Textile structure material with stab-resistant performance

A textile structure and performance technology, applied in the textile field, can solve problems such as easy formation of stab-proof loopholes, excessive exposure of tissue points, and easy peeling off of scales, so as to reduce the exposure of tissue points, improve stab-proof performance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

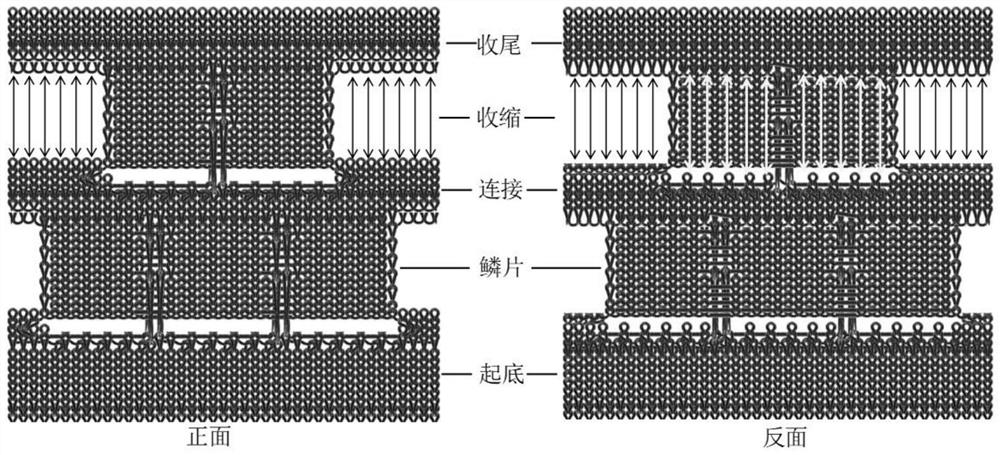

[0056] A weaving process for a stab-resistant textile structure material, comprising the steps of:

[0057] (1) Material selection:

[0058] Select ultra-high molecular weight polyethylene, nylon core-spun yarn and polyester yarn for weaving; the scale unit part is woven with 600D ultra-high molecular weight polyethylene (UHMWPE) and 100D7030 (outsourcing 70D nylon, containing 30D spandex) nylon core-spun yarn , 600D polyester yarn is used to weave the beginning and end of textile structural materials; in order to facilitate weaving, UHMWPE chooses twisted yarn with a twist number of 80 twists / m.

[0059] (2) Weaving:

[0060] Draw the plate-making process of the textile structure material (imitation scale structure fabric) in the computer plate-making system, and set the process parameters such as stitch, speed, and yarn feeder;

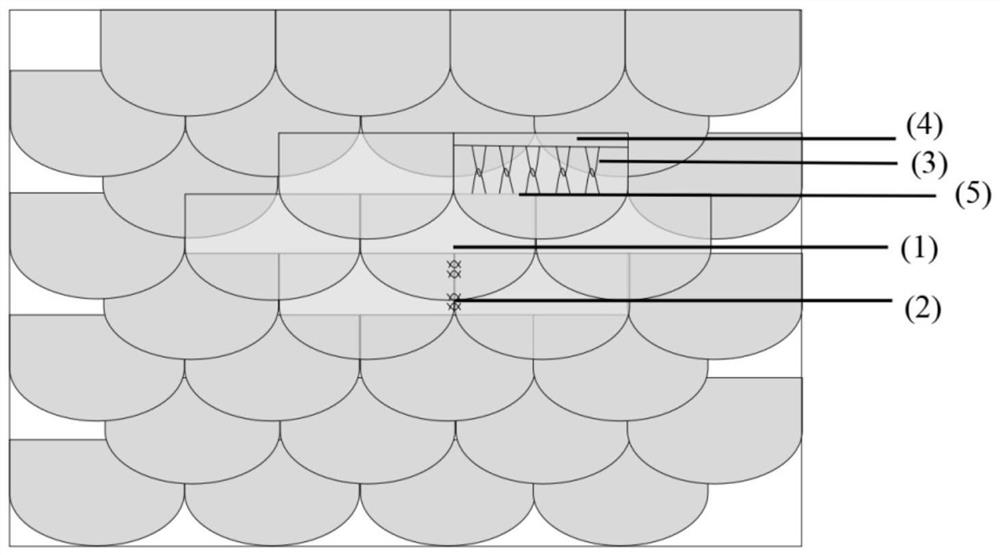

[0061] The textile structure material adopts domestic 14-needle double-needle bed computerized flat knitting machine (model KSC-132) to weave the...

