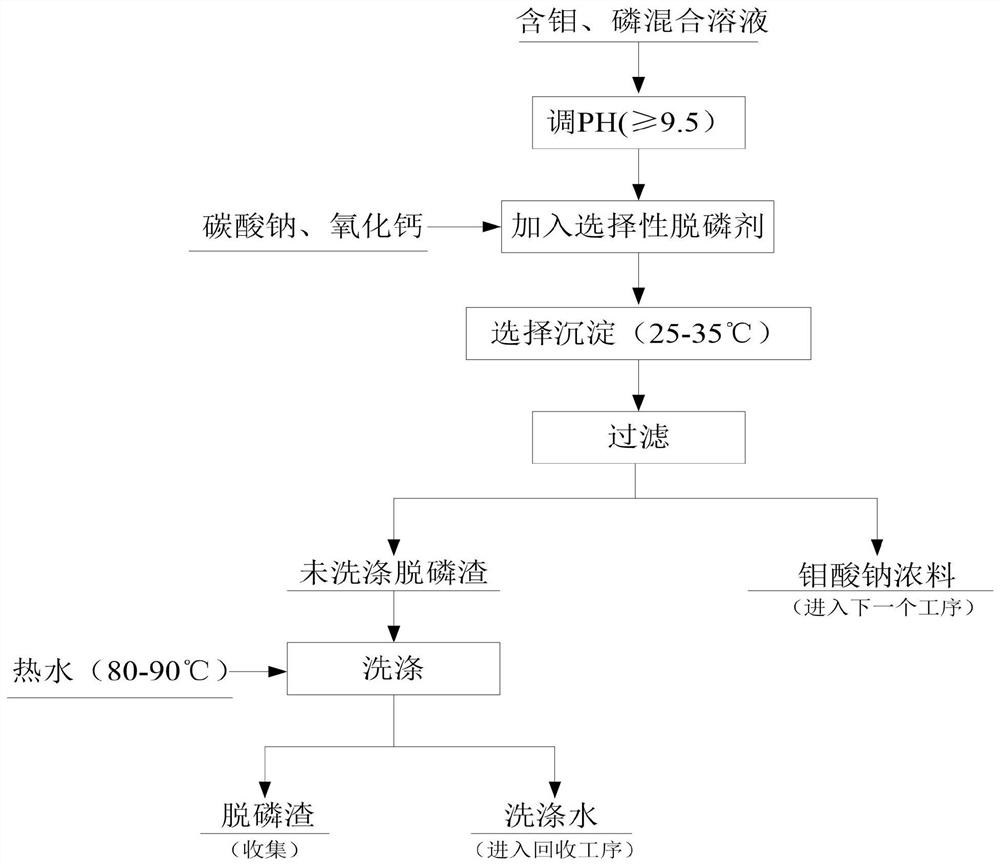

Method for selective dephosphorization in molybdenum and phosphorus mixed solution

A mixed solution, selective technology, applied in the direction of improving process efficiency, etc., can solve the problems of large equipment investment, cumbersome operation, easy co-precipitation of molybdenum, etc., achieve high selectivity, improve removal effect, and reduce co-precipitation loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The molybdenum and phosphorus mixed solution containing phosphorus in this example comes from a tungsten and molybdenum smelter N1923 in the separation of molybdenum and tungsten. Sampling and testing results of the molybdenum and phosphorus mixed solution: Mo 15g / L, P 0.67g / L.

[0016] (1) pH value adjustment: Measure 400mL molybdenum and phosphorus mixed solution, add a small amount of sodium hydroxide solution, control the pH of the molybdenum and phosphorus mixed solution to 10, stir for 10 minutes, and then enter the next step;

[0017] (2) Add selective dephosphorization agent: adjust the molybdenum, phosphorus mixed solution of pH value through step (1), calculate the quality of total phosphorus in 400ml solution to be 0.27g, total molybdenum quality is 6.0g, according to molybdenum, phosphorus For the total content of molybdenum and phosphorus in the mixed solution, add 6.0g of sodium carbonate (1.0 times the total amount of molybdenum), stir for 10min, then add ...

Embodiment 2

[0021] The phosphorus-containing molybdenum and phosphorus mixed solution in this example comes from a tungsten-molybdenum smelter N1923 during the separation of molybdenum and tungsten. Sampling and testing results of the molybdenum and phosphorus mixed solution: Mo 21.6g / L, P 1.6g / L.

[0022] (1) pH value adjustment: Measure 400mL molybdenum and phosphorus mixed solution, add a small amount of sodium hydroxide solution, control the pH of molybdenum and phosphorus mixed solution to 12, stir for 10min, and then enter the next step;

[0023] (2) Add selective dephosphorization agent: adjust the molybdenum, phosphorus mixed solution of pH value through step (1), calculate the quality of total phosphorus in 400ml solution to be 0.64g, total molybdenum quality is 8.64g, according to molybdenum, phosphorus For the total content of molybdenum and phosphorus in the mixed solution, add 17.28g of sodium carbonate (2.0 times the total amount of molybdenum), stir for 10min, then add calci...

Embodiment 3

[0027] The phosphorus-containing molybdenum and phosphorus mixed solution in this example comes from a tungsten-molybdenum smelter N1923 where molybdenum and tungsten are separated. Sampling and testing results of the molybdenum and phosphorus mixed solution: Mo 28.5g / L, P 0.54g / L.

[0028] (1) Adjust the pH value: Measure 400mL of molybdenum and phosphorus mixed solution, add a small amount of sodium hydroxide solution, control the pH of the molybdenum and phosphorus mixed solution to 11, stir for 10 minutes, and then enter the next step;

[0029] (2) Add selective dephosphorization agent: adjust the molybdenum, phosphorus mixed solution of pH value through step (1), calculate the quality of total phosphorus in 400ml solution to be 0.216g, total molybdenum quality is 11.4g, according to molybdenum, phosphorus For the total content of molybdenum and phosphorus in the mixed solution, add 17.1g of sodium carbonate (1.5 times the total amount of molybdenum), stir for 10min, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com