Plastic track playground construction method

A construction method, the technology of plastic track, applied in the direction of roads, roads, pavements, etc., can solve the problems of loose gravel, easy swelling and damage of the site, and achieve a firm base, improve the flatness and durability of the site, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A construction method for a plastic runway playground, comprising the following steps:

[0054] Step 1): According to the site design standards, select the site, plan the construction area, and clean up the construction area.

[0055] Step 2): backfilling stone chips in the construction area, layered static pressure, compaction and leveling, the compaction coefficient ≥ 90%, in this embodiment, the compaction coefficient is 95%; forming a stone chip leveling layer.

[0056] Step 3): Backfill the 280-320mm thick gravel cushion and compact it; and set the gravel blind ditch with a particle size of ≤30 grade, and set a blind pipe inside. In this embodiment, a 300 mm thick gravel cushion layer is backfilled with a particle size of 30 grades.

[0057]Step 4): laying a 185-210mm thick cement chip layer with a compaction coefficient ≥ 90% and a cement content of 4-6% to form a water-stable layer. In this embodiment, a 200mm thick cement chip layer is laid, the compaction coe...

Embodiment 2

[0065] A kind of plastic runway playground construction method, differs from embodiment 1 in that, after step 1) finishes clearing up construction area, also comprises following preprocessing step:

[0066] Step a): Pour 155-165mm thick reinforced concrete roof slabs in the construction area, and use the construction technology of mechanical puree grinding to smooth the roof slabs. In this embodiment, a 160mn thick reinforced concrete roof slab is poured.

[0067] Step b): laying C20 fine stone concrete slope-finding layer, the thickness of the thinnest part is 20, and the slope is not less than 0.5%. In this embodiment, the slope is 2%. When the slope thickness exceeds 50, the lower part shall be filled with lightweight ceramsite concrete with a strength grade of LC5.0 first, and then a 30-thick fine stone concrete surface layer shall be made. When encountering structural slope finding, step b) can be omitted directly.

[0068] Step c): Laying 20 thick cement mortar, compac...

Embodiment 3

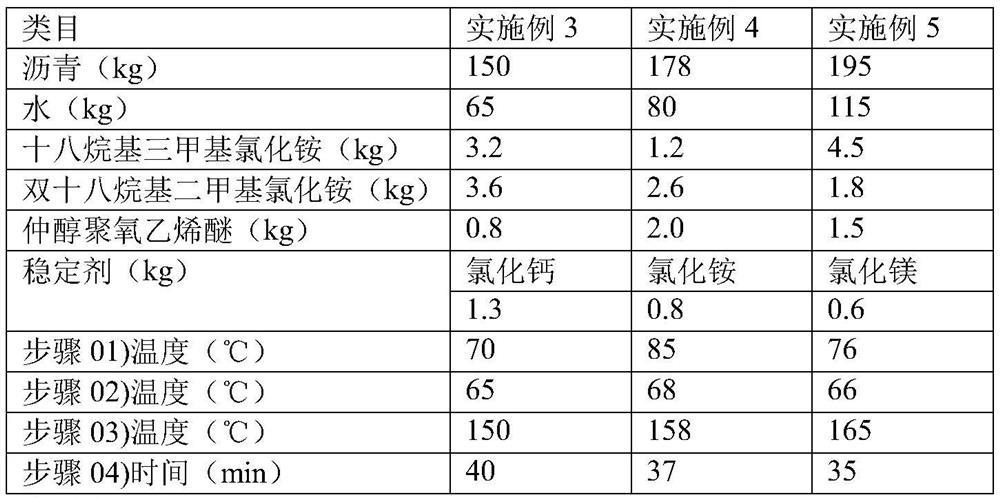

[0073] A construction method for a plastic runway playground, the difference from Example 1 is that the emulsified asphalt is a modified emulsified asphalt, and the modified emulsified asphalt includes the following raw materials: 150kg of asphalt, 65kg of water, 3.2kg of octadecyl trimethyl chloride ammonium chloride, 3.6kg dioctadecyldimethylammonium chloride, 0.8kg secondary alcohol polyoxyethylene ether and 1.3kg stabilizer.

[0074] Wherein, the stabilizing agent selects calcium chloride for use.

[0075] The preparation method of modified emulsified asphalt comprises the following steps:

[0076] Step 01): Heat the water to 70°C, pour in calcium chloride, stir at a speed of 48r / min until dissolved, and obtain the primary mixture;

[0077] Step 02): Let the primary mixture stand at 65°C, add octadecyltrimethylammonium chloride, dioctadecyldimethylammonium chloride and secondary alcohol polyoxyethylene ether, at a speed of 52r / min Stir for 5 minutes to obtain soap liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com