High-toughness corrosion-resistant FeCoNiCuAl high-entropy alloy wave-absorbing material as well as preparation method and application thereof

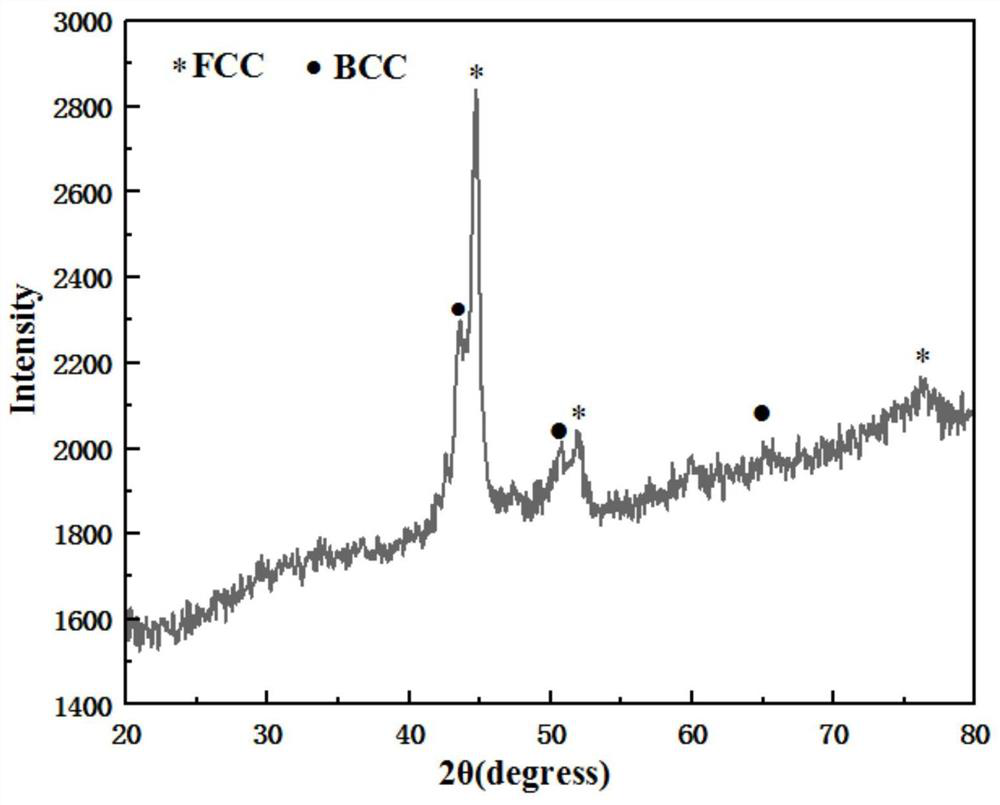

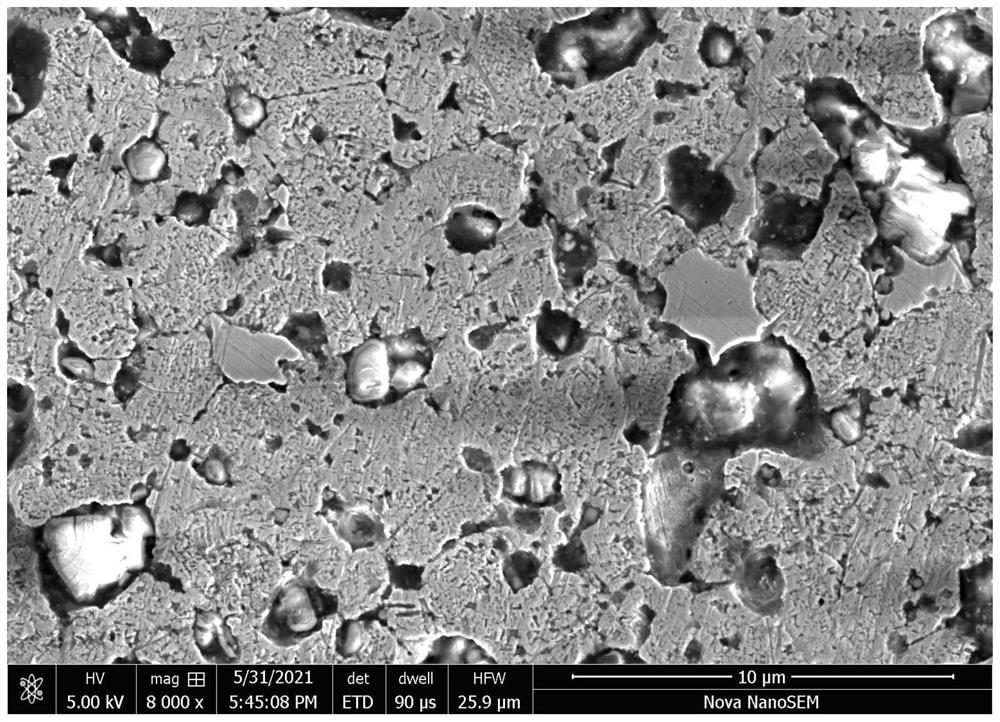

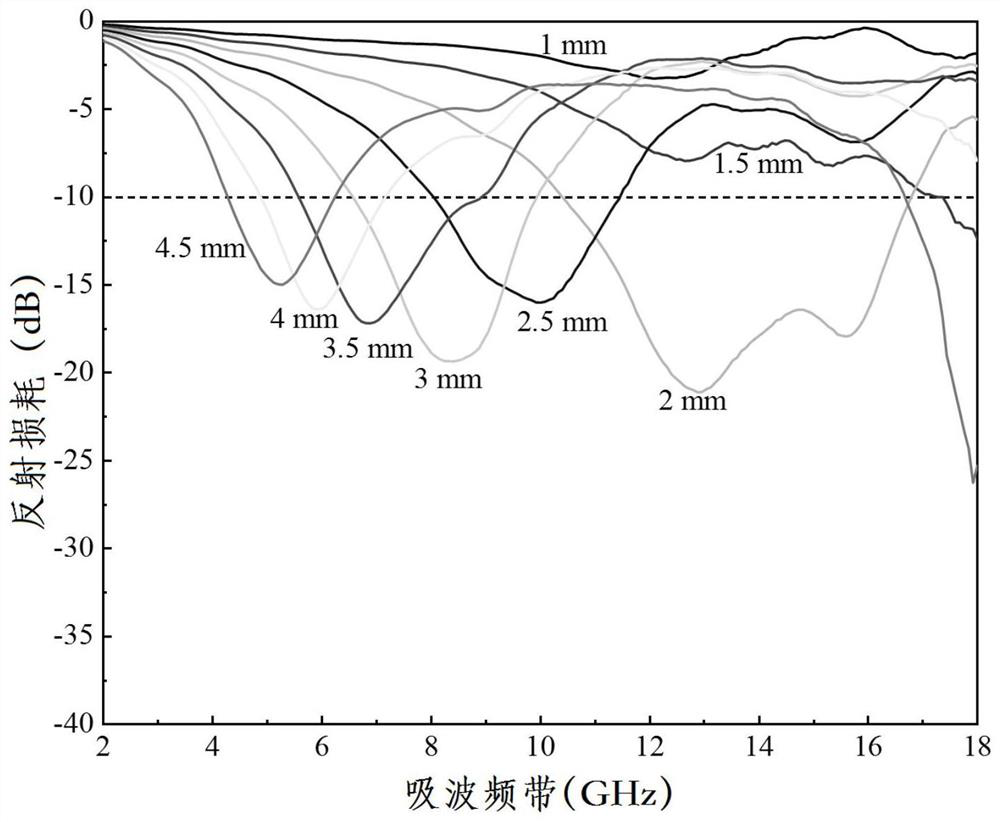

A high-entropy alloy and wave-absorbing material technology, which is applied in metallurgy and heat treatment of metal materials, and wave-absorbing materials, can solve problems such as poor wave-absorbing performance, non-corrosion resistance, and poor toughness, and achieve simple equipment, promotion of mutual dissolution, and reflection loss Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a high-strength, toughness, and corrosion-resistant FeCoNiCuAl high-entropy alloy wave-absorbing material, comprising the following steps:

[0041] Step 1: After mixing iron powder, cobalt powder, nickel powder, copper powder, and aluminum powder with a purity of 99.9% according to an equiatomic ratio, place them in a ball mill tank, and use a vacuum pump to completely evacuate the inside of the ball mill tank. The ultra-low temperature liquid nitrogen planetary ball mill is used to pass nitrogen gas to the outer wall of the stainless steel ball milling tank, while rotating at high speed to mechanically alloy the inside of the stainless steel ball milling tank, thereby producing high-entropy alloy powder. In the initial stage, the ball milling rate was set to 150r / min for 4h, and then the rate was set to 300r / min for 60h.

[0042] Step 2: The ball-milled powder was placed in a vacuum oven at 72°C to remove excess ethanol. After drying, cold press...

Embodiment 2

[0046] A method for preparing a high-strength, toughness, and corrosion-resistant FeCoNiCuAl high-entropy alloy wave-absorbing material, comprising the following steps:

[0047] Step 1: Put iron powder, cobalt powder, nickel powder, copper powder, aluminum powder and other powders with a purity of 99.9% in an equiatomic ratio, mix the powder and place it in a ball mill tank, and use a vacuum pump to completely pump the inside of the ball mill tank Vacuum, ultra-low temperature liquid nitrogen planetary ball mill is used to pass nitrogen gas to the outer wall of the stainless steel ball mill, while rotating at high speed to mechanically alloy the inside of the stainless steel ball mill, thereby producing high-entropy alloy powder. In the initial stage, the ball milling rate was set to 150r / min for 8h, and then the rate was set to 300r / min for 60h.

[0048] Step 2: The ball-milled powder was placed in a vacuum oven at 72°C to remove excess ethanol. After drying, cold press and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com