Embodiment 2

[0081] Parameters and scale area coverage of embodiment 2 textile structure materials

[0082] According to the method of Example 1, a total of 9 specifications of textile structural materials were woven to investigate the relationship between scale area coverage and stab resistance.

[0083] The horizontal density of nine specifications of textile structural materials is about 7.7 coils / cm, the longitudinal density is 11.1 coils / cm, and the thread length is UHMWPE8.8cm / 50 needles. The changes in the number of rows and rows of scales will not affect the textile structural materials. of the overall size.

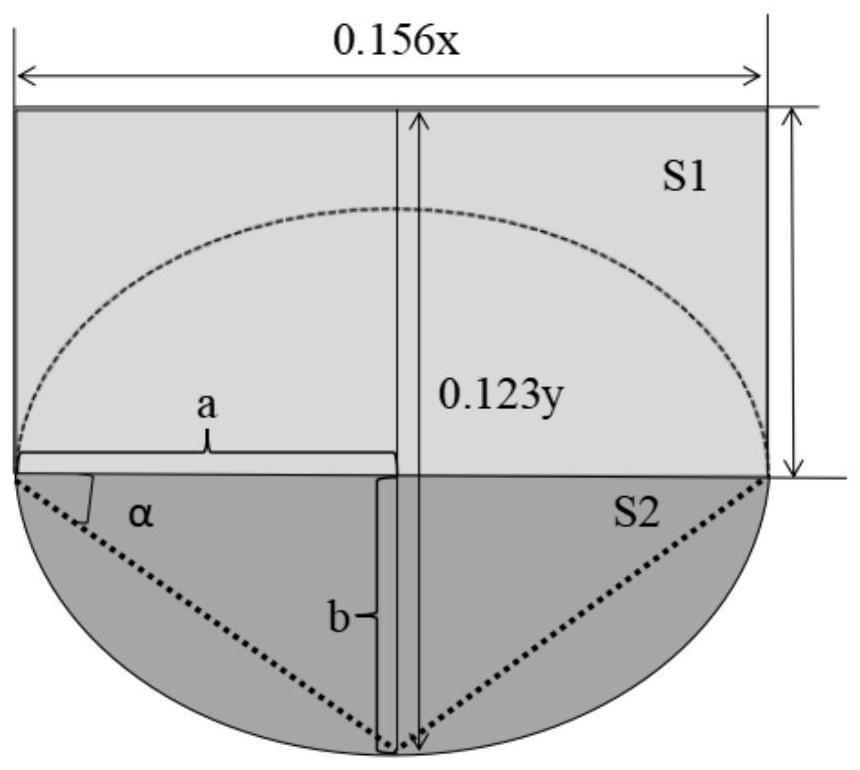

[0084] There are regular differences in the weight and area coverage of the nine textile structural materials. According to the scale structural unit model and the measurement of the deflection angle of the scale, the formula Sa for the overall area of the scale unit, the formula Sb for the area of the weak ring, and the area of the overlapping part of the scale can be ...

Embodiment 3

[0103] A weaving process for a stab-resistant textile structure material, comprising the steps of:

[0104] (1) material selection: with embodiment 1 step (1)

[0105] (2) Weaving:

[0106] On the basis of Example 1, start to weave the main part of the scale from the 14th way, this part is woven separately, only connected at the adjacent horizontal position, the number of ways is set at the 20th way and 21 way, 25 way and 26 way, the main body of the scale There is no connection in the whole process between the part and the connected part, and the coil is not disconnected until the 28-way braiding is completed. After the main part of the scale main part of the textile structural material is knitted, weave the connection part again, and the loop that has not been removed from the connection part of the previous cycle is threaded.

[0107] (3) Enhanced composite processing:

[0108] Using the template method (for details, see Figure 11 ) to process the main part of the scal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Coverage | aaaaa | aaaaa |

| Coverage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com