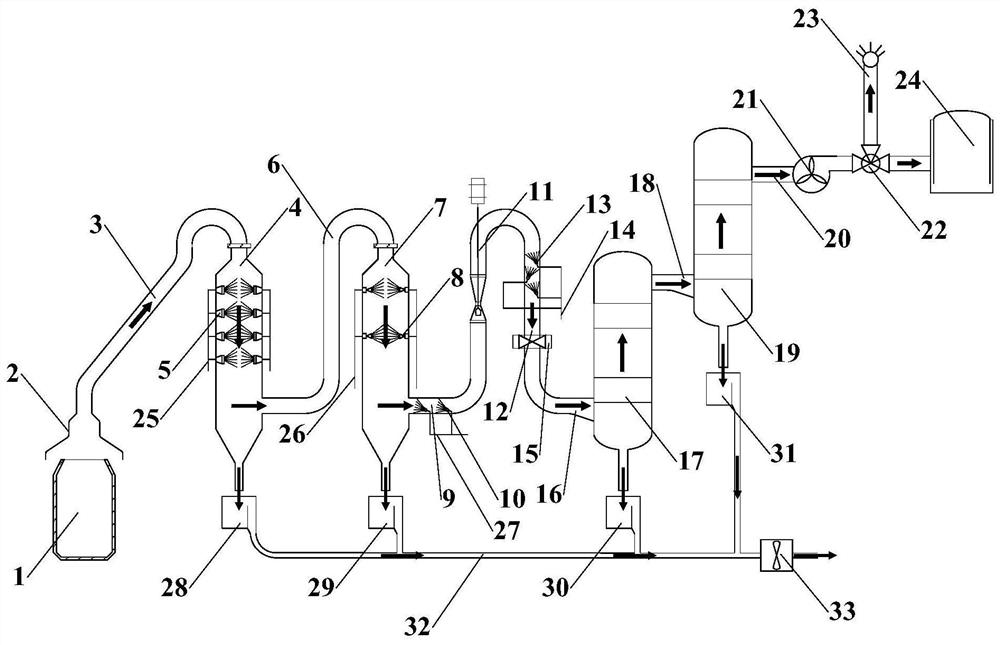

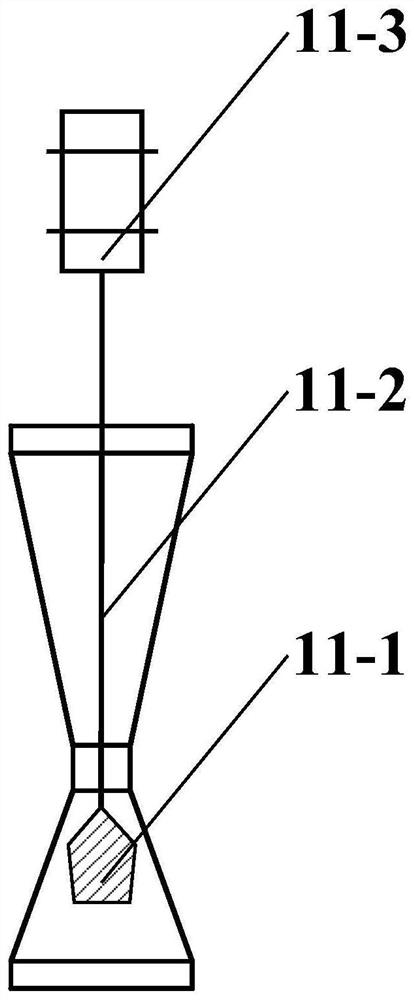

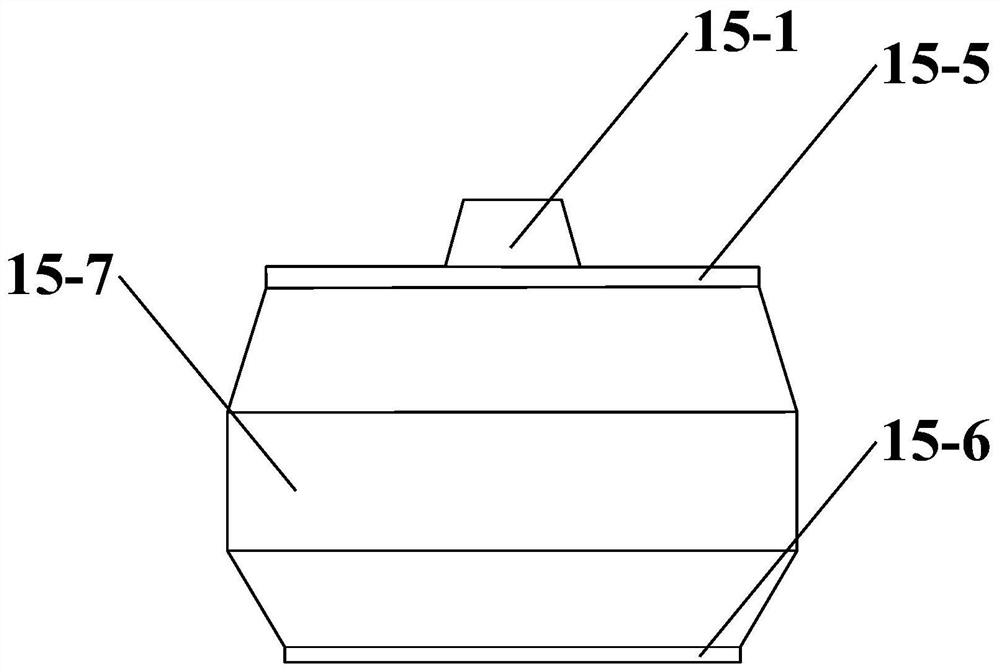

[0081] The structure of the primary dust removal system of the converter to reduce the emission of particulate matter is as follows: figure 1 As shown, it includes converter 1, primary spray washing tower 4, secondary spray washing tower 7, annular slit venturi 11, flue gas water mist separator 15, first cyclone dehydrator 17 and second cyclone dehydrator 19;

[0082] The flue gas collection hood 2 is matched with the converter 1, and the flue gas collection hood 2 is communicated with the top of the primary spray washing tower 4 through the vaporization cooling flue 3, and the lower part of the primary spray washing tower 4 and the top of the secondary spray washing tower 7 are adjusted by the system. The pressure pipe 6 is communicated, and the lower part of the secondary spray washing tower 7 is communicated with the lower end of the annular slot venturi 11 through the first flue gas pipeline 9; , the annular slit venturi 11 and the dust removal pipe 12 are communicated th...

Embodiment 2

[0113] The structure of the converter primary dust removal system for reducing particulate matter emission is the same as that in Example 1, except that:

[0114] (1) The first-stage conical blade swirl plate is composed of 4 blades, the second-stage conical blade swirl plate is composed of 4 blades, and the third-stage conical blade swirl plate is composed of 6 blades;

[0115] (2) The blade bending inclination angle of the first-stage conical blade swirl plate is 7°; the blade bending inclination angle of the second-stage conical blade swirl plate is 7°; the blade bending inclination angle of the third-stage conical blade swirl plate is 9° ;

[0116] (3) There are 5 groups of dual-fluid aerosol spray guns inside the primary spray washing tower, and each group of dual-fluid aerosol spray guns has 4 nozzles; There are 5 nozzles in the pair of spray type spiral spray gun;

[0117] (4) There are 3 air-water atomizing spray guns in the first flue gas pipeline;

[0118] (5) The...

Embodiment 3

[0130] The structure of the converter primary dust removal system for reducing particulate matter emission is the same as that in Example 1, except that:

[0131] (1) The first-stage conical blade swirl plate is composed of 5 blades, the second-stage conical blade swirl plate is composed of 5 blades, and the third-stage conical blade swirl plate is composed of 7 blades;

[0132] (2) The blade bending inclination angle of the first-stage conical blade swirl plate is 9°; the blade bending inclination angle of the second-stage conical blade swirl plate is 9°; the blade bending inclination angle of the third-stage conical blade swirl plate is 10° ;

[0133] (3) There are 6 groups of dual-fluid aerosol spray guns inside the primary spray washing tower, and each group of dual-fluid aerosol spray guns has 6 nozzles; the interior of the secondary spray washing tower is equipped with 4 sets of pair-spraying spiral spray guns, each with 6 nozzles. There are 3 nozzles for the pair of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